A cutting fluid suitable for fluorine-free refrigeration industry and its preparation method

A cutting fluid and industry-leading technology, which is applied in the field of cutting fluid and its preparation, can solve the problems of capillary blockage of refrigeration system, scrapping of refrigeration system, product damage, etc., and achieve the effect of solving capillary blockage, reducing residual volume and good defoaming ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

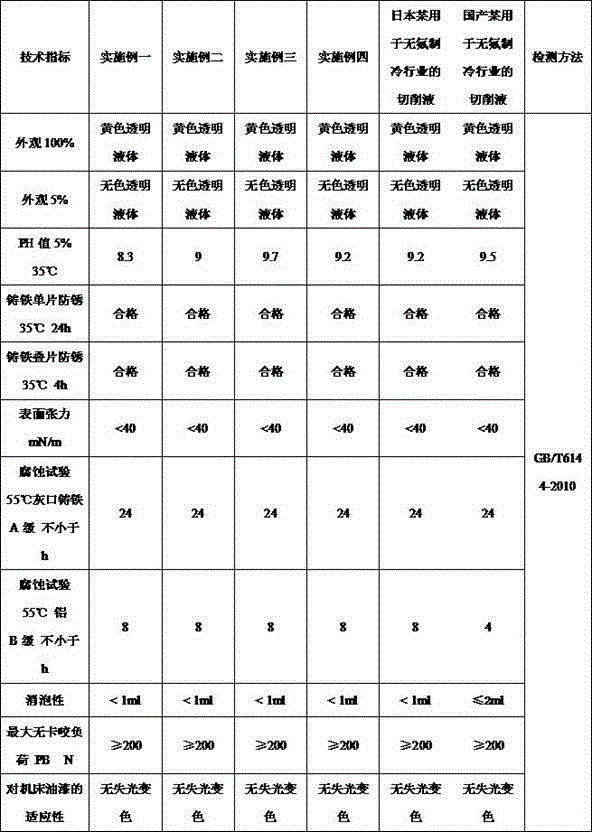

Image

Examples

Embodiment 1

[0022] First, 5 grams of monoethanolamine, 20 grams of fatty acid amide, and 3 grams of lubricating aid were mixed in advance at 55°C for 2 hours; then 50 grams of pure water, 10 grams of triethanolamine, 10 grams of surfactant, benzene 1 gram of triazole, 1 gram of non-silicone oil defoamer, and stir and mix evenly according to the proportion. The order of addition is pure water, triethanolamine, surfactant, benzotriazole, and non-silicone oil defoamer. Minutes, and the stirring time is controlled for 2 hours, and a cutting fluid suitable for the fluorine-free refrigeration industry is obtained.

Embodiment 2

[0024] First, 5 grams of monoethanolamine, 10 grams of fatty acid amide, and 3 grams of lubricating aid were mixed in advance at 60 ° C for 2 hours; then 50 grams of pure water, 15 grams of triethanolamine, 15 grams of surfactant, benzene 1 gram of triazole, 1 gram of non-silicone oil defoamer, and stir and mix evenly according to the proportion. The order of addition is pure water, triethanolamine, surfactant, benzotriazole, and non-silicone oil defoamer. Minutes, and the stirring time is controlled for 2 hours, and a cutting fluid suitable for the fluorine-free refrigeration industry is obtained.

Embodiment 3

[0026] First, 10 grams of monoethanolamine, 5 grams of fatty acid amide, and 5 grams of lubricating aid were pre-stirred and mixed at 55 ° C for 2 hours; then 80 grams of pure water, 3 grams of triethanolamine, 20 grams of surfactant, benzene 1 gram of triazole, 1 gram of non-silicone oil defoamer, and stir and mix evenly according to the proportion. The order of addition is pure water, triethanolamine, surfactant, benzotriazole, and non-silicone oil defoamer. Minutes, and the stirring time is controlled for 2 hours, and a cutting fluid suitable for the fluorine-free refrigeration industry is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com