Electroslag welding solid wire for low-temperature steel plate

A technology of solid welding wire and electroslag welding, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve the problems of slow cooling rate of weld seam, coarsening of weld seam structure, deterioration of low temperature toughness of weld seam, etc. problem, to achieve good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A 100-ton electric furnace is used to make steel through continuous casting to produce a billet, and a solid core wire with a diameter of 1.6mm is produced through rolling, wire drawing, copper plating and other processes. The main chemical composition (weight percent) of the welding wire is: C0.06, Si0.42, Mn0.87, P0.013, S0.007, Ni4.2, Mo0.45, N0.0045, Zr0.02, Ti0. 2, B0.008, the balance is iron and unavoidable impurities.

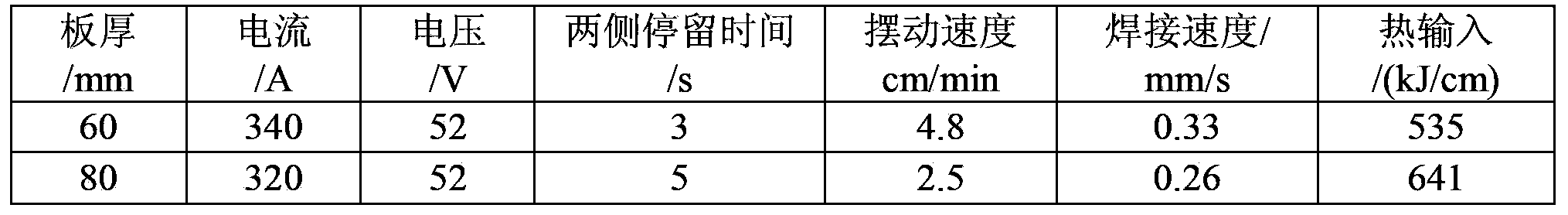

[0030] The electroslag welding process parameters are shown in Table 1. Vertical butt welding tests were carried out on ship plate EH40 with thickness specifications of 60mm and 80mm respectively. The composition of the steel plate contains 0.08%C, 0.25%Si, 1.5%Mn, 0.01%P, 0.006%S, and an appropriate amount of elements such as Nb and Ti; the yield strength of the steel plate is ≥400MPa, the tensile strength is ≥520MPa, and the elongation is ≥26% , -40 ℃ impact energy ≥ 300J.

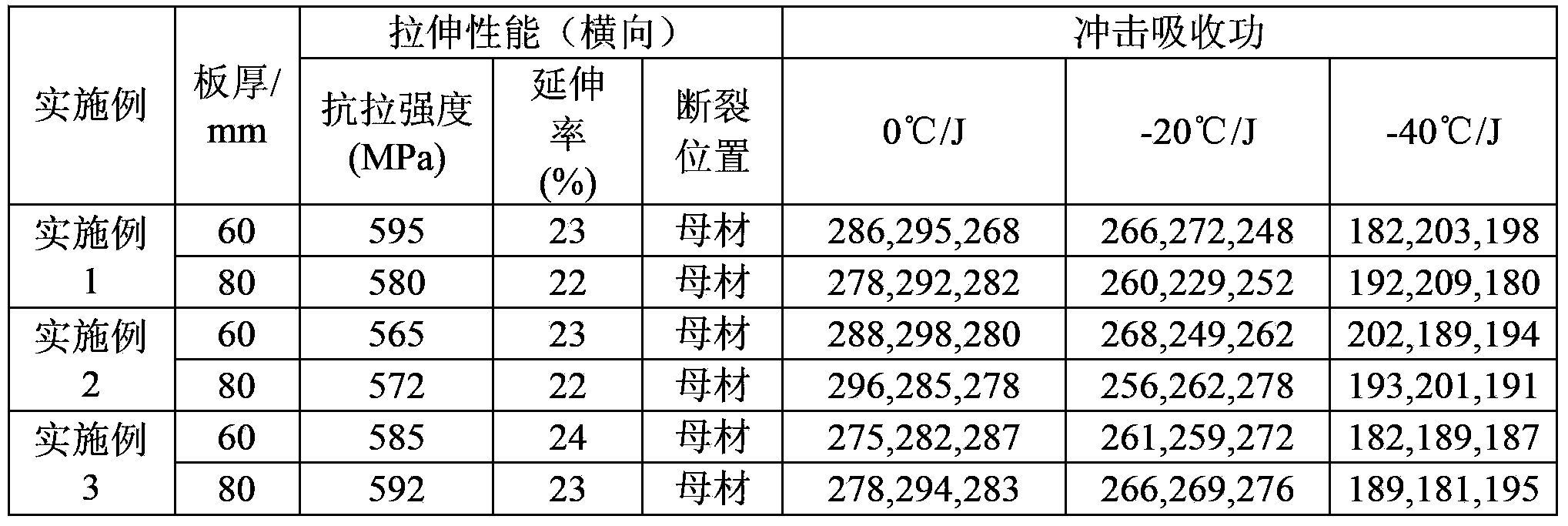

[0031] After welding, the electroslag welded joints were sampled for ...

Embodiment 2

[0033] A 100-ton electric furnace is used to make steel through continuous casting to produce a billet, and a solid core wire with a diameter of 1.6mm is produced through rolling, wire drawing, copper plating and other processes. The main chemical composition (weight percent) of the welding wire is: C0.07, Si0.55, Mn1.0, P0.010, S0.008, Ni4.6, Mo0.35, N0.0035, Zr0.04, Ti0. 12, B0.006, and the balance of iron and unavoidable impurities.

[0034] The parameters of the electroslag welding process are shown in Table 1. Vertical butt joint tests were carried out on ship plates with thickness specifications of 60mm and 80mm respectively. The chemical composition and mechanical properties of the steel plate are the same as in Example 1.

[0035] After welding, the electroslag welded joints were sampled for transverse tensile test and impact test of weld metal. The transverse tensile properties and impact properties are shown in Table 2.

Embodiment 3

[0037]A 100-ton electric furnace is used to make steel through continuous casting to produce a billet, and a solid core wire with a diameter of 1.6mm is produced through rolling, wire drawing, copper plating and other processes. The main chemical composition (weight percent) of the welding wire is: C0.05, Si0.45, Mn0.75, P0.009, S0.005, Ni3.5, Mo0.55, N0.0042, Zr0.06, Ti0. 22, B0.008, and the balance of iron and unavoidable impurities.

[0038] The parameters of the electroslag welding process are shown in Table 1. Vertical butt joint tests were carried out on ship plates with thickness specifications of 60mm and 80mm respectively. The chemical composition and mechanical properties of the steel plate are the same as in Example 1.

[0039] After welding, the electroslag welded joints were sampled for transverse tensile test and impact test of weld metal. The transverse tensile properties and impact properties are shown in Table 2.

[0040] It can be seen from Table 2 that the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact absorption energy | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com