Curable epoxy resin composition

A technology for curing epoxy resins and compositions, which is applied in the directions of electrical solid devices, semiconductor/solid device parts, electrical components, etc., can solve the problem that it is difficult to increase the amount of inorganic fillers and the fluidity of curable epoxy resin compositions. and other problems, to achieve the effect of improving flame retardancy, improving reliability, and reducing the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] The preparation method of the curable epoxy resin composition of the present invention is not particularly limited, but the curable epoxy resin composition is prepared by uniformly mixing component (I) and component (II) and other optional components. In the case of using component (III), when component (II) is mixed into a composition in which component (I) and component (III) have been mixed in advance, the dispersibility of component (II) can be improved. In addition, another example is a method in which ingredient (I) and ingredient (IV) are mixed first, and then ingredient (II) and other optional ingredients are uniformly mixed. Other examples of this situation also include a method in which a coupling agent is added to ingredient (I) and ingredient (IV) to prepare an integrated blend, and a method in which In this, the component (IV) is surface-treated with a coupling agent in advance, and then it is mixed with the component (I). In addition, examples of the appar...

example

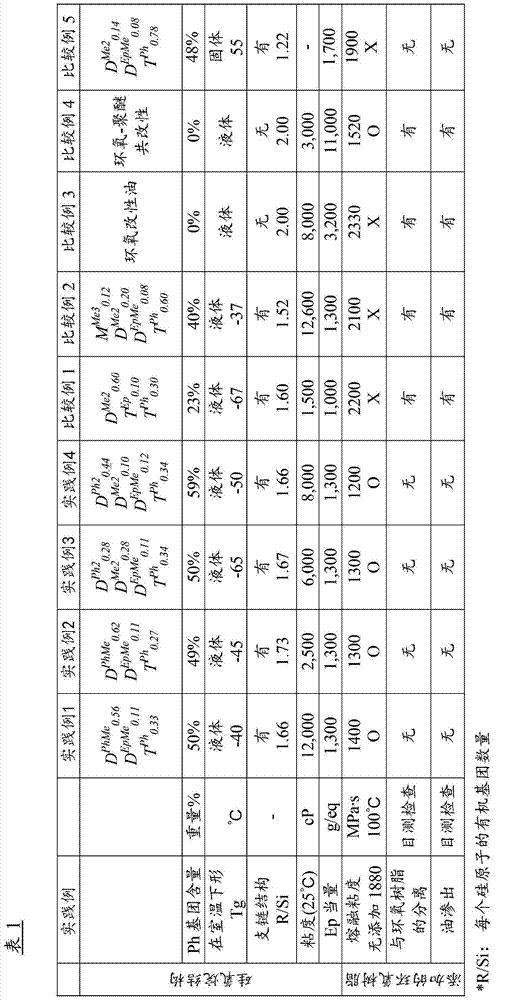

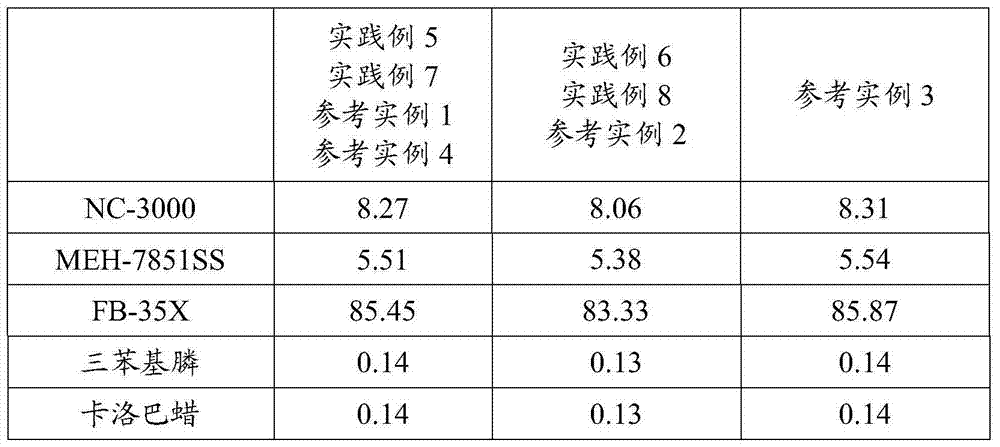

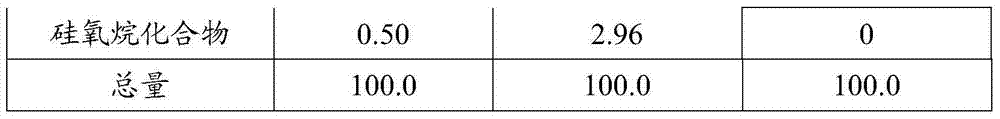

[0095] The present invention is described in detail below based on examples, but the present invention is not limited to the following examples. In the examples, Ph represents a phenyl group, Me represents a methyl group, and Ep represents a 3-glycidoxypropyl group.

[0096] (Viscosity)

[0097] The measurement was performed at 25°C using a Vismetron VG-A1 single-cylinder rotary viscometer (produced by Shibaura System).

[0098] (Weight average molecular weight)

[0099] This value is obtained by standard polystyrene conversion using gel permeation chromatography.

[0100] (Glass transition temperature (Tg))

[0101] A differential calorimeter (DSC: SSC5200 produced by Seiko Instruments Inc. (SII)) was used for measurement.

[0102] (Structural analysis)

[0103] The structure of organopolysiloxane passes 29 Confirmed by Si-NMR spectroscopy (JNM-ECA500 produced by NEC).

[0104] (Epoxy resin equivalent)

[0105] The measurement is performed by the titration method based on JIS K-7236.

[010...

preparation example 1

[0119] The 155.5g of phenyltrichlorosilane hydrolysis / condensation product prepared above, 80.5g of 3-glycidoxypropylmethyldimethoxysilane, 264g of 2,4,6,8-tetramethyl-2,4,6 , 8-tetraphenylcyclotetrasiloxane, 500g toluene and 0.15g cesium hydroxide were put into a 1,000mL flask equipped with a thermometer, Dean-Stark tube and reflux cooling tube. An additional 10.0g of water is added. Then the water and methanol generated when the system was heated were distilled out, and the system was heated and refluxed for another 6 hours. After cooling, 0.08 g of acetic acid was put into the system for neutralization. The generated salt was then filtered, and the filtrate was heated in vacuum to distill off toluene and obtain 475 g of a colorless transparent liquid. The colorless transparent liquid has a weight average molecular weight of 2,500, a glass transition temperature of -40°C and an epoxy equivalent of 1,300. 29 Si-NMR spectrum analysis confirmed that it was a 3-glycidoxypropyl-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com