Method for treating industrial circulating water

A technology of industrial circulating water and treatment method, which is applied in the field of controlling the growth of microorganisms in the circulating water system and preventing the production of biological slime. Reduced heat transfer efficiency and other issues, to achieve the effect of solving growth and reproduction problems, reducing the dosage of chemicals, and increasing the concentration multiple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

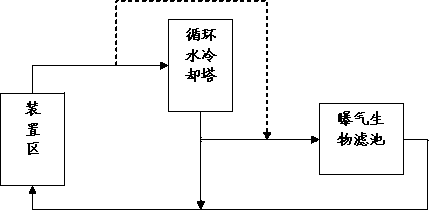

Image

Examples

Embodiment 1

[0025] The circulating water volume of a circulating water plant is 27,000 tons / hour, the COD (chromium method, the same below) of the circulating water influent is 39.2~70mg / L, and the ammonia nitrogen is 2.2~6.9mg / L. Among them, 900 tons / hour of circulating water enters the biological aerated filter (BAF). The operating conditions of the biological aerated filter are: temperature 28°C, pH 7.5, DO 1.5mg / L. Mix the denitrification and denitrification bacteria agent with the activated sludge and add it to the biological aerated filter according to the dosage of MLSS of 1000mg / L. Biofilm formation can be seen after 20 days. At this time, according to the dosage of 100mg / L of MLSS The amount of nitrifying bacteria is added. After treatment, the ammonia nitrogen in the effluent is lower than 2mg / L, and the COD is lower than 5mg / L. The concentration ratio of the circulating water is increased from 4.5 to 5.5. After long-term use, the quality of the circulating water is basically unc...

Embodiment 2

[0027] In the circulating cooling water system of a large petrochemical refinery in China, the total amount of circulating water is 22,000 tons / hour, the control cycle concentration ratio is 2.5, the supplementary water volume is 600 tons / hour, the COD of circulating water is 60.2~79mg / L, and the ammonia nitrogen is 7.2 ~10.9mg / L. The aeration raw filter is used to partially treat the circulating cooling water behind the cooling tower, and the treated circulating water is 1100 tons / hour. First, mix the denitrifying bacteria agent into the activated sludge according to the sludge volume ratio of 0.05%, and then add the mud bacteria mixture to the biological aerated filter. Add the dosage of L to add nitrifying bacteria. The operating conditions of the biological aerated filter are: temperature: 32°C, pH: 7.8, DO: 2.0mg / L. After treatment, the ammonia nitrogen and COD in the effluent are always lower than 5mg / L, which fully meets the water quality requirements of the circulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com