Potassium copper manganese oxide and preparation method thereof, and positive electrode as well as preparation method and application thereof

A technology of copper manganese oxide and positive electrode, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unstable skeleton structure, poor cycle stability, and large potassium ion size, and achieve good cycle stability and improve work efficiency. Effect of improving voltage and cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of the potassium copper manganese oxide, comprising the following steps:

[0032] Will K 2 CO 3 , CuO and MnO 2 Mix and grind to obtain a raw material mixture; the K 2 CO 3 , CuO and MnO 2 The molar ratio is 17:17:33;

[0033] The raw material mixture is sequentially subjected to molding and sintering treatment to obtain potassium copper manganese oxide; the sintering temperature is 700-1000° C., and the sintering time is 15 hours.

[0034] The present invention will K 2 CO 3 , CuO and MnO 2 Mix and grind to obtain a raw material mixture. In the present invention, the K 2 CO 3 , CuO and MnO 2 The molar ratio is 17:17:33. In the present invention, the K 2 CO 3 , CuO and MnO 2 There is no special requirement for the source of , and commercially available products well known to those skilled in the art can be used. The present invention has no special requirements on the specific implementation of the mixing and ...

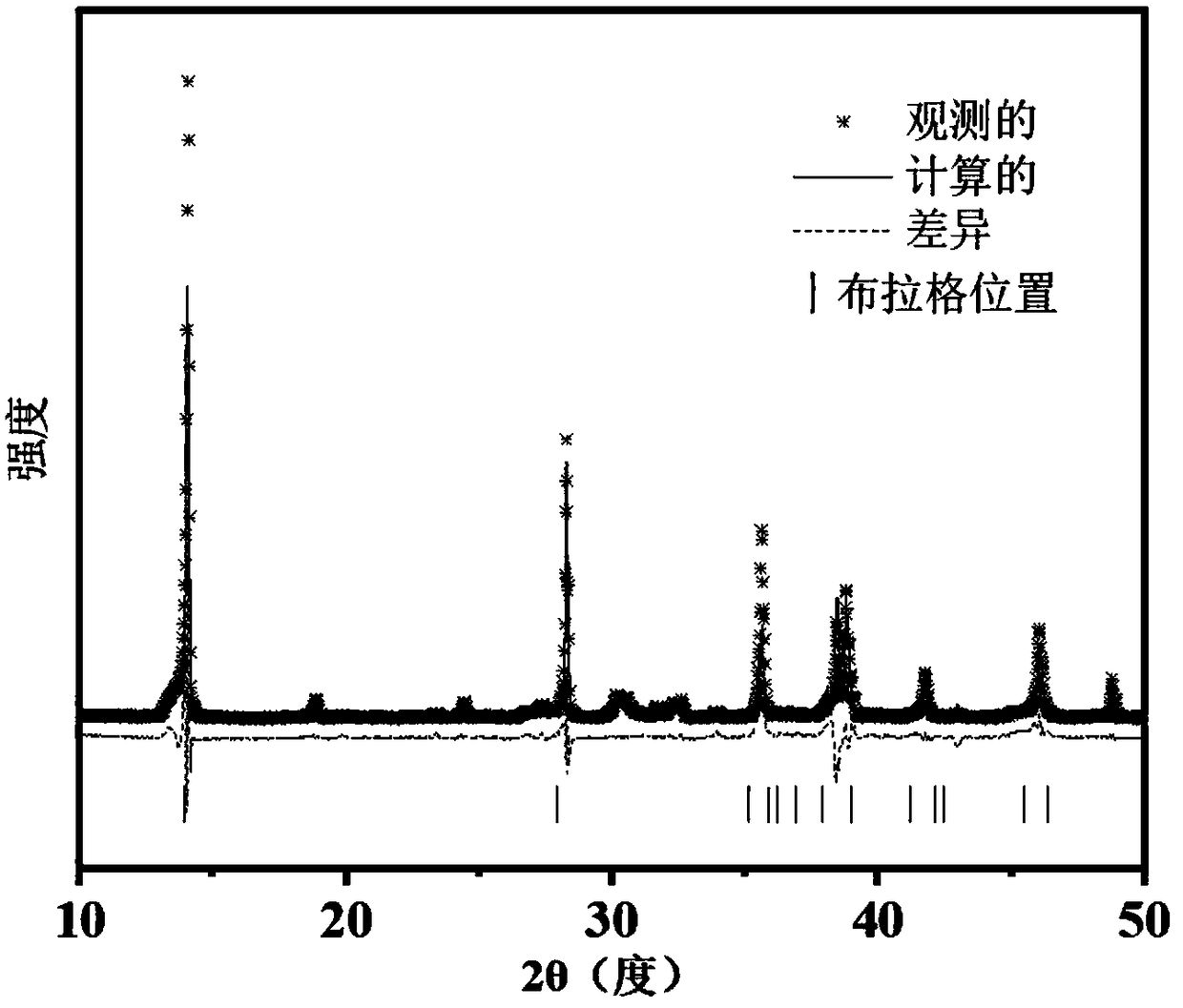

Embodiment 1

[0067] According to K 2 CO 3 , CuO and MnO 2 The molar ratio of 17:17:33 weighed K 2 CO 3 , CuO and MnO 2 , put these three raw materials in an agate mortar for half an hour to make them evenly mixed, then press the mixture into a disc with a thickness of about 1.3cm under 20MPa, put the disc in a corundum porcelain boat and place it in the Sintering at 700-1000° C. for 15 hours in a muffle furnace to obtain a sintered product. The prepared sintered product was analyzed by XRD, the results are as follows figure 1 As shown, the structure refinement of the X-ray diffraction peaks, and the comparison between the detected and calculated values, can confirm that the structure conforms to the Ccmm space group (ICSD 156080), and the lattice parameters are The Rwp value is 13.84. From this, it can be seen that the target product with a layered structure was obtained.

[0068] Grinding the sintered product to obtain K with a particle size of 100-500nm 0.68 Cu 0.34 mn 0.66 o...

Embodiment 2

[0070] The K obtained in Example 1 0.68 Cu 0.34 mn 0.66 o 2 Grinding to obtain K with a particle size of 100-500nm 0.68 Cu 0.34 mn 0.66 o 2 powder.

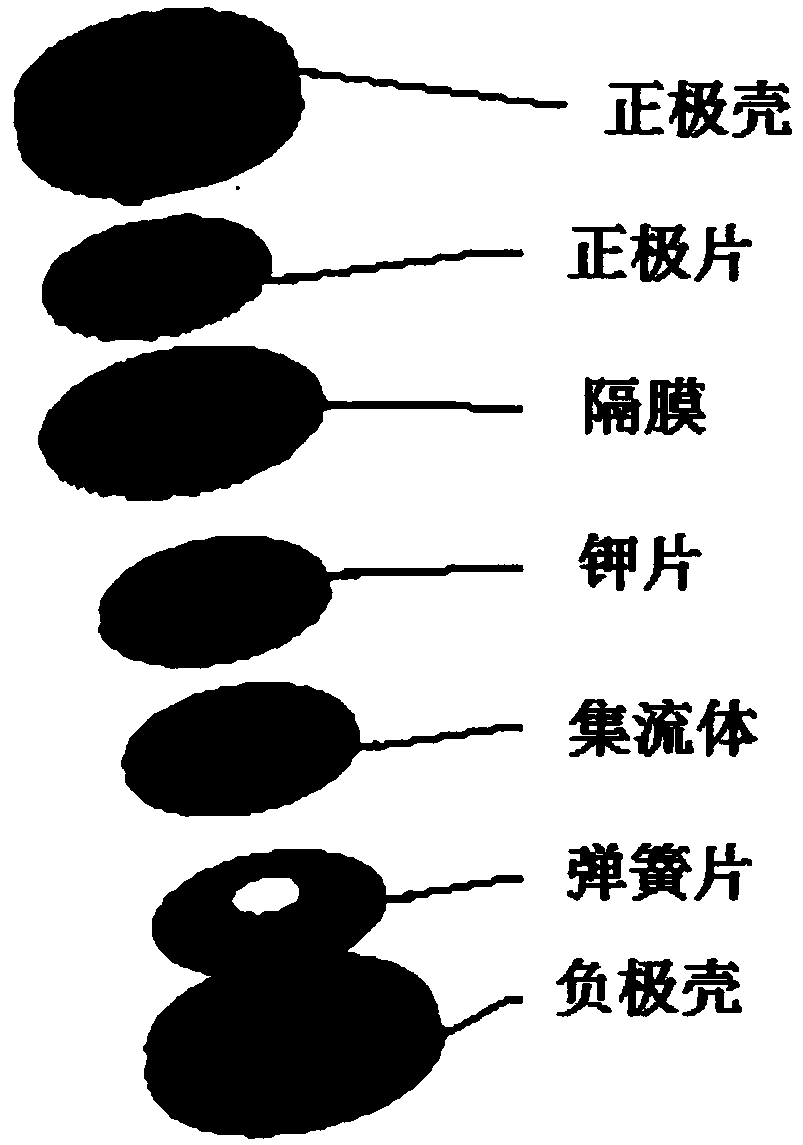

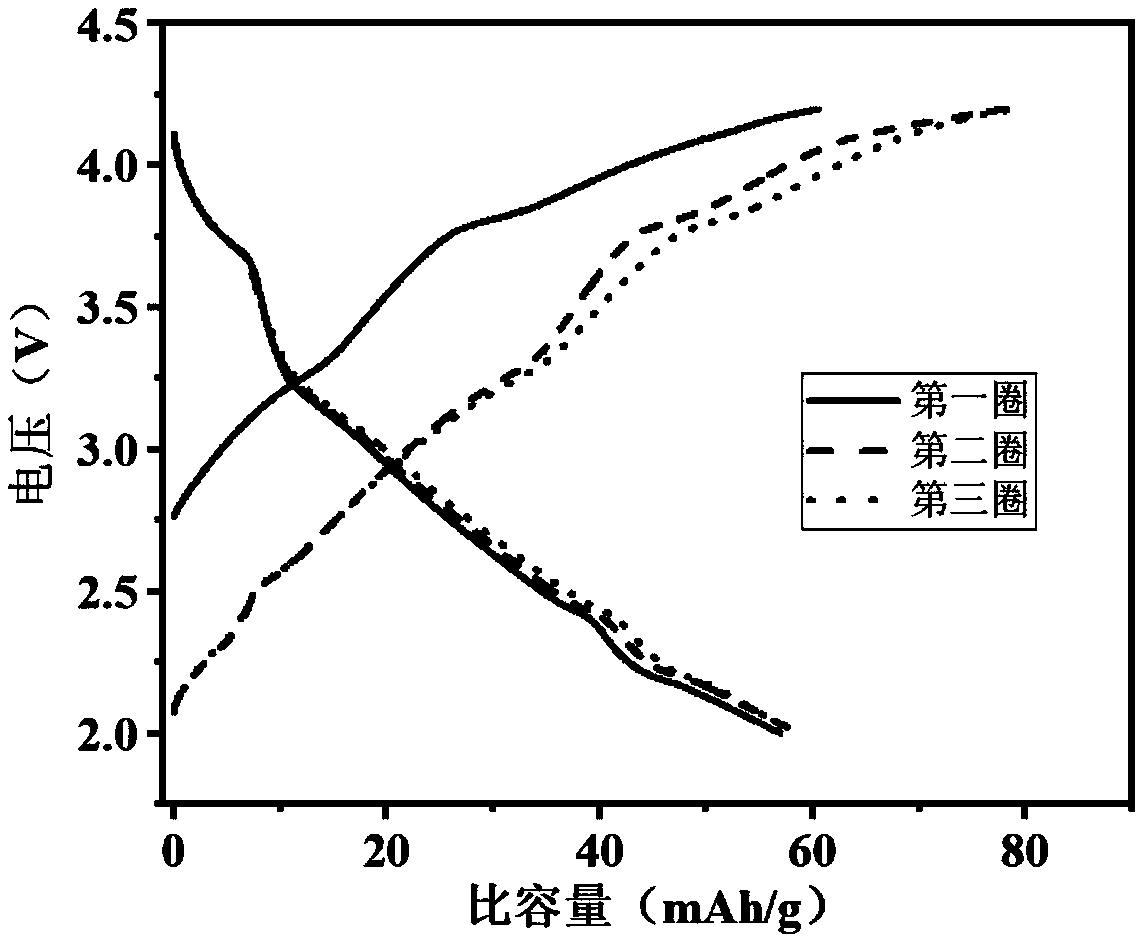

[0071] Will K 0.68 Cu 0.34 mn 0.66 o 2The powder is mixed with conductive additive Super P and polyvinylidene fluoride at a mass ratio of 8:1:1, wherein polyvinylidene fluoride is provided in the form of a PVDF organic solution with a mass fraction of 7%, and N-methyl-2-pyrrolidone is used as Solvent, grind in an agate mortar for 15 minutes, until it is well mixed into a slurry. Use a scraper to evenly coat the ground slurry on the aluminum foil cleaned with alcohol cotton, and dry the coated electrode material in a vacuum oven at 100-120°C for 12 hours. The electrode material taken out of the oven needs to be Press at 10MPa for 5 minutes to ensure that the electrode material will not be de-powdered during the cycle and affect the cycle performance of the battery. Cut the pressed positive electrode material into 8×8mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com