Preparation method of noble-metal-supported catalyst

A noble metal catalyst and noble metal technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of low catalytic activity, difficulty in ensuring product quality stability, The complexity of the nanocatalyst process and other issues, to achieve a simple, continuous and easy-to-control preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

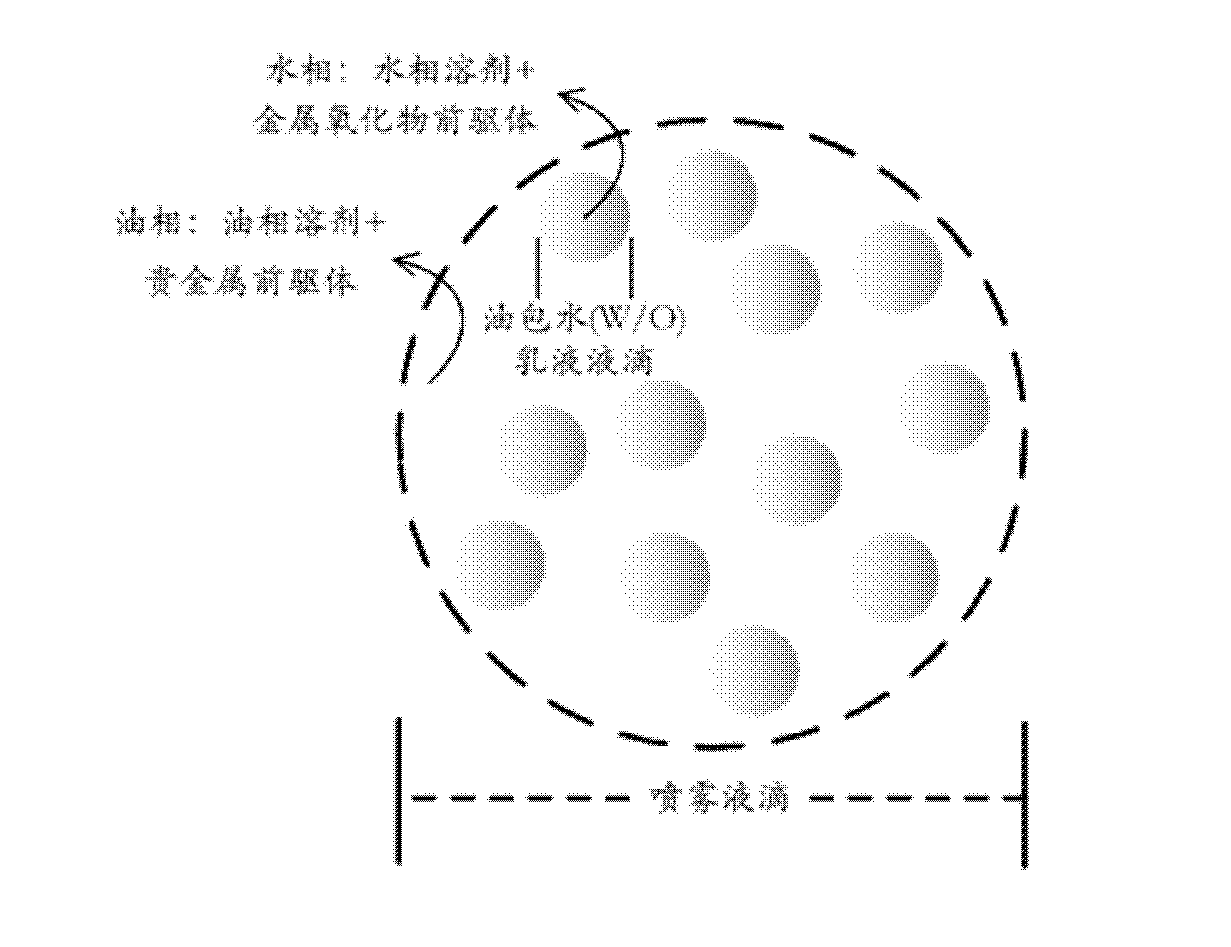

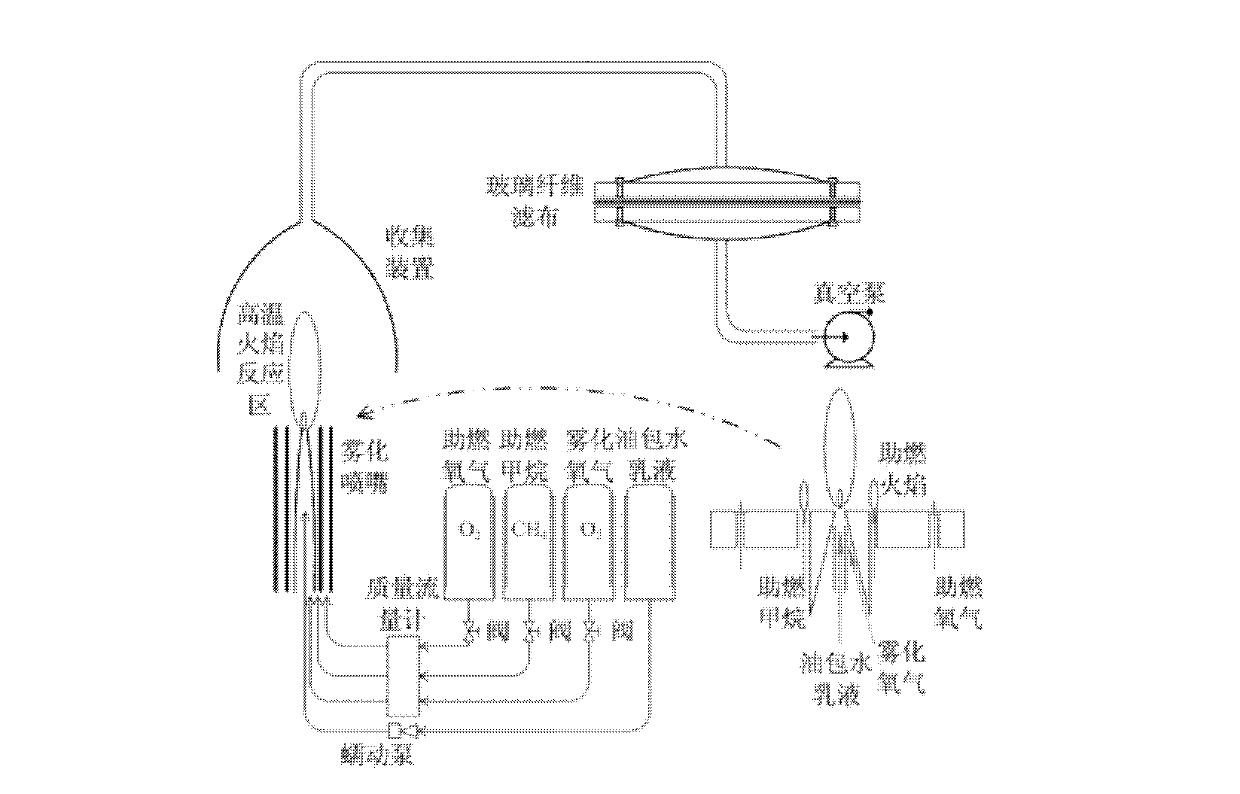

[0030] Prepare 37.5mL containing Ce(NO 3 ) 3 ·6H 2 Aqueous solution of O and 202.5mL containing Pt(acac) 2 xylene oil phase. Among them, Ce(NO 3 ) 3 ·6H 2 The molar concentration of O in the aqueous phase is 1.0mol / L, Pt(acac) 2 The mass fraction of Ce(NO 3 ) 3 ·6H 2 0.2% of O mass. The water phase and the oil phase were ultrasonically mixed for 10 min, and 10 mL of surfactant Span-80 was added at the same time to form a water-in-oil emulsion. The water-in-oil emulsion was passed through a flame spray pyrolysis device ( figure 2 ) after forming spray droplets (spray droplet structure such as figure 1 ) to further prepare loaded noble metal catalyst powder. The flow rate of the emulsion is 9.225mL / min, and the flow rates of combustion-supporting oxygen, combustion-supporting methane and atomizing oxygen are 4.0L / min, 2.4L / min and 4.0L / min, respectively. Use a particle collection device to obtain a powder.

Embodiment 2

[0032] Prepare 50mL containing Ce(NO 3 ) 3 ·6H 2 O, Mn(CH 3 COO) 2 4H 2 O, Al(NO 3 ) 3 , Zn(CH 3 COO) 2 , Zr(NO 3 ) 4 , La(CH 3 COO) 3 The aqueous phase solution and 250.0mL containing Pt(acac) 2 xylene oil phase. Wherein, the total molar concentration of the metal oxide precursor in the aqueous phase is 1.0mol / L, Pt(acac) 2 The mass fraction of is 0.2% of the mass of the metal oxide precursor. The water phase and the oil phase were ultrasonically mixed for 10 min, and 10 mL of surfactant Span-80 was added at the same time to form a water-in-oil emulsion. The emulsion is passed through a flame spray pyrolysis device to prepare a loaded noble metal catalyst powder. The flow rate of the emulsion is 9.225mL / min, and the flow rates of combustion-supporting oxygen, combustion-supporting methane and atomizing oxygen are 4.0L / min, 2.4L / min and 4.0L / min, respectively. Use a particle collection device to obtain a powder.

Embodiment 3

[0034] Prepare 50mL containing Ce(NO 3 ) 3 ·6H 2 Aqueous solution of O and 250mL containing Pt(acac) 2 toluene oil phase. Among them, Ce(NO 3 ) 3 ·6H 2 The molar concentration of O in the aqueous phase is 1.0mol / L, Pt(acac) 2 The mass fraction of Ce(NO 3 ) 3 ·6H 2 0.5% of O mass. The water phase and the oil phase were ultrasonically mixed for 10 min, and 10 mL of surfactants Span-80 and Triton X-100 (volume ratio 1:1) were added at the same time to form a water-in-oil emulsion. The water-in-oil emulsion is passed through the flame spray pyrolysis device to prepare the supported noble metal catalyst powder. The flow rate of the emulsion is 9.225mL / min, and the flow rates of combustion-supporting oxygen, combustion-supporting methane and atomizing oxygen are 4.0L / min, 2.4L / min and 4.0L / min, respectively. Use a particle collection device to obtain a powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com