Wastewater treatment pool

A sewage treatment pool and pool body technology, which is applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high cost of flow booster, leakage short circuit, and many impurities. Achieve the effect of reducing construction and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

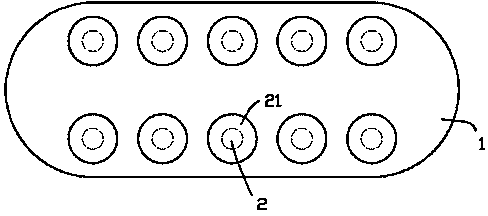

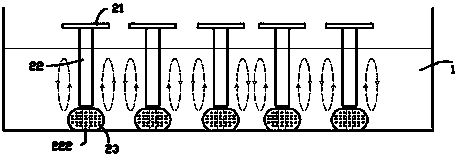

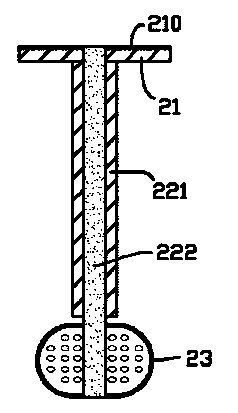

[0021] exist Figure 1-Figure 3 In the shown embodiment, the sewage treatment tank includes a pool body 1, and an array of convection columns 2 is uniformly arranged in the pool body; the convection column 2 includes a cover plate 21 and a column 22, the cover plate 21 is exposed to the water surface, and the cover plate 21 is made of concrete and metal sheet, and its upper surface 210 is a dark metal sheet; the mandrel 222 of the column 22 is made of metal, and the top of the mandrel 222 is connected to the upper surface 210 of the cover plate 21 , the bottom is connected to the pool bottom; the mandrel 222 is exposed near the bottom of the pool, and the rest is covered by the insulation layer 221 made of concrete.

[0022] In order to achieve a good heat conduction effect, the mandrel 222 is made of aluminum pillars or copper pillars.

[0023] The end near the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com