Yellow flexible sealing filler and preparation method thereof

A flexible sealing packing, yellow technology, applied in the field of sealing packing, can solve the problems of insufficient fiber strength affecting tensile strength, inability to ensure proper packing, no cracking effect of packing, etc., to achieve excellent resilience, high strength and mold number, the effect of small electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with embodiment the present invention is described in further detail.

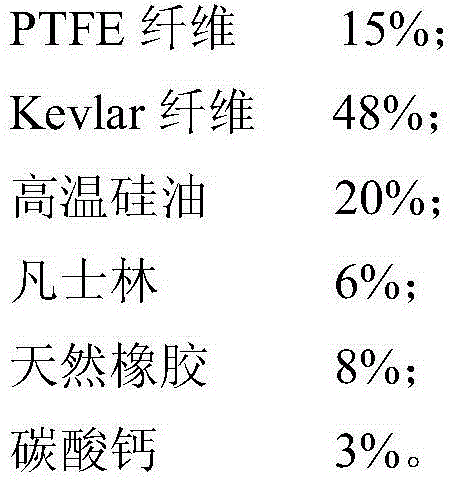

[0017] The yellow flexible sealing packing is composed of PTFE fiber, Kevlar fiber, high-temperature silicone oil, vaseline, natural rubber, and calcium carbonate. The weight ratio of each material is:

[0018]

[0019] The preparation process of the yellow flexible sealing packing is as follows: pulverize PTFE fiber, Kevlar fiber, natural rubber and calcium carbonate in a pulverizer, place the obtained mixed powder in a constant temperature heating container, and stir with a stirring device. When the stirring action is completed to After the mixed powder is evenly mixed, add lubricant and continue to stir. During the stirring process, the container needs to be kept at a constant temperature, and the temperature is always kept between 90 and 180 degrees until the stirring is completed and a muddy product is formed.

[0020] The high-temperature silicone oil in this embodiment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com