Preparation method of small size and high brightness lanthanum phosphate activated by cerium and terbium, green phosphor

A technology of lanthanum cerium terbium phosphate and green phosphors, applied in chemical instruments and methods, luminescent materials, sustainable manufacturing/processing, etc., can solve the problems of high synthesis temperature, large product particle size, uneven distribution, etc., and achieves the preparation method. Simple, uniform powder particle size, good luminous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

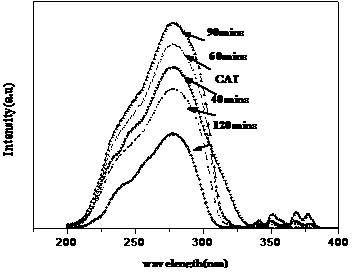

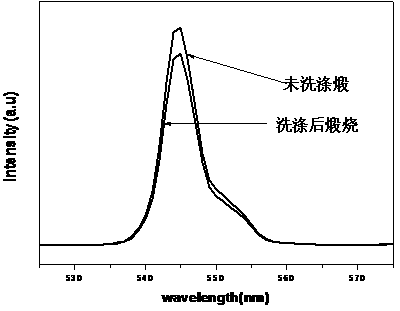

[0030] Embodiment 1: choose the above LaCl of analytical purity 3 ·6H 2 O, CeCl 3 .6H 2 O,TbCl 3 .6H 2 O is the raw material, according to the chemical composition formula La x Ce y Tb 1-x-y PO 4 Accurately weigh the corresponding raw materials for the required molar ratio; select analytically pure (NH 4 ) 2 HPO 4 , weigh diammonium hydrogen phosphate according to phosphate: rare earth = 1.05:1; after mixing them evenly, grind them in the agate grinder for 40 minutes, then dry the product obtained by ball milling in an oven to obtain the precursor, and then in the precursor Add 2% co-solvent Li 2 CO 3 , and finally place the precursor in a reduction furnace for calcination at 1100°C for 3 hours to obtain the product. Its excitation spectrum is shown in figure 1 , XRD diagram see Figure 4 .

Embodiment 2

[0031] Embodiment 2: choose the above LaCl of analytical purity 3 ·6H 2 O, CeCl 3 .6H 2 O,TbCl 3 .6H 2 O is the raw material, according to the chemical composition formula La x Ce y Tb 1-x-y PO 4 Accurately weigh the corresponding raw materials for the required molar ratio; select analytically pure (NH 4 ) 2 HPO 4 , according to phosphate: rare earth = 1.05:1, weigh diammonium hydrogen phosphate; mix them evenly, grind them in agate grinding for 60 minutes, then dry the product obtained by ball milling in an oven to obtain a precursor, and then put it in the precursor Add 2% additive Li 2 CO 3 , and finally place the precursor in a reduction furnace for calcination at 1100°C for 3 hours to obtain the product. Its excitation spectrum is shown in figure 1 , XRD diagram see Figure 4 .

Embodiment 3

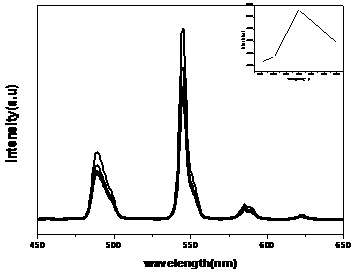

[0032] Embodiment 3: Adopt the same method of embodiment 1, prolong grinding time to 90 minutes, its excitation spectrogram sees figure 1 , XRD diagram see Figure 4 , the emission spectrum see figure 2 , SEM image see Figure 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com