Radial-flow constructed wetland sludge treatment system and method thereof

A technology of sludge treatment and constructed wetland, which is applied in the directions of sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc. High costs and other problems, achieve the effect of uniform sludge distribution, low construction and operation costs, and remarkable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1, see figure 1 As shown, this radial flow constructed wetland sludge treatment system includes a sludge inlet pipe 1, a regulating tank 2, and four constructed wetland sludge treatment tanks. Four constructed wetland sludge treatment tanks are connected in parallel and connected to the regulating tank 2.

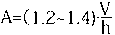

[0039] See figure 1 , 2 As shown, the pool body 16 is round or square, and the material of the pool body 16 is concrete, brickwork, soil, plastic or metal. The inside of the body 16 of the constructed wetland sludge treatment tank is successively laid with an anti-seepage film 6 from bottom to top, a gravel drainage layer 7 for collecting sludge leachate, and a filter layer 8 for purifying sludge leachate. And the sand layer 9 used for the separation of mud and water, above the sand layer 9 is a mud cake layer 10 formed by dried sludge, above the mud cake layer 10 is a sludge layer 11 to be treated, the gravel drainage layer 7, filtration Layer 8 and sand lay...

Embodiment 2

[0047] In the second embodiment, the constructed wetland sludge treatment tank 16 is a plastic bucket with a diameter of 0.82m and a height of 1.5m. It contains 15cm gravel with a diameter of 50mm as a gravel drainage layer, on which is a gravel filter layer with a diameter of 10mm and a thickness of 10cm. Above it is a sand layer with a diameter of 1mm and a thickness of 15cm. Above the sand layer is a mud cake layer. Reeds and cattails are planted. The bottom of the plastic bucket is equipped with a leachate outlet and a vent pipe provides air to the bottom of the wetland. After two months of treatment of the remaining sludge from the sewage treatment plant, the volume of the sludge was reduced by 68%, and the organic content in the sludge was reduced by 23%.

[0048]

[0049] This method of sludge drying and stabilization using a radial flow constructed wetland sludge treatment system is as follows:

[0050] Step 1: The sludge produced by the sewage treatment plant enters the adj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com