Method for treating nondegradable organic wastewater by oxidation by transition metal catalyst

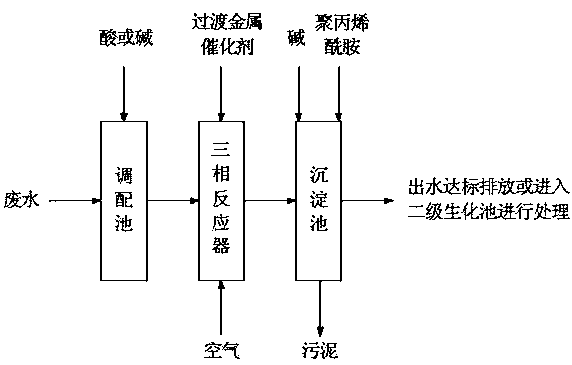

A technology of transition metal catalysis and organic wastewater, which is applied in the direction of oxidized water/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc. It can solve the problems of ecological environment deterioration, hindering industrial development, and easy loss of catalysts, etc., to achieve The effect of thorough reaction, shortened residence time, and reduced sludge production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Wastewater from an organic chemical factory has COD487mg / L, pH=2. Use NaOH to adjust the pH of the wastewater to 3 in the preparation tank, then the wastewater enters the three-phase reactor, and the transition metal catalyst with a mass ratio of 0.01‰ to the wastewater is added to the three-phase reactor, stirred, and gas is introduced at the bottom of the reactor Compressed air with a water ratio of 5, a reaction time of 0.5 hours, and Ca(OH) 2 Adjust the pH of the effluent to 7, add polyacrylamide with a mass ratio of 0.002‰ to the wastewater, and separate the mud and water in the sedimentation tank. The COD of the effluent is 79mg / L, and the removal rate is 83.8%. Transition metal catalysts are composed of Fe and MnO 2 Composite, Fe simple substance and MnO 2 The contents are 95% and 5% respectively, and the particle size is 50 mesh.

Embodiment 2

[0022] Wastewater COD7580mg / L of an organic additive factory, pH=7. Wastewater enters the three-phase reactor, and a transition metal catalyst with a mass ratio of 0.1‰ to the wastewater is added to the three-phase reactor, stirred, and compressed air with an air-water ratio of 20 is introduced at the bottom of the reactor, and the reaction time is 2 hours. After the end, add polyacrylamide with a mass ratio of 0.01‰ to wastewater, and separate mud and water in the sedimentation tank. The effluent COD is 1990mg / L, and the removal rate is 73.7%. The transition metal catalyst is composed of Fe, Mn, Cu, Ag, Ni, and Co. The contents are 60%, 15%, 10%, 5%, 5%, and 5% respectively, and the particle size is 200 mesh.

Embodiment 3

[0024] A pharmaceutical factory wastewater COD2144mg / L, pH=5. Wastewater enters the three-phase reactor, and a transition metal catalyst with a mass ratio of 0.05‰ to the wastewater is added to the three-phase reactor, stirred, and compressed air with an air-water ratio of 15 is introduced at the bottom of the reactor, and the reaction time is 1.8 hours. end with Ca(OH) 2 Adjust the pH of the effluent to 9, add polyacrylamide with a mass ratio of 0.005‰ to the wastewater, and separate the mud and water in the sedimentation tank. The COD of the effluent is 457mg / L, and the removal rate is 78.7%. Transition metal catalysts are simple substances of Fe, Cu, Ag, Ni, Co and MnO 2 Compounded, the contents are 65%, 5%, 5%, 5%, 5% and 15% respectively, and the particle size is 100 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com