Preparation method of photonic crystal with inverse opal structure

An anti-opal structure and photonic crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve the problems that colloids are difficult to fill gaps, opal structures are easy to fall off and destroy, and consume a lot of manpower, material resources and financial resources. , to achieve the effect of low cost, simple method and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

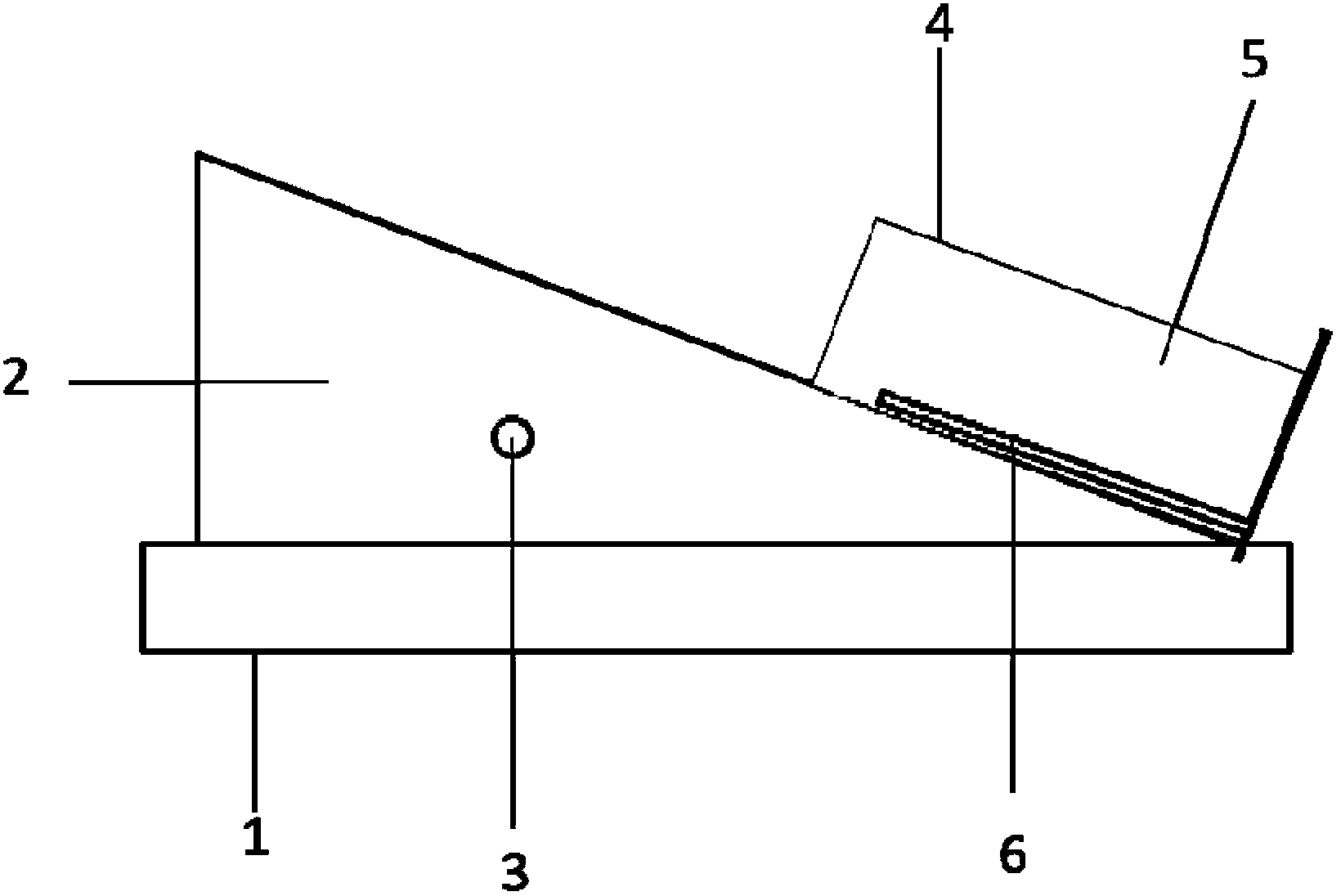

Method used

Image

Examples

Embodiment

[0034] Take 0.1 ml of 10% polystyrene microsphere suspoemulsion (weight percent, particle size: 330nm) and 0.05 ml of 10% TEOS aqueous solution (weight percent, expressed as SiO 2 Measure) into a 4ml cuvette, and add three milliliters of mill-Q water to the above cuvette, ultrasonically disperse for 10 minutes, and mix the above solution evenly. Then put a piece of clean glass substrate vertically into the above-mentioned cuvette. Put the cuvette on the heating stage, under the condition of 75 ℃, polystyrene microsphere template and SiO 2 The colloidal matrix was assembled and grown together on the glass substrate, kept warm for 48 hours, and taken out to obtain polystyrene microspheres and SiO 2 Colloidal composite structure. Put the above composite structure on a high-temperature heating table, heat it in air at 375 °C for 10 hours, and then take it out, thus obtaining high-quality, defect-free SiO 2 Inverse opal structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com