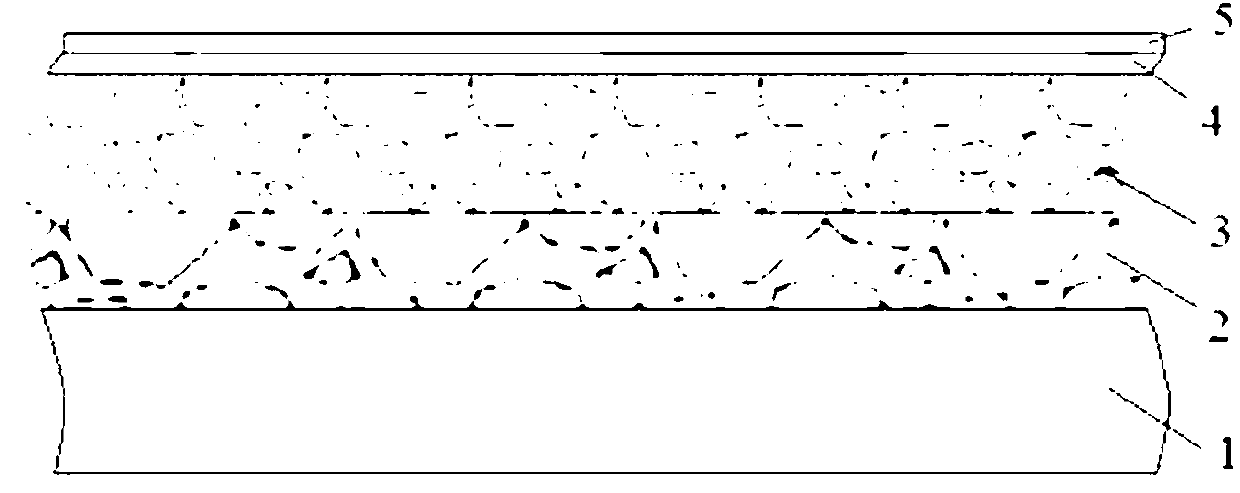

High-simulation mud plate picture workmanship

A production process and clay tablet painting technology, which is applied in the process of producing decorative surface effects, decorative arts, special decorative structures, etc., can solve the problems of lack of experiments, slow production speed, and a large number of other problems, so as to achieve a fine and clear picture and high production efficiency. Fast and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Select the European pine board with a thickness of 7mm and cut it into plate materials; sieve the sand to obtain fine sand with a particle size of 53-44 μm; Fine sand and fine soil get the first mixture; add 500g talcum powder, 50g olive oil, 50g fiber, 15g essence, 150g propionic acid, 100g antioxidant, 500g styrene-acrylic emulsion, 200g elastic emulsion respectively in 10kg of this first mixture Take the first mixture, talcum powder, olive oil, plant fiber, essence, propionic acid, antioxidant, styrene-acrylic emulsion, elastic emulsion and purified water respectively, and stir fully and evenly to obtain coarse mud; sieve sand , to obtain fine sand with a particle size of 26 to 30 μm; sieve the soil to obtain fine soil with a particle size of 19 to 21 μm; mix fine sand and fine soil at a weight ratio of 1:6 to obtain a second mixture; press 10 kg of the second Add 100g talcum powder, 100g olive oil, 10g fiber, 15g essence, 150g propionic acid, 100g antioxidant, 500g ...

Embodiment 2

[0043] Select an extruded polystyrene board with a thickness of 15mm and cut it into plate materials; sieve sand to obtain fine sand with a particle size of 53-44 μm; sieve loess to obtain fine soil with a particle size of 26-30 μm; Fine sand and fine soil get the first mixture; add 800g talcum powder, 90g olive oil, 100g fiber, 20g essence, 200g propionic acid, 140g antioxidant, 1000g styrene-acrylic emulsion, 250g elastic emulsion respectively in this first mixture by 15kg And the ratio of 3500g pure water, take the first mixture, talcum powder, olive oil, plant fiber, essence, propionic acid, antioxidant, styrene-acrylic emulsion, elastic emulsion and purified water respectively, fully and uniformly stir to get coarse mud;

[0044] Sieve sand to obtain fine sand with a particle size of 26-30 μm; sieve loess to obtain fine soil with a particle size of 19-21 μm; mix fine sand and fine soil at a weight ratio of 1:1 to obtain the second mixture; Add 200g talcum powder, 150g oli...

Embodiment 3

[0046] Select an extruded polystyrene board with a thickness of 11mm and cut it into plates; sieve sand to obtain fine sand with a particle size of 53-44 μm; sieve loess to obtain fine soil with a particle size of 26-30 μm; mix according to the weight ratio 1:4 Fine sand and fine soil get the first mixture; add 650g talcum powder, 70g olive oil, 75g fiber, 17.5g essence, 175g propionic acid, 120g antioxidant, 750g styrene-acrylic emulsion, 225g The ratio of the elastic emulsion to 3000g of purified water is obtained by taking the first mixture, talcum powder, olive oil, plant fiber, essence, propionic acid, antioxidant, styrene-acrylic emulsion, elastic emulsion and purified water, and stirring fully and uniformly to obtain coarse mud;

[0047] Sieve sand to obtain fine sand with a particle size of 26-30 μm; sieve loess to obtain fine soil with a particle size of 19-21 μm; mix fine sand and fine soil at a weight ratio of 1:3.5 to obtain the second mixture; Add 150g of talcum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com