Manufacturing method of straight-seam bi-metal composite welded pipe used for delivering petroleum and natural gas

A technology for oil and gas and composite welded pipes, which is applied in the field of manufacturing straight seam bimetal composite welded pipes. Layer corrosion resistance, the effect of reducing product cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

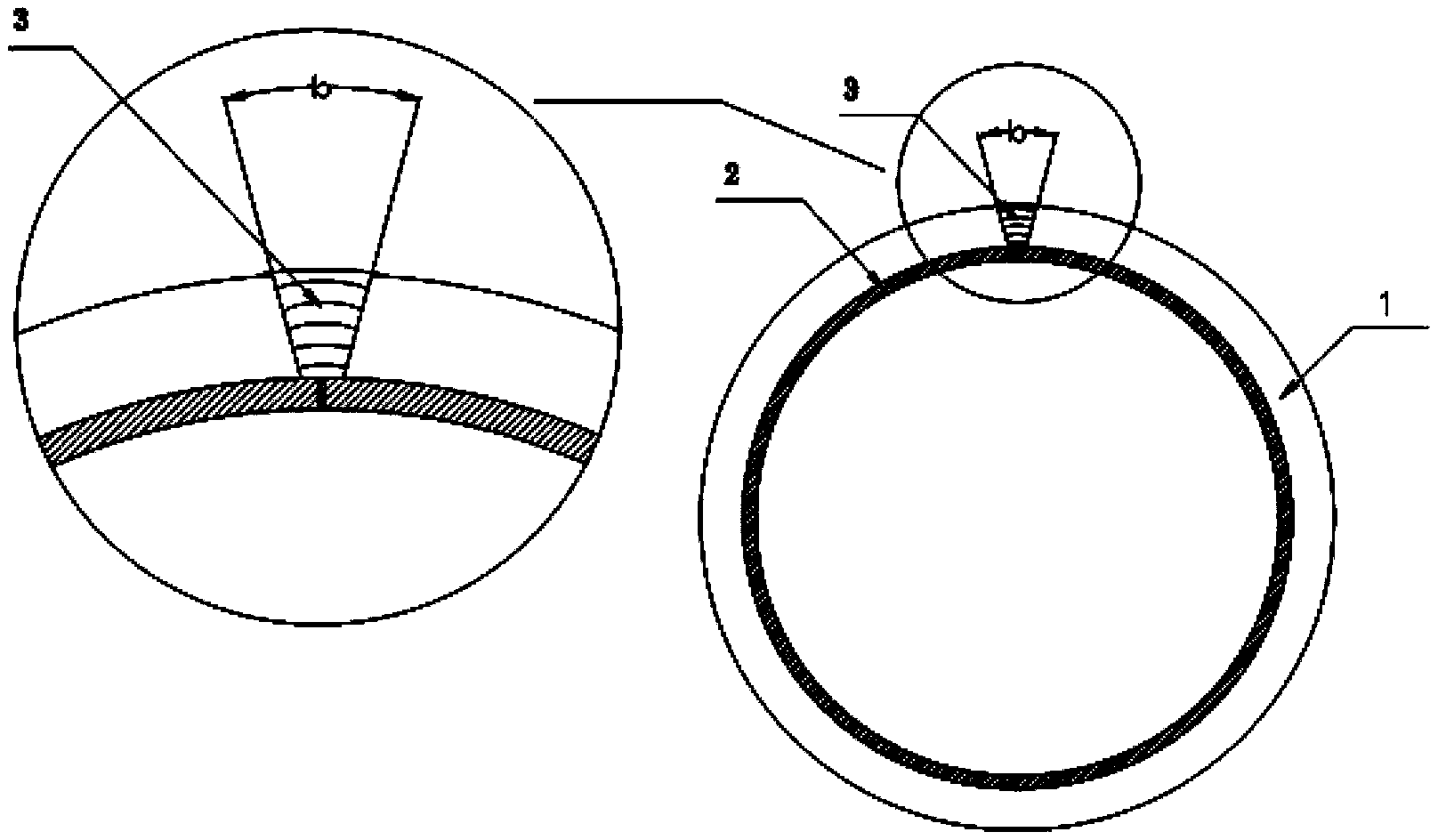

[0017] Example 1: Using pure titanium TA1 / X65 bimetal composite plate as raw material (pure titanium TA1 thickness 2 mm, X 65 thickness 10 mm), adopt V-shaped composite groove welding process to manufacture straight seam bimetal composite welded pipe. The angle of the groove is 30°. After the pipe is formed, the gap between the stainless steel cladding welds is 1mm, and the bevel does not extend to the stainless steel plate layer, so that a 3mm wide boss is left on both sides of the cladding weld to prevent cladding. During welding, the carbon steel composition of the base layer transitions to the cladding layer. First use TIG welding method, pure titanium welding wire TA1, single-sided welding and double-sided forming process to weld the steel clad layer; then use TIG welding method, pure Cu and pure V welding wire to weld the transition layer; finally use MAG or SAW welding method to weld the base layer, Welding material is H08Mn 2 SiA, MAG welding wire diameter is 1.2mm, S...

Embodiment 2

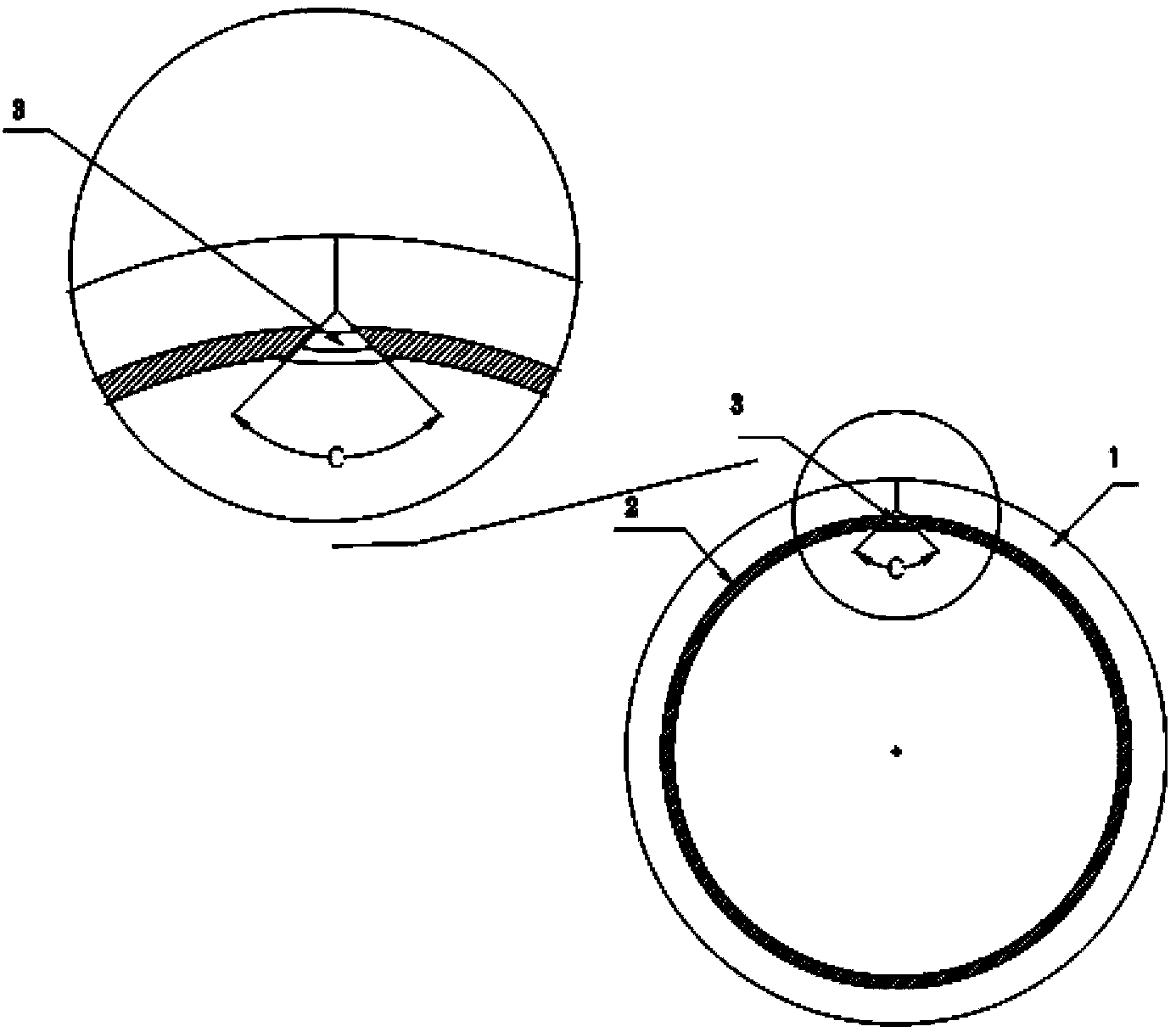

[0020] Example 2: Using 316L / X 65 bimetal composite plate as raw material (the thickness of 316L stainless steel plate is 2 mm, and the thickness of X 65 pipeline steel plate is 10 mm), the straight seam bimetal composite welded pipe is manufactured by Y-groove welding process. The single-side angle of the groove is 45°, and the base layer has a blunt edge of 7mm. After the pipe is formed, the base layer is welded by plasma welding, and then the transition layer and the cladding layer are welded by TIG. The multilayer uses ER316L welding wire, the transition layer uses ER309 welding wire, and the base welding material is H08Mn 2 SiA, the wire diameter is 1.2mm. The specific welding process parameters are shown in the table below:

[0021]

[0022] Test results of mechanical properties of welded pipe: tensile strength 680MPa, 0 ℃ impact toughness weld seam 110J, heat-affected zone 230J, weld seam forward and reverse bending 180 degrees without cracks. The corrosion test ...

Embodiment 3

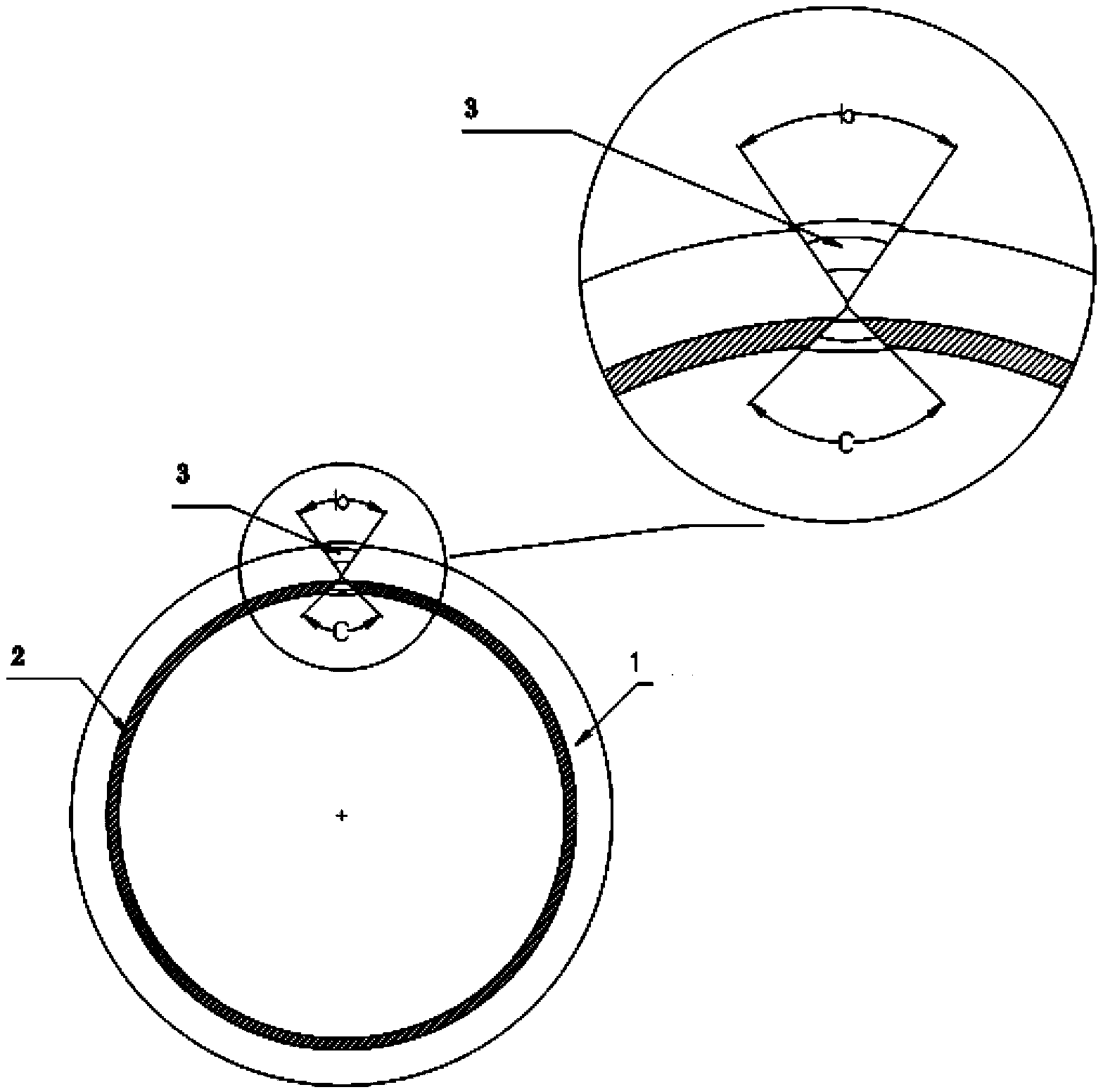

[0023] Example 3: Using 2205 / X70 bimetal clad plate as raw material (the thickness of 2205 stainless steel plate is 2 mm, and the thickness of X70 pipeline steel plate is 10 mm), the straight seam bimetal clad welded pipe is manufactured by X-groove welding process. The single-side crack angle of the base layer is 35°, and the single-side groove angle of the composite layer is 45°. There is a 1mm blunt edge at the base layer near the composite layer. Use TIG welding to weld the cladding, welding wire is ER2209, and finally use MAG welding or SAW welding to weld the base layer, welding wire is H08Mn 2 SiA.

[0024]

[0025] Test results of mechanical properties of welded pipe: tensile strength 655MPa, 0°C impact toughness weld seam 105J, heat-affected zone 210J, weld seam forward and reverse bending 180 degrees without cracks. The corrosion test is carried out according to the standard GB / T 4334-2008, boiled in sulfuric acid-copper sulfate solution for 72 hours, no cracks w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap