Disc-type continuous pasty material film dryer

A material film, paste paste technology, applied in the field of disc type film continuous dryer, can solve the problems of low thermal conductivity of paste paste material, affecting drying of paste paste material, large latent heat of water vaporization, etc. Small area, ideal effect, even drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

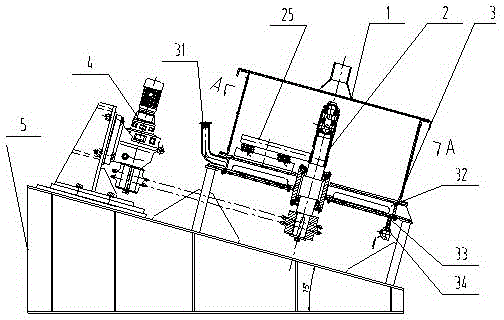

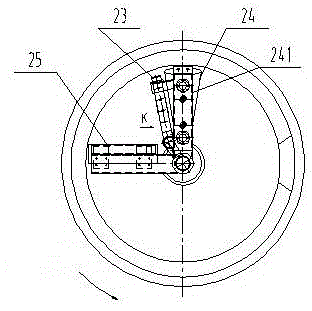

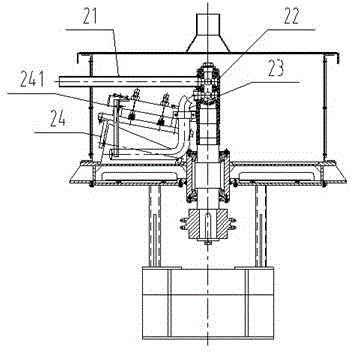

[0022] In order to achieve the above object, the equipment of the present invention is composed of: its main body is composed of an outer cover 1, a spindle system 2, a drying disc 3, a driving system 4, and a support 5. Among them, the main shaft system includes a feed pipe 21, a cloth pipe 23, a pressure roller 24 and a scraper 25; the drying disc 3 is a cavity structure, which is filled with heat-conducting oil; the driving device drives the main shaft system to rotate through a sprocket and a chain; The equipment is installed obliquely through the bracket 5, which facilitates the unloading of the pasty material after drying.

[0023] A further feature of the disk-type continuous film dryer for pasty materials of the present invention is that the upper part of the outer cover 1 is provided with a waste collection hole, and the waste gas and water vapor generated during the drying process are collected and processed in time by a fan.

[0024] Further features of the disk-typ...

Embodiment 2

[0027] like figure 1 As shown, the disc type film dryer for pasty material is composed of five parts: outer cover 1, spindle system 2, drying disc 3, drive system 4, and bracket 5.

[0028] The specific implementation of the disc type paste material film dryer is as follows:

[0029] The heat conduction oil is poured into the heat conduction oil cavity 32 from the oil inlet pipe 31, and the heat conduction oil is heated to the specified temperature after the heating sheet 33 is energized; the pasty material enters the feed cavity 22 from the feed pipe 21, and enters the L through the cavity. Type distribution pipe 23, distribution holes are distributed at the lower end of the distribution pipe, with the rotation of the main shaft, the paste-like material is evenly distributed on the drying disc 31, and a pressing roller 24 is arranged behind the distribution pipe, which presses the paste-like material The film is laid flat, and under the heating of the heat-conducting oil, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com