Method for separating and purifying high-purity 3,2'',6''-tri-N-acetyl-gentamicin C1a alkali (P1)

A separation and purification, high-purity technology, applied in chemical instruments and methods, chemical recovery, organic chemistry, etc., can solve the problems of high consumption of water and eluent, high environmental pressure, low production yield, etc., and achieve resin utilization. High, floor space saving, production cycle reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

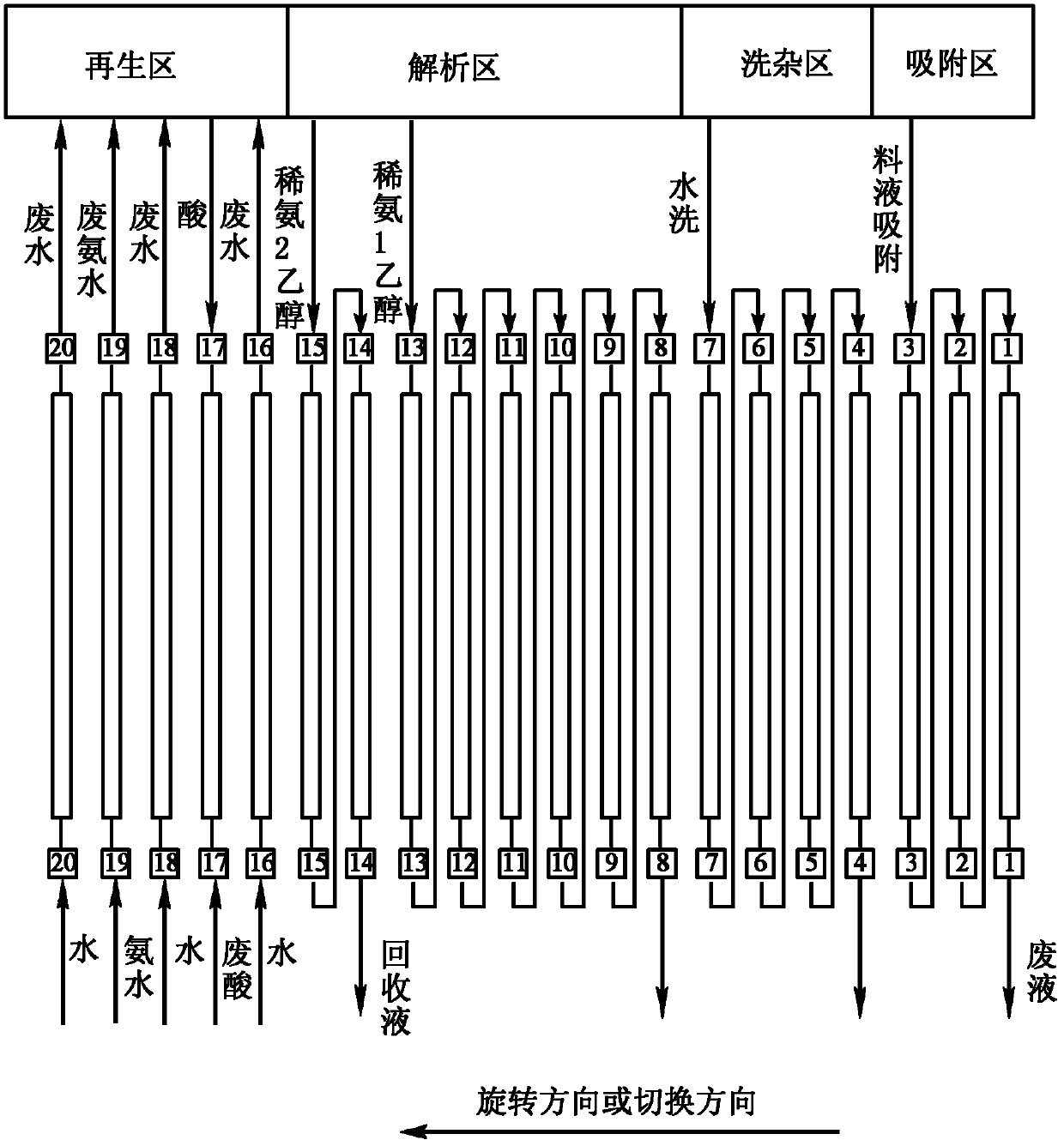

[0050] Combine below figure 1 And the embodiment is described in detail:

[0051] The selected resin of the present invention is a weakly acidic cation exchange resin, the resin is 30 to 80 mesh, and the filling capacity of each resin tank is 0.12m 3 , the size of the resin tank is Φ350×600mm, and the actual filling ratio is 78%. The total size of the system is about 3m×3m×5m (length×width×height).

[0052] Disc transfer type continuous chromatographic separation system separates 3, 2 ", 6 ",-tri-N-acetyl gentamycin C1a base (P1) is divided into the following areas:

[0053] 1) Adsorption area: 1 to 3 units;

[0054] Each unit resin tank in this area is connected in series as a group, controlled by flow rate. The raw material first enters the inlet of No. 3 column, and the liquid flowing out from the outlet of No. 1 column is waste liquid.

[0055] 2) Miscellaneous washing area: units 4 to 7;

[0056] After adsorption, each resin tank needs to be washed with water, locat...

Embodiment 2

[0070] Combine below figure 1 And the embodiment is described in detail:

[0071] The selected resin of the present invention is a weakly acidic cation exchange resin, the resin is 30 to 80 mesh, and the filling capacity of each resin tank is 0.12m 3 , the size of the resin tank is Φ350×600mm, and the actual filling ratio is 78%. The total size of the system is about 3m×3m×5m (length×width×height).

[0072] The simulated moving bed type continuous chromatographic separation system separates 3, 2 ", 6 ",-tri-N-acetyl gentamycin C1a base (P1) is divided into the following areas:

[0073] 1) Adsorption area: 1 to 3 units;

[0074] The feed liquid inlet and waste liquid outlet are located in the adsorption zone. Each unit resin tank in this area is connected in series as a group, controlled by flow rate. The raw material first enters the inlet of No. 3 column, and the liquid flowing out from the outlet of No. 1 column is waste liquid.

[0075] 2) Miscellaneous washing area: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com