Method for reconstituting tobacco leaves by paper making method based on membrane separation technique

A technology of reconstituted tobacco leaf and papermaking method, which is applied in the field of improving the sensory quality of tobacco sheets, which can solve the problems of flat cigarette aroma, poor internal quality, and high tobacco tar, and achieve the effects of normal temperature operation amplification, high efficiency energy consumption, and product grade improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

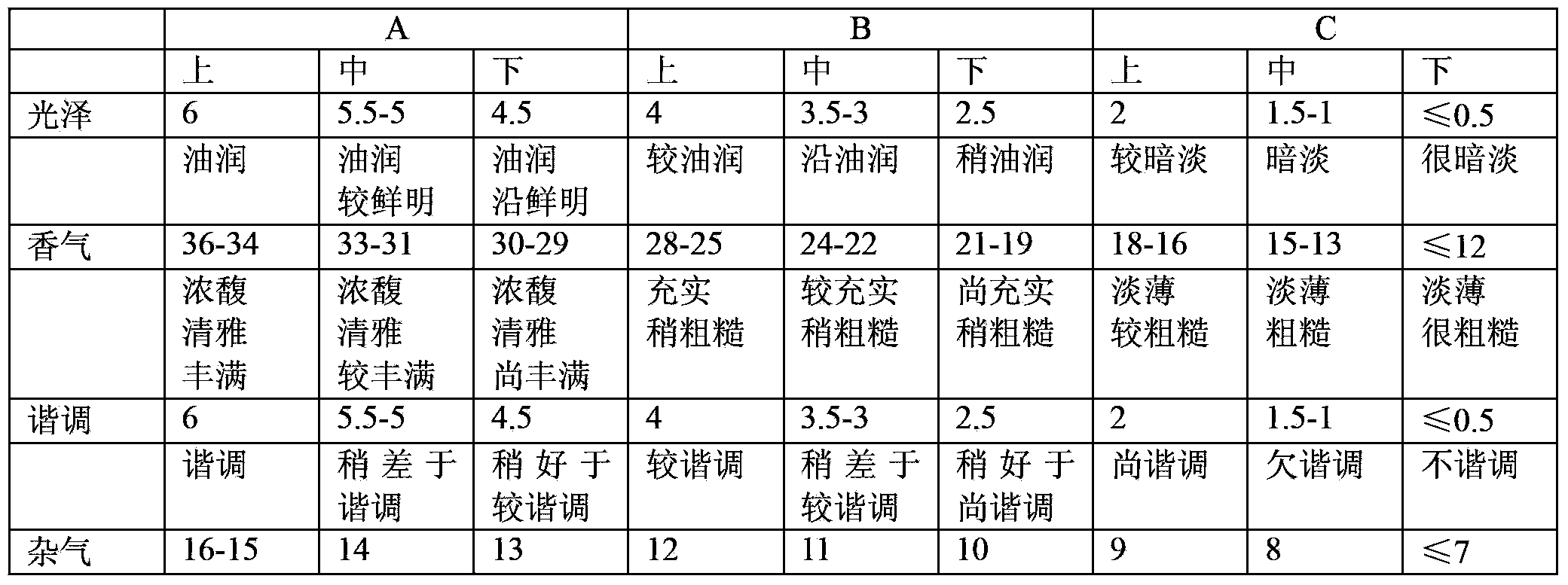

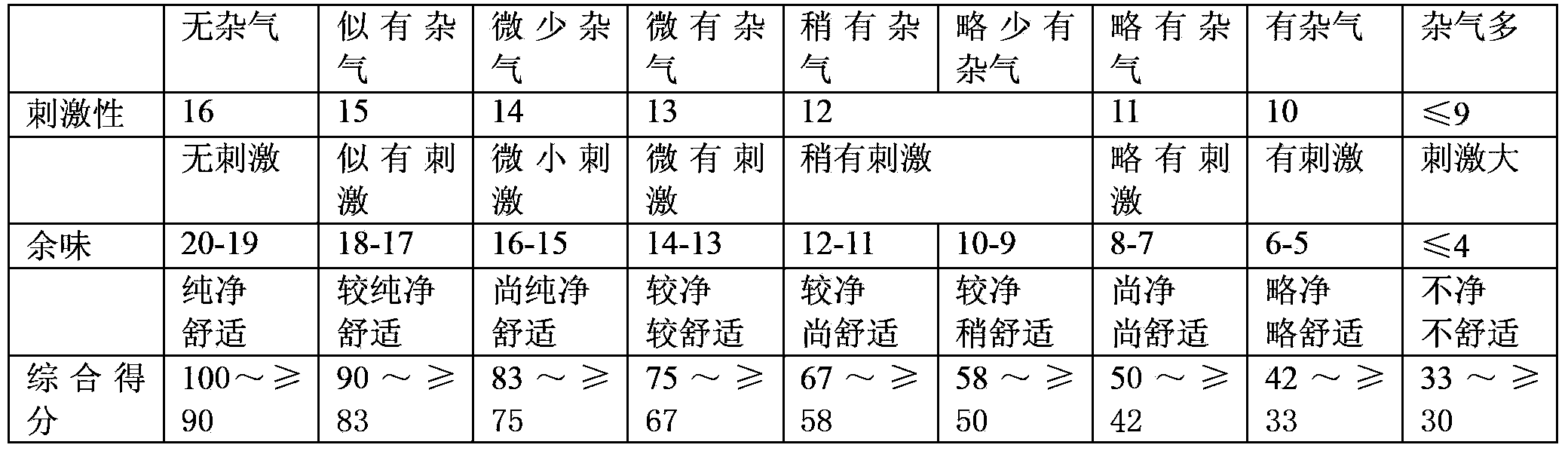

Embodiment 1

[0028]Metal impurities in tobacco stems, tobacco powder and low-grade tobacco leaf raw materials are removed by iron removal equipment, non-metallic materials are removed by foreign matter removal machines, rot and mildew are removed manually, and the screened raw materials are washed and removed by water. Miscellaneous to get the raw material after pretreatment. The treated tobacco stems, tobacco leaves, tobacco powder and water are respectively subjected to countercurrent extraction at a ratio of 1:5. The extraction water temperature is 55°C, and the extraction is performed twice for 30 minutes each time. The extraction waste residue of tobacco stems is discharged, and the tobacco leaves, The leaching waste residue is recycled, and the solid phase is screened through a vibrating sieve to screen out the larger waste residue that is not suitable for papermaking in the solid phase, and the paper-like substrate is made through conventional beating and papermaking processes. The ...

Embodiment 2

[0030] Metal impurities in tobacco stems, tobacco powder and low-grade tobacco leaf raw materials are removed by iron removal equipment, non-metallic materials are removed by foreign matter removal machines, rot and mildew are removed manually, and the screened raw materials are washed and removed by water. Miscellaneous to get the raw material after pretreatment. The treated tobacco stems, tobacco leaves, tobacco powder and water were respectively subjected to countercurrent extraction at a ratio of 1:3. The extraction water temperature was 65°C, and the extraction was carried out 3 times for 15 minutes each time. The tobacco stem extraction waste residue was discharged, and the tobacco leaves, The leaching waste residue is recycled, and the solid phase is screened through a vibrating sieve to screen out the larger waste residue that is not suitable for papermaking in the solid phase, and the paper-like substrate is made through conventional beating and papermaking processes. ...

Embodiment 3

[0032] Metal impurities in tobacco stems, tobacco powder and low-grade tobacco leaf raw materials are removed by iron removal equipment, non-metallic materials are removed by foreign matter removal machines, rot and mildew are removed manually, and the screened raw materials are washed and removed by water. Miscellaneous to get the raw material after pretreatment. The treated tobacco stems, tobacco leaves, tobacco powder and water were respectively subjected to countercurrent extraction at a ratio of 1:7. The extraction water temperature was 55°C, and the extraction was performed once for 30 minutes each time. The tobacco stem extraction waste residue was discharged, and the tobacco leaves, The leaching waste residue is recycled, and the solid phase is screened through a vibrating sieve to screen out the larger waste residue that is not suitable for papermaking in the solid phase, and the paper-like substrate is made through conventional beating and papermaking processes. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com