Method for preparing crystalline silicon battery pieces through multistep gradient diffusion method

A crystalline silicon battery and gradient diffusion technology, which is applied in the manufacture of circuits, electrical components, semiconductors/solid-state devices, etc., can solve the problems of battery conversion efficiency not being significantly improved, and the lifetime of minority carriers is low, so as to improve conductivity and reduce carrier life. Effects of life improvement and conversion efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

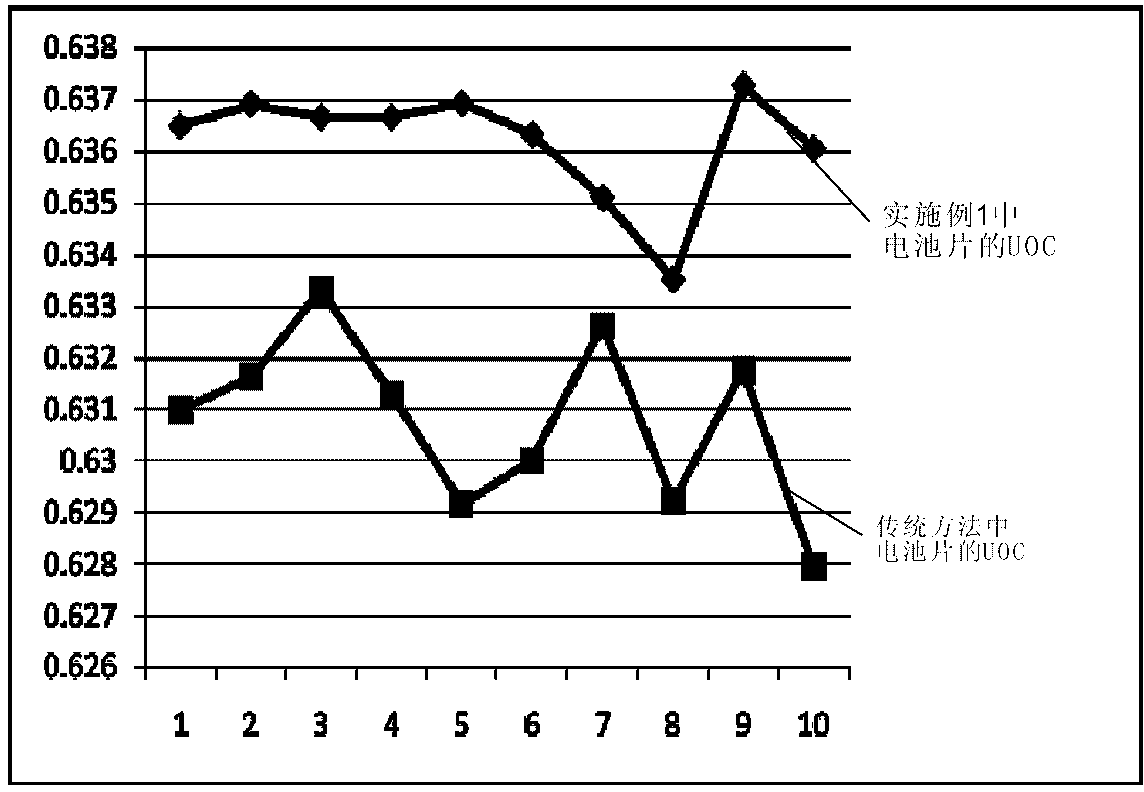

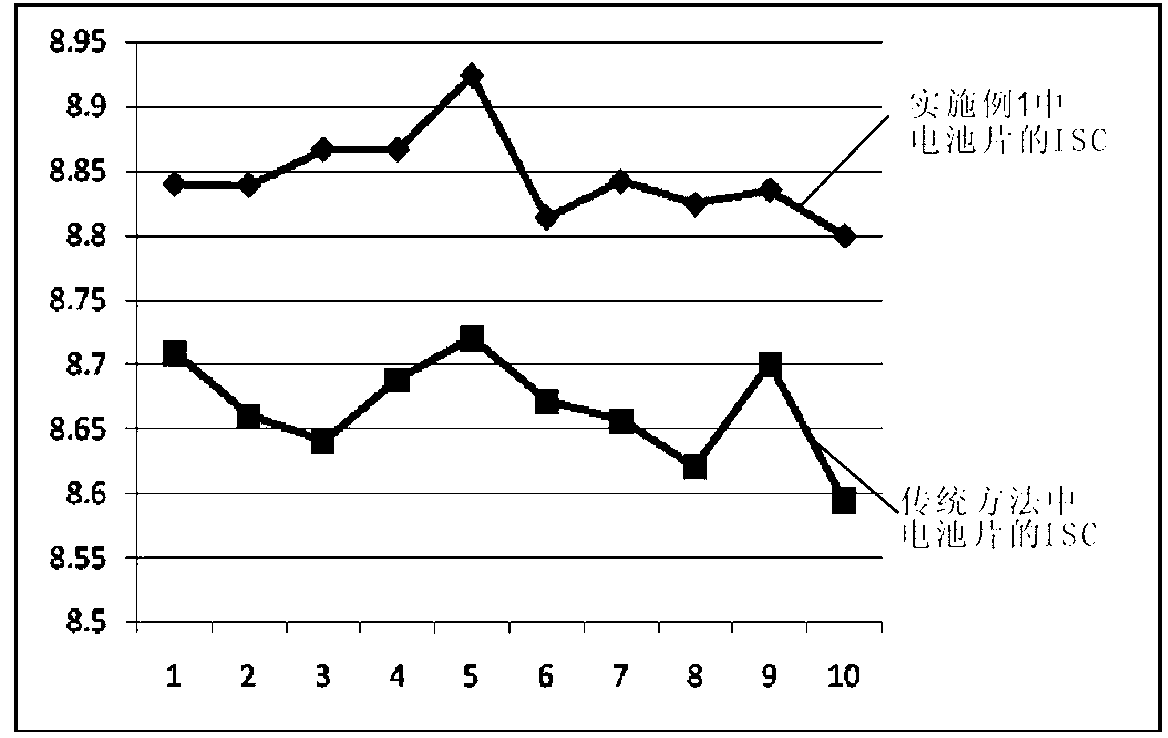

Embodiment 1

[0016] A multi-step gradient diffusion method is used to prepare crystalline silicon cells, and the gradient diffusion method is used to do high-temperature phosphorus doping on the surface of P-type crystalline silicon to obtain N-type crystalline silicon and form a P-N junction, including the following steps,

[0017] 1) Pour 300 PCS of P-type crystalline silicon into the pre-set 800°C furnace tube, and at the same time, feed nitrogen at a rate of 17.8-18.2L / min, and keep warm for 600s;

[0018] 2) Raise the temperature in the furnace tube to 860°C in two steps. First, raise the temperature in the furnace from 800°C to 820°C. At the same time, nitrogen and oxygen are introduced. The nitrogen and oxygen are respectively 18.0L / min and 0.8L / min The speed is passed into the furnace for 250s; then the temperature is raised from 820°C to 860°C, and nitrogen and oxygen are passed into the furnace at the same time. The nitrogen and oxygen are respectively passed into the furnace at a...

Embodiment 2

[0025] A multi-step gradient diffusion method is used to prepare crystalline silicon cells, and the gradient diffusion method is used to do high-temperature phosphorus doping on the surface of P-type crystalline silicon to obtain N-type crystalline silicon and form a P-N junction, including the following steps,

[0026] 1) Pour 400PCS of P-type crystalline silicon into the pre-set 800°C furnace tube, and at the same time, feed nitrogen at a rate of 18L / min and keep it warm for 800s;

[0027] 2) Raise the temperature in the furnace tube to 860°C in two steps, first raise the temperature in the furnace from 800°C to 820°C, and at the same time feed nitrogen and oxygen, of which nitrogen and oxygen are respectively at a rate of 18L / min and 0.9L / min Pass it into the furnace for 300s; then raise the temperature from 820°C to 860°C, and feed nitrogen and oxygen at the same time, wherein nitrogen and oxygen are passed into the furnace at a rate of 18L / min and 0.9L / min respectively, T...

Embodiment 3

[0034] A multi-step gradient diffusion method is used to prepare crystalline silicon cells, and the gradient diffusion method is used to do high-temperature phosphorus doping on the surface of P-type crystalline silicon to obtain N-type crystalline silicon and form a P-N junction, including the following steps,

[0035] 1) Pour 500PCS of P-type crystalline silicon into the pre-set 800°C furnace tube, and at the same time, feed nitrogen at a rate of 18.2L / min, and keep it warm for 900s;

[0036] 2) Raise the temperature in the furnace tube to 860°C in two steps, first raise the temperature in the furnace from 800°C to 820°C, and at the same time feed nitrogen and oxygen, of which nitrogen and oxygen are respectively 18.6L / min and 1.0L / min The speed is passed into the furnace, and the feeding time is 350s; then the temperature is raised from 820°C to 860°C, and nitrogen and oxygen are passed in at the same time, of which nitrogen and oxygen are respectively passed into the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com