Processing method for raising strength and toughness of TC4-DT titanium alloy sheet materials

A TC4-DT and processing method technology, which is applied in the processing field of improving the strength and toughness of TC4-DT titanium alloy sheets, can solve problems such as unfavorable fracture toughness fatigue crack growth resistance, overall plasticity and toughness improvement, and unfavorable alloy strength, etc. Reduce deformation dead zone, increase crystalline core, no anisotropy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

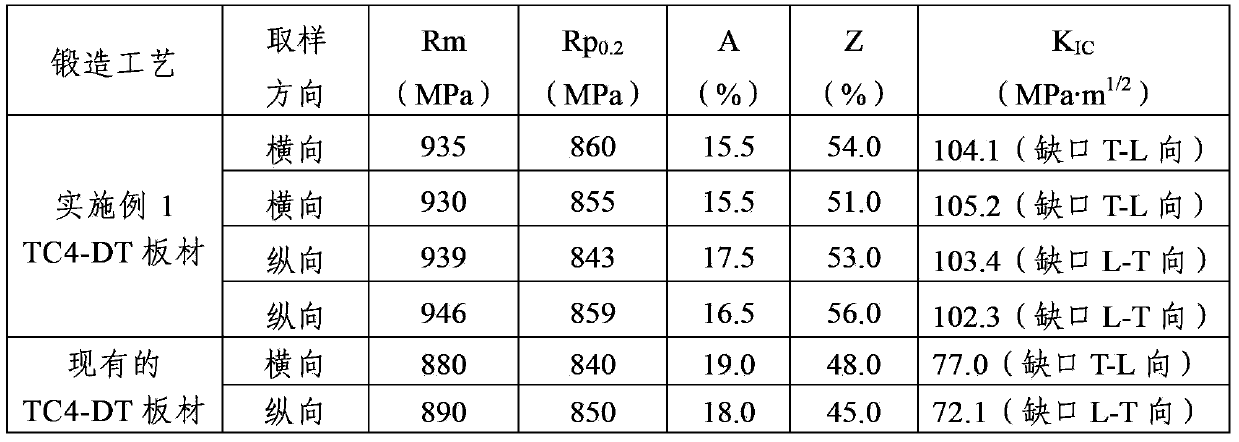

Embodiment 1

[0027] The processing method that present embodiment improves the toughness of TC4-DT titanium alloy plate comprises the following steps:

[0028]Step 1. Use a 1600-ton hydraulic press to carry out blank forging of the TC4-DT titanium alloy ingot, and obtain the first forging billet after water cooling; the cross-sectional shape of the TC4-DT titanium alloy ingot is a circle with a diameter of 460mm; the The billet forging is divided into 1 fire, the forging ratio of the billet forging is 3.1, the final forging temperature of the billet forging is not lower than 900°C, and the TC4-DT titanium alloy ingot is cast before the billet forging Carry out the first-stage heat treatment, the temperature of the first-stage heat treatment is 1100°C to 1150°C, the holding time of the first-stage heat treatment is 276min; the cross-sectional shape of the first forged blank is 230mm in side length the square;

[0029] Step 2. Use a 1600-ton hydraulic press to carry out the first upsetting ...

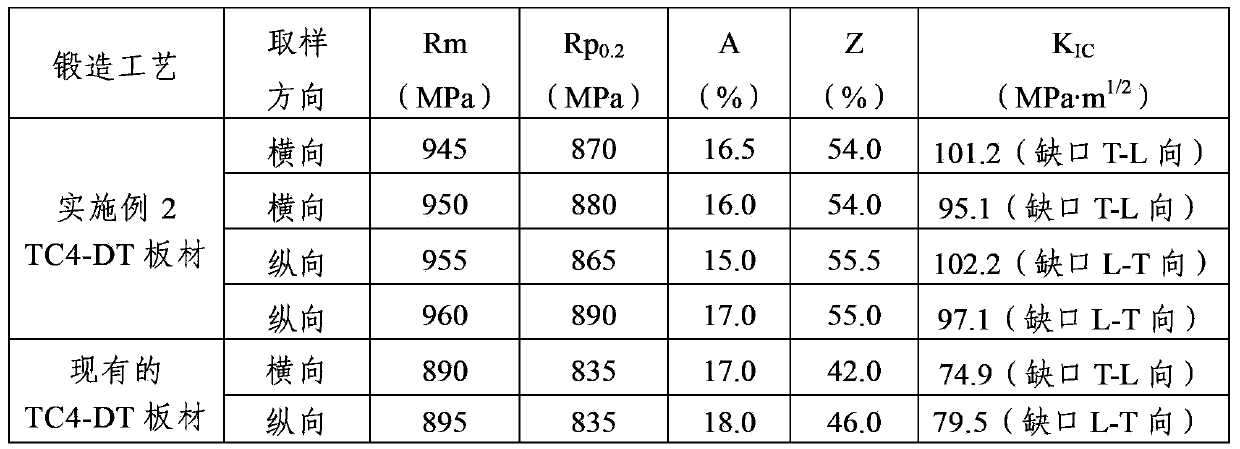

Embodiment 2

[0039] The processing method that present embodiment improves the toughness of TC4-DT titanium alloy plate comprises the following steps:

[0040] Step 1. Use a 2,500-ton hydraulic press to carry out blank forging of the TC4-DT titanium alloy ingot, and obtain the first forging billet after water cooling; the cross-sectional shape of the TC4-DT titanium alloy ingot is a circle with a diameter of 610mm; the The billet forging is divided into 2 fires to complete, the forging ratio of each billet forging is 2.2, the final forging temperature of each billet forging is not lower than 900 ℃, and each fire The TC4-DT titanium alloy ingot is subjected to the first-stage heat treatment, the temperature of the first-stage heat treatment is 1150°C, and the heat preservation time of the first-stage heat treatment is 480min; the cross-sectional shape of the first forged billet is A square with a side length of 250 mm;

[0041] Step 2. Use a 2,500-ton hydraulic press to carry out the first...

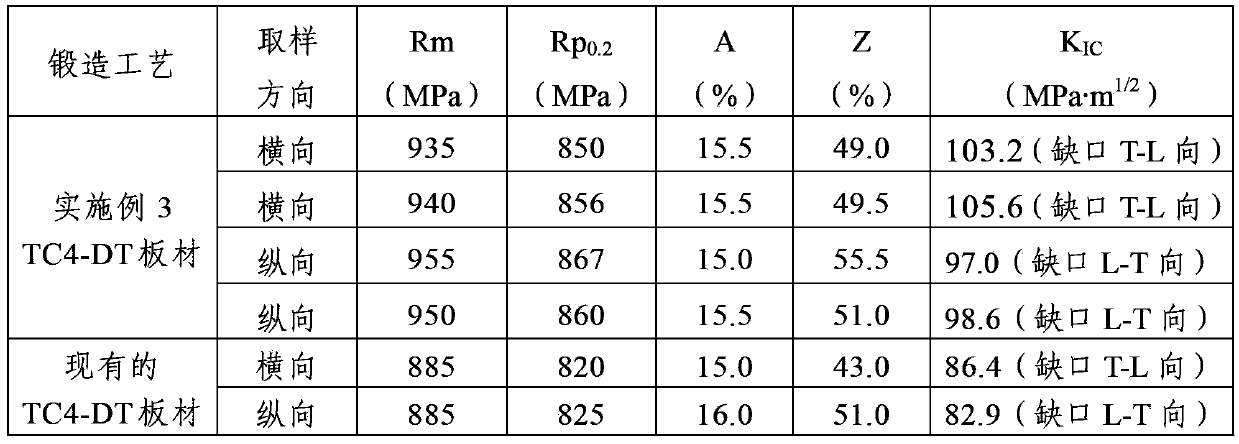

Embodiment 3

[0051] The processing method that present embodiment improves the toughness of TC4-DT titanium alloy plate comprises the following steps:

[0052] Step 1. Use a 2000-ton hydraulic press to carry out blank forging of the TC4-DT titanium alloy ingot, and obtain the first forging billet after water cooling; the cross-sectional shape of the TC4-DT titanium alloy ingot is a circle with a diameter of 560 mm; the The billet forging is divided into 2 fires to complete, the forging ratio of each billet forging is 1.8, the final forging temperature of each billet forging is not lower than 900 ℃, and each fire The TC4-DT titanium alloy ingot is subjected to the first-stage heat treatment, the temperature of the first-stage heat treatment is 1130° C., and the holding time of the first-stage heat treatment is 390 min; the cross-sectional shape of the first forged billet is A square with side length 280;

[0053] Step 2. Use a 2000-ton hydraulic press to carry out the first upsetting forgi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com