Method for preparing mesoporous silicon nanowire by metal nanoparticle auxiliary etching method

A metal nanoparticle and assisted etching technology, which is applied in the coating process of metal materials, the manufacturing of microstructure devices, and the process for producing decorative surface effects, etc., can solve the problems of large-scale integration difficulties, high equipment requirements, and high costs. , to achieve the effect of low cost, huge specific surface area and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

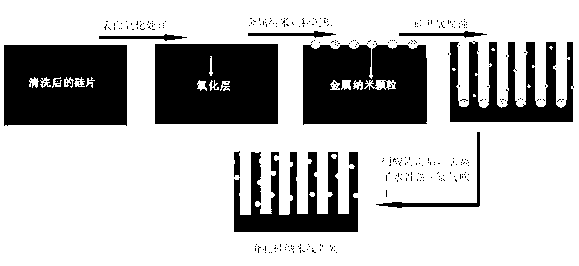

[0024] (1) Silicon wafer pretreatment: ultrasonically clean the monocrystalline silicon wafer (100) with a resistivity of 0.01-0.09Ω·cmp with commercially available analytically pure acetone, toluene, ethanol, and deionized water for 10 minutes in sequence;

[0025] (2) Oxidation treatment of the surface of the silicon wafer: the silicon wafer pretreated in step (1) is oxidized on the surface by conventional thermal oxidation to form an oxide layer, and the existence of the oxide layer is formed by utilizing the mesoporous structure;

[0026] (3) Preparation of corrosion solution: AgNO with a concentration of 1mol / L 3 Solution, hydrofluoric acid with a mass concentration of 10%, H with a concentration of 3mol / L 2 o 2 The corrosion solution is obtained by mixing at a volume ratio of 1:8:1;

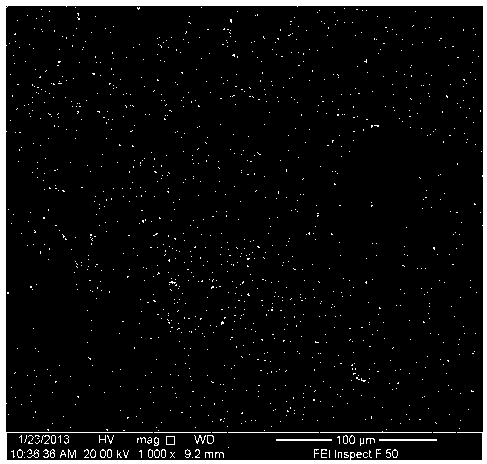

[0027] (4) Preparation of mesoporous silicon nanometers: place the silicon wafer treated with surface oxidation in step (2) in the corrosion solution obtained in step (3) in a dark room t...

Embodiment 2

[0029] (1) Silicon wafer pretreatment: the p-type monocrystalline silicon wafer (111) with a resistivity of 10-100 Ω·cm was ultrasonically cleaned for 10 minutes with commercially available analytically pure acetone, toluene, ethanol, and deionized water in sequence;

[0030] (2) Oxidation treatment on the surface of the silicon wafer: the silicon wafer pretreated in step (1) is subjected to surface oxidation treatment by conventional chemical oxidation to form an oxide layer, and the existence of the oxide layer can utilize the formation of a mesoporous structure;

[0031] (3) Preparation of corrosion solution: KAuCl with a concentration of 1mol / L 4 solution), hydrofluoric acid with a mass concentration of 10%, and HNO with a concentration of 5mol / L 3 5:10:10 is mixed by volume to obtain corrosion solution;

[0032] (4) Preparation of mesoporous silicon nanometers: place the silicon wafer treated with surface oxidation in step (2) in the corrosion solution obtained in step (...

Embodiment 3

[0034] (1) Silicon wafer pretreatment: the n-type single crystal silicon wafer (111) with a resistivity of 0.01Ω·cm was ultrasonically cleaned with commercially available analytically pure acetone, toluene, ethanol, and deionized water for 30 minutes in sequence;

[0035] (2) Oxidation treatment on the surface of the silicon wafer: the silicon wafer pretreated in step (1) is subjected to surface oxidation treatment by conventional electrochemical oxidation to form an oxide layer, and the existence of the oxide layer can utilize the formation of a mesoporous structure;

[0036] (3) Preparation of corrosion solution: HAuCl with a concentration of 1mol / L 4 Solution, hydrofluoric acid with a mass concentration of 30%, Fe(NO with a concentration of 10mol / L 3 ) 3 The corrosion solution is obtained by mixing in a volume ratio of 0.01:0.01:0.2;

[0037] (4) Preparation of mesoporous silicon nanometers: place the silicon wafer treated with surface oxidation in step (2) in the corrosi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com