4-Amino-2-trifluoromethylphenylretinoate self-microemulsion and preparation method thereof

A technology of trifluoromethyl phenyl retinoic acid ester and self-microemulsion, which is applied in the field of self-microemulsion, can solve the problems of water loss, swelling and softening of capsule shell, influence of preparation stability, storage temperature change, etc., and achieves change in flow rate. The effect of improving solubility, improving solubility, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

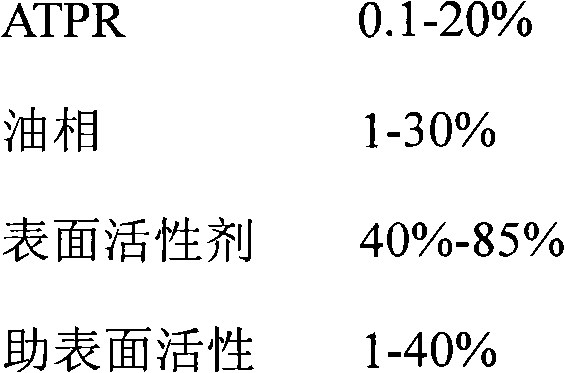

[0028] ATPR self-microemulsion consists of the following components by weight:

[0029] Table 1 ATPR self-microemulsion prescription

[0030]

[0031] Mix the surfactant and co-surfactant evenly according to the above prescription, then mix with the oil phase for 30-40 minutes, add the prescribed amount of ATPR, stir until the drug is completely dissolved, and it is obtained from the microemulsion. Dilute with 100 times of distilled water, and the self-emulsification process is completed in 1 minute. After emulsification, the average particle size of the emulsion droplets is measured by a Malvern nanometer particle size analyzer, and the average particle size is between 10-200nm.

Embodiment 2

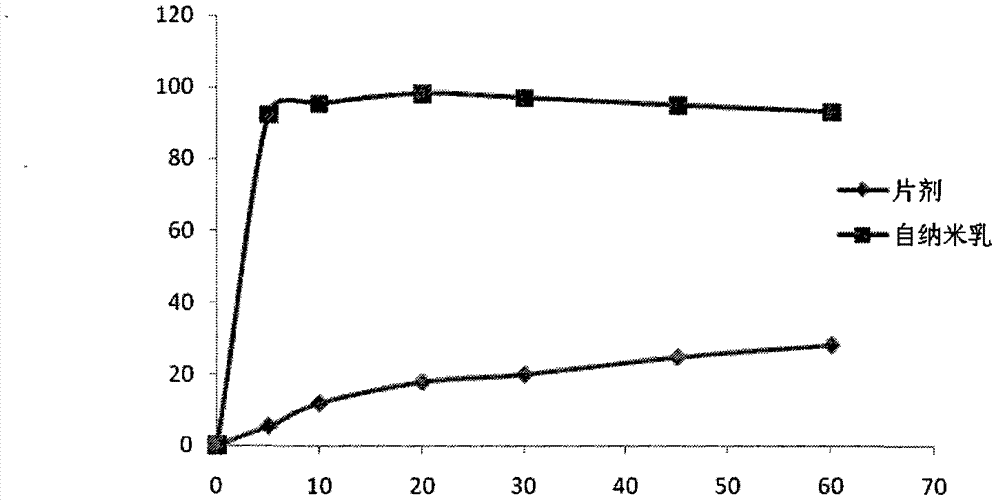

[0033] Prepare the self-microemulsion according to prescription 3, dilute it with 100 times distilled water, and complete the self-emulsification process in 1 minute. It can be dissolved quickly in the medium, and about 90% can be dissolved in 5 minutes, while only about 10% can be dissolved in 5 minutes for ordinary tablets. See the test results figure 1 .

Embodiment 3

[0035] Weigh the raw materials according to prescription 3, mix them for 40 minutes, make them fully dissolve, and prepare the liquid self-microemulsion. Add the adsorbent prescribed in Table 2 below, stir evenly, and pack into hard capsules. In October, March, and June, no obvious oil leakage and softening of the capsule shell were found in the stability inspection.

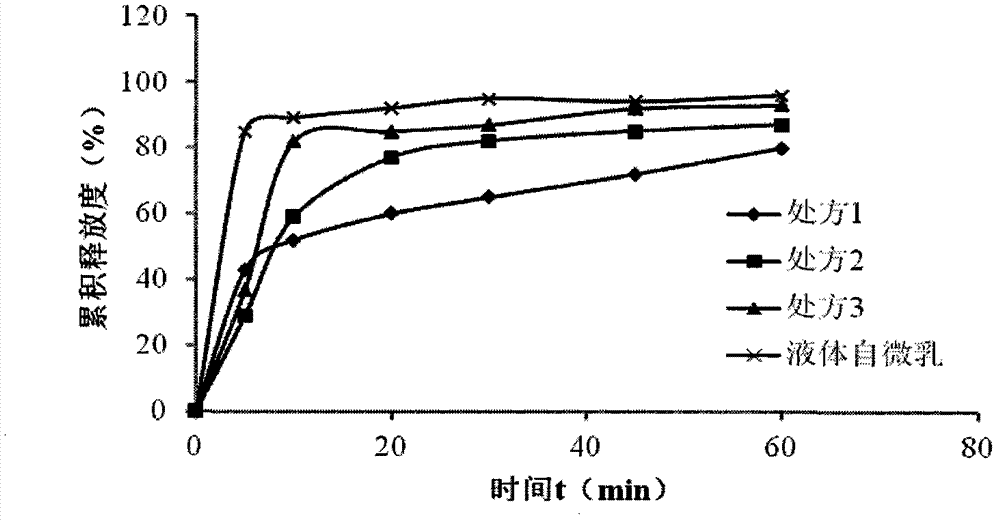

[0036] Get 6 capsules of each prescription and carry out dissolution test, dissolution medium is 1000ml of 0.5% sodium lauryl sulfate solution that 25% isopropanol is made, and rotating speed is 100rpm, temperature: (37 ± 0.5) ℃. Sampling 5ml at 5, 10, 20, 30, 45, 60min respectively. After treatment, the dissolution rate of ATPR was detected by high performance liquid chromatography. The HPLC chromatographic conditions are: chromatographic column: Dalian Elite Hypersil ODS column (4.6mm×250mm, 5μm); mobile phase: methanol-water (92:8); flow rate: 1.0ml / min; detection wavelength: 367nm; column temperature: 30°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com