Flame-retardant thermally-conductive adhesive sheet

A heat-conductive and flame-retardant technology, applied in the field of flame-retardant heat-conductive adhesive sheets, can solve the problems of the adhesive layer becoming hard and adhesive properties, decline, loss of fluidity of the adhesive composition, etc. Excellent strength, high flame retardancy, and excellent thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

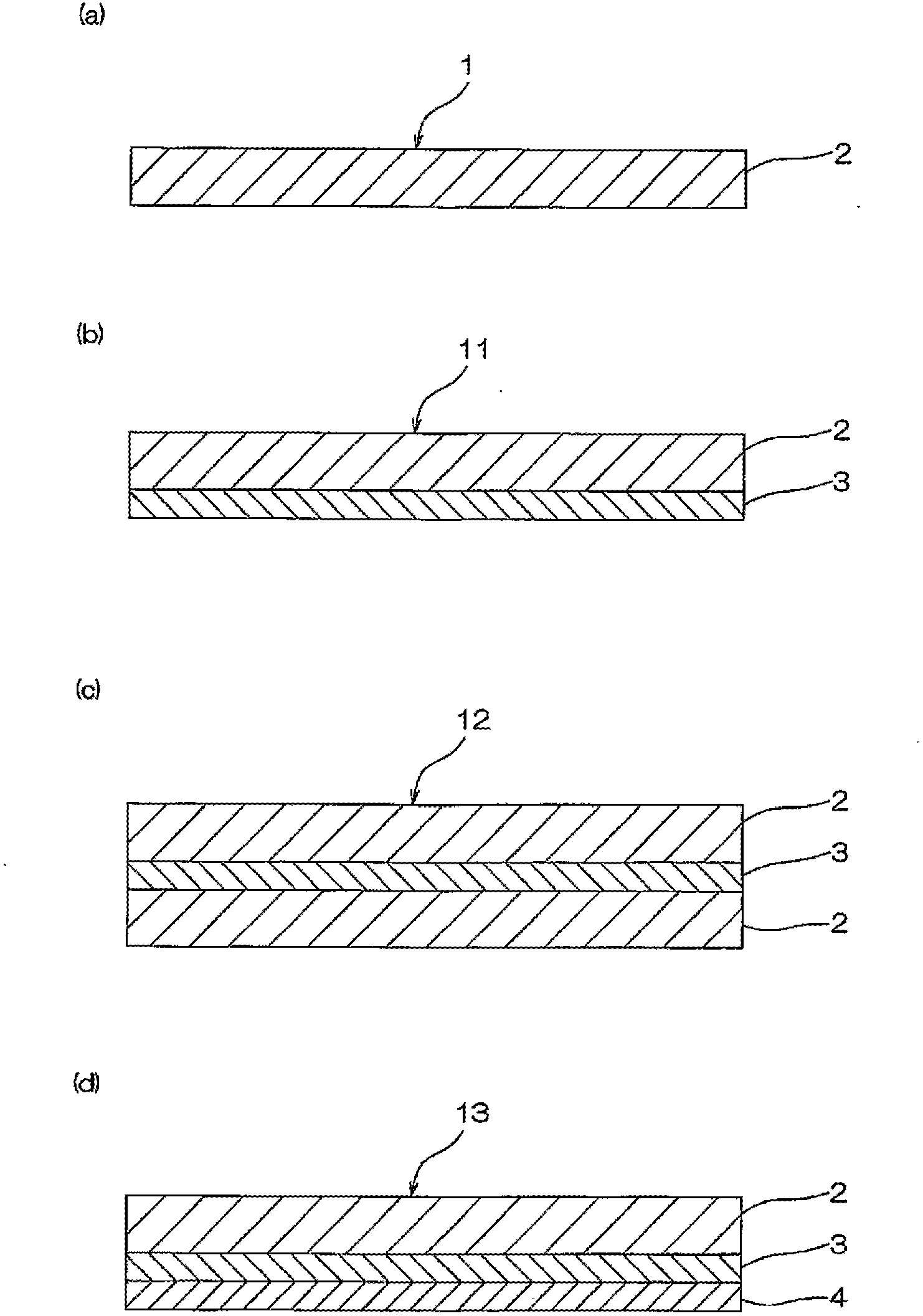

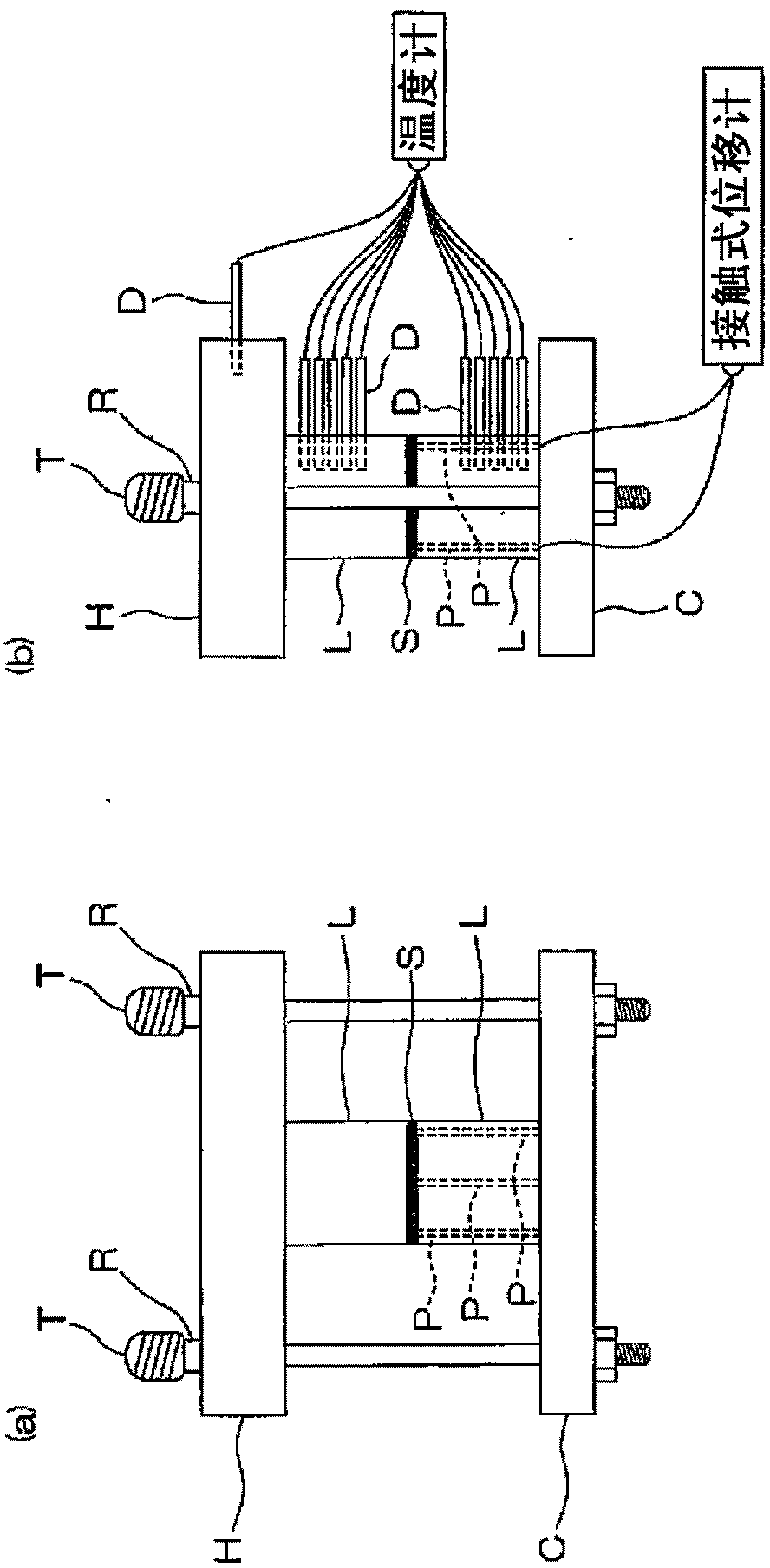

Method used

Image

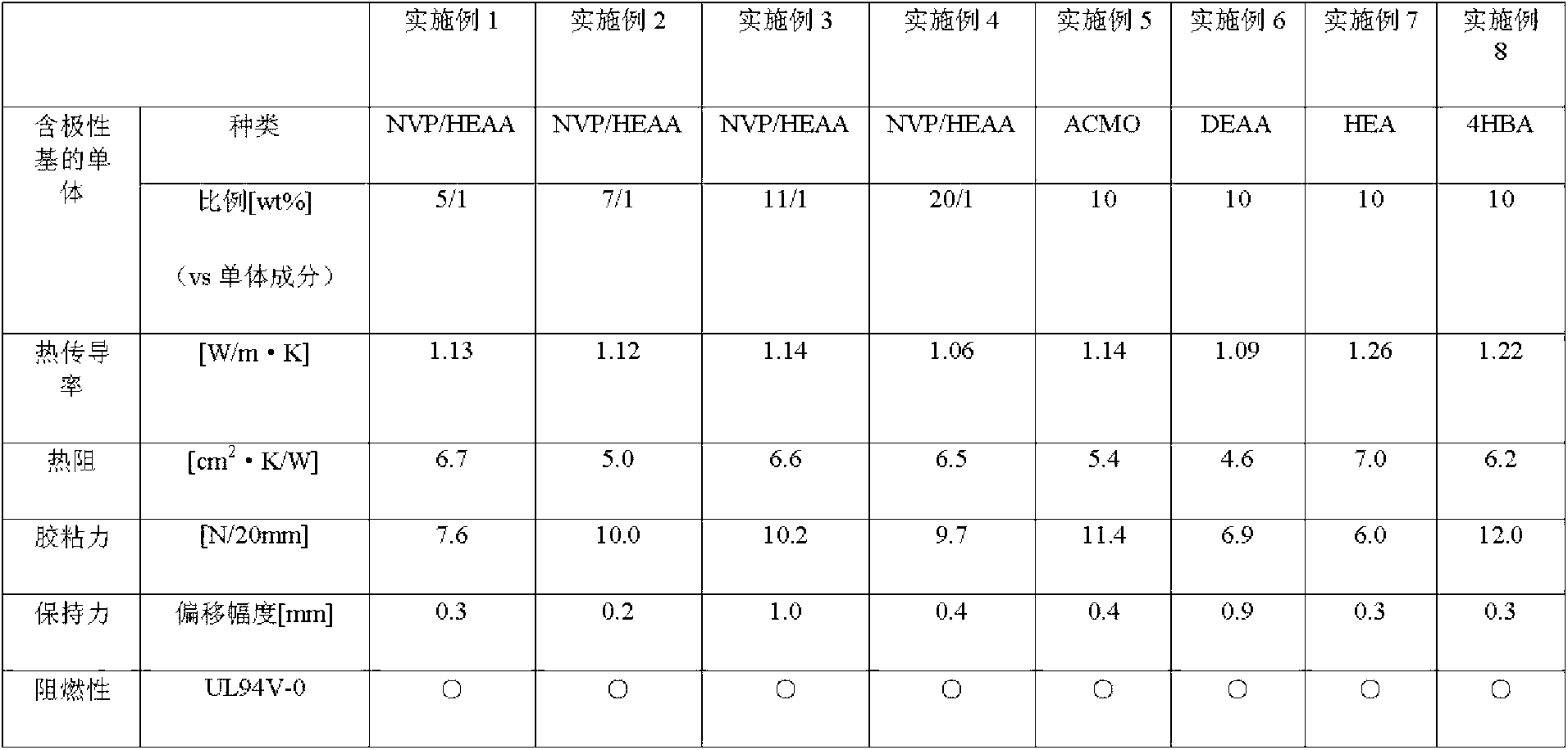

Examples

Embodiment 1

[0149] 82 parts by weight of 2-ethylhexyl acrylate and 12 parts by weight of 2-methoxyethyl acrylate as monomer components, N-vinyl-2-pyrrolidone (NVP) as a polar group-containing monomer 5 parts by weight and 1 part by weight of hydroxyethylacrylamide (HEAA) were mixed with 0.05 parts by weight of the product name "IRGACURE651" (manufactured by Ciba Japan Co., Ltd.) as a photopolymerization initiator and the product name "IRGACURE184" (manufactured by Ciba Japan Co., Ltd.) 0.05 parts by weight, and then irradiated with ultraviolet light until the viscosity (BH viscometer No. 5 rotor, 10 rpm, measurement temperature 30°C) reached about 20 Pa·s, and prepared a partially polymerized combination matter (slurry).

[0150] 0.05 parts by weight of dipentaerythritol hexaacrylate as a polyfunctional monomer, trade name "KAYARAD DPHA-40H" (manufactured by Nippon Kayaku Co., Ltd.), and trade name "Plysurf A212E" ( Daiichi Kogyo Pharmaceutical Co., Ltd.) 1 part by weight. Furthermore, ...

Embodiment 2

[0153] In Example 1, 82 parts by weight of 2-ethylhexyl acrylate and 12 parts by weight of 2-methoxyethyl acrylate as monomer components, N-vinyl-2 - Change 5 parts by weight of pyrrolidone (NVP) and 1 part by weight of hydroxyethylacrylamide (HEAA) to 80 parts by weight of 2-ethylhexyl acrylate and 12 parts by weight of 2-methoxyethyl acrylate, as polar group-containing In addition to 7 parts by weight of N-vinyl-2-pyrrolidone (NVP) and 1 part by weight of hydroxyethylacrylamide (HEAA), the same recipe as in Example 1 was used to produce flame-retardant thermal conductivity adhesive sheet. The glass transition temperature of the acrylic polymer is -61.1°C.

Embodiment 3

[0155] In Example 1, 82 parts by weight of 2-ethylhexyl acrylate and 12 parts by weight of 2-methoxyethyl acrylate as monomer components, N-vinyl-2 - Change 5 parts by weight of pyrrolidone (NVP) and 1 part by weight of hydroxyethylacrylamide (HEAA) to 77 parts by weight of 2-ethylhexyl acrylate and 11 parts by weight of 2-methoxyethyl acrylate, as polar group-containing In addition to 11 parts by weight of N-vinyl-2-pyrrolidone (NVP) and 1 part by weight of hydroxyethylacrylamide (HEAA), a flame-retardant heat-conducting Adhesive tablets. The glass transition temperature of the acrylic polymer was -58.0°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com