Linear double-acting thermo-acoustic power generation system

A power generation system, linear technology, applied in the direction of machines/engines, mechanical equipment, mechanisms that generate mechanical power, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

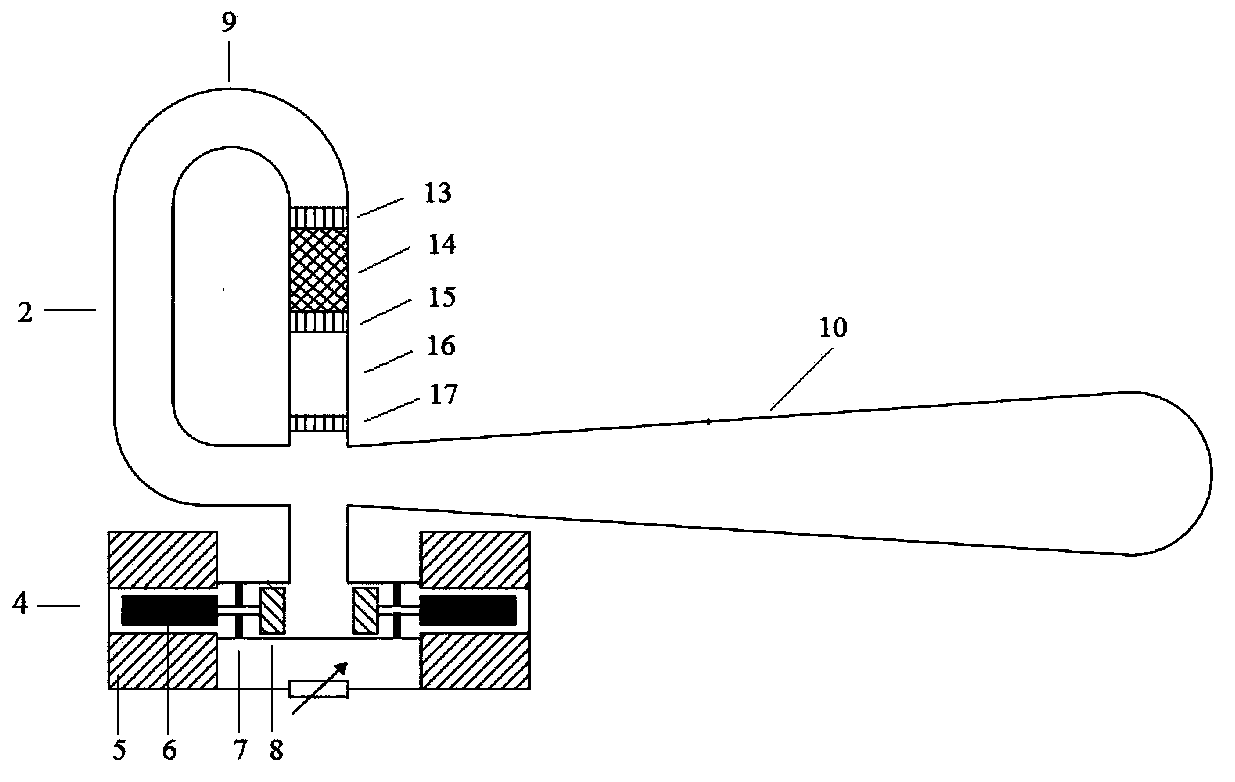

[0073] Figure 4 It is a schematic structural diagram of a linear double-acting thermoacoustic power generation system (Example 1) of the present invention. like Figure 4 As shown, the linear double-acting thermoacoustic power generation system of the present embodiment 1 consists of the first thermoacoustic engine (also known as the first thermoacoustic converter) connected in series between the linear compressor 1 and the linear generator 4 device) 2-1, a linear double-acting generator 3 and a second thermoacoustic engine (also known as a second thermoacoustic converter) 2-2;

[0074] The linear compressor 1 is located at the starting end of the system, which consists of a first compression piston 8, a compressor mover 6 connected to the first compression piston 8, a first leaf spring 7 for fixing the compressor mover 6 and Composed of a compressor stator coil 5 wound around the periphery of the compressor mover 6;

[0075] Both the first thermoacoustic engine 2-1 and th...

Embodiment 2

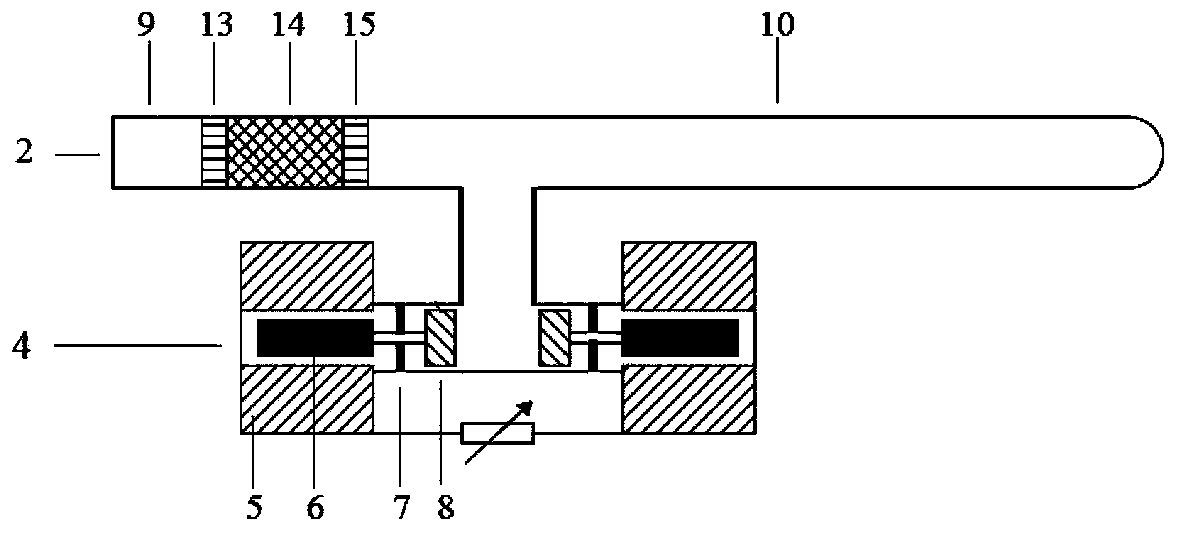

[0082] Figure 5 It is a schematic structural diagram of a linear double-acting Stirling power generation system (Example 2) of the present invention. like Figure 5 As shown, the linear double-acting Stirling power generation system of the present embodiment 2 consists of a linear compressor 1 sequentially connected in series between the linear compressor 1 and the linear generator 4, the first Stirling engine 2 -1. The linear double-acting generator 3, the second Stirling engine 2-2 and the linear generator 4 are composed.

[0083] The linear compressor 1 works at the beginning of the system, and the linear generator 4 works at the end of the system; the linear compressor 1 of this embodiment has the same structure as the linear compressor 1 of Embodiment 1; The linear generator 4 and the linear double-acting generator 3 are slightly different from those in Embodiment 1. The difference is that the linear generator 4 and the linear double-acting generator are used to genera...

Embodiment 3

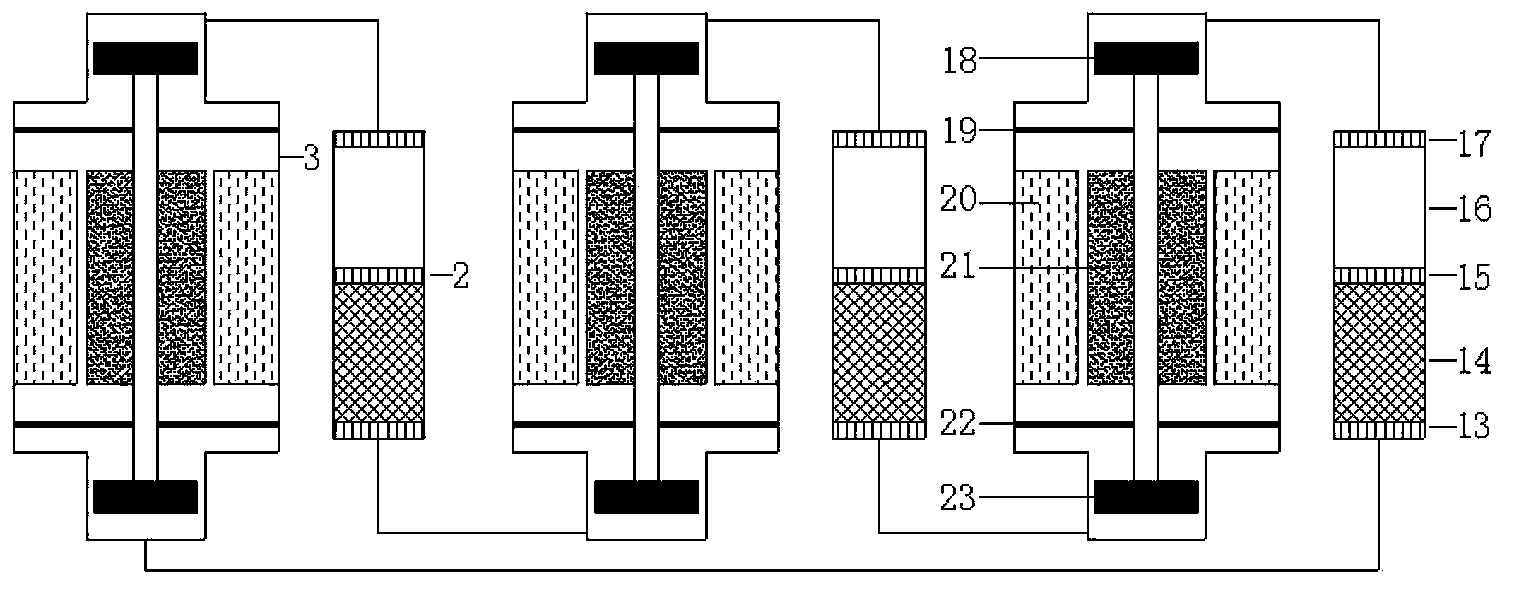

[0086] Figure 6 It is a structural schematic diagram of a novel linear double-acting thermoacoustic generator system (Example 3) of the present invention. like Figure 6 As shown, the linear double-acting thermoacoustic power generation system of Embodiment 3 consists of the first thermoacoustic engine 2-1, the first linear The double-acting generator 3-1 is composed of the second thermoacoustic engine 2-2, the second linear double-acting generator 3-2 and the third thermoacoustic engine 2-3.

[0087] The linear compressor 1 works at the beginning of the system, and the linear generator 4 works at the end of the system; the linear compressor 1 of this embodiment has the same structure as the linear compressor 1 of Embodiment 1; Linear generator 4 is identical in structure with the linear generator 4 of embodiment 1;

[0088] The first thermoacoustic engine 2-1, the second thermoacoustic engine 2-2 and the third thermoacoustic engine 2-3 of this embodiment are all composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com