Specific papermaking filling and paper containing same

A powder and monomer technology, applied in the field of inorganic non-metallic powder composite materials, can solve the problems of increasing the complexity of the wet end environment and low connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

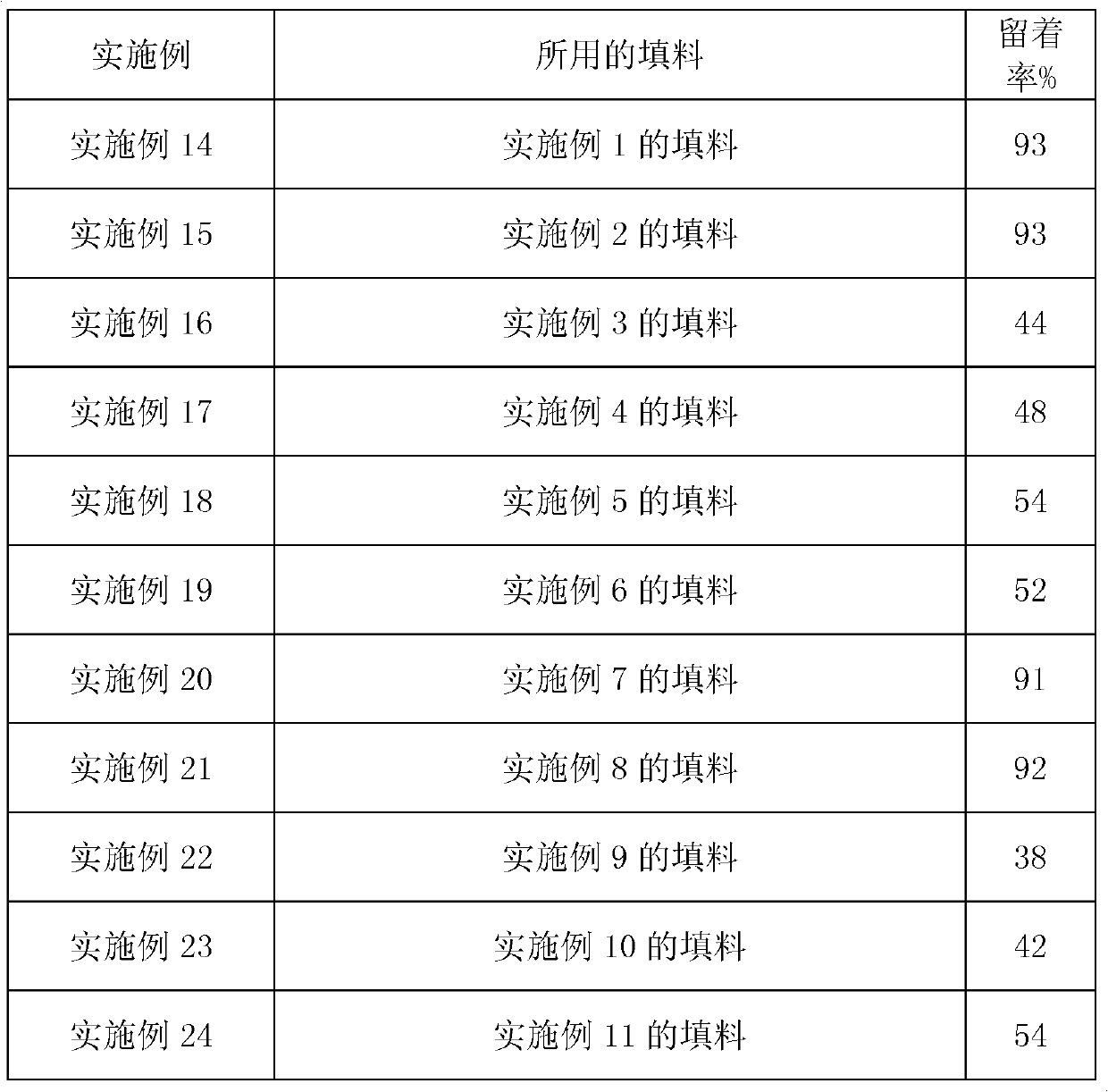

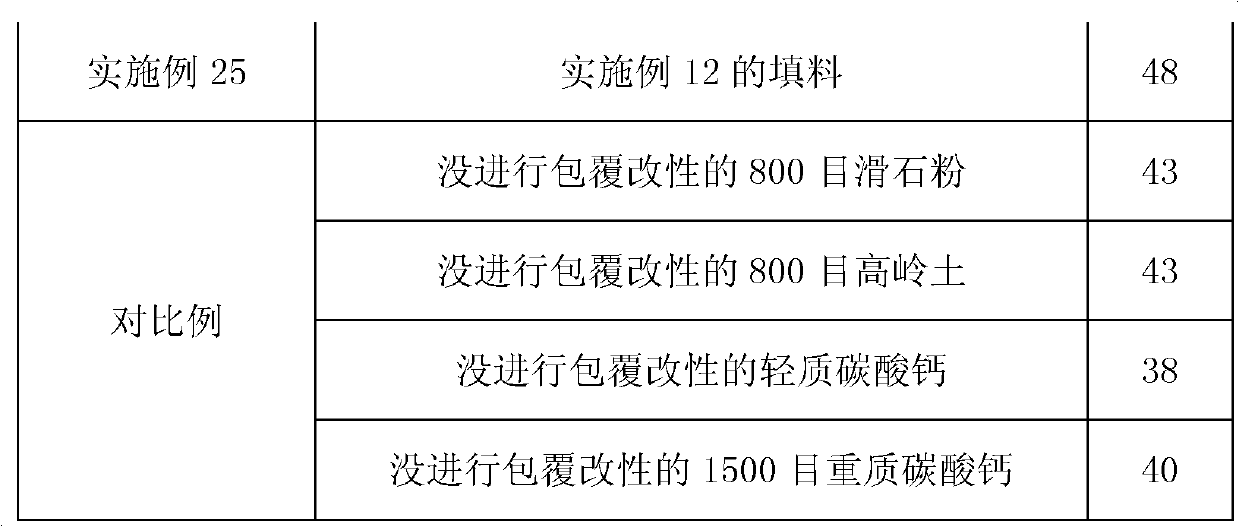

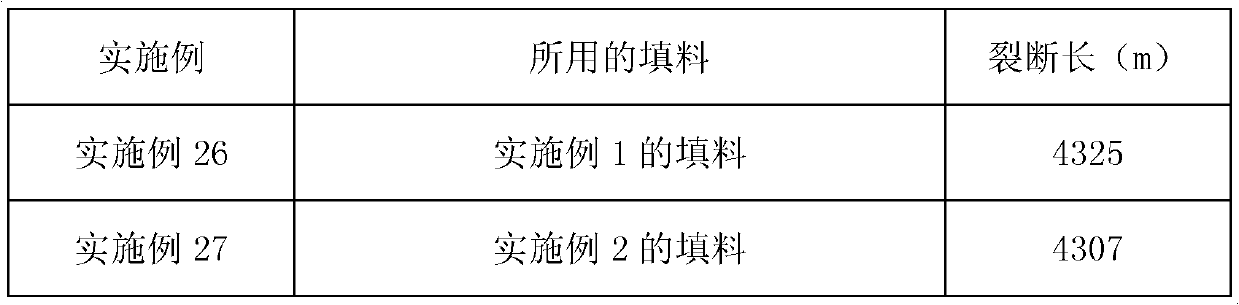

Examples

Embodiment 1

[0036] This example is a production example of the special filler for composite papermaking of the present invention.

[0037] A. Pretreatment: In a 300ml beaker, sequentially add 60g of talc powder with a particle size of 800 mesh, 200g of absolute ethanol, and 0.18g of vinyltriethoxysilane, disperse by ultrasonic oscillation for 1 hour, and then transfer it into the In a water bath and a 300ml three-neck flask with a stirring and reflux condensing device, under the control of the boiling temperature of ethanol, stir and reflux for 60 minutes. After cooling down later, the suspension was subjected to vacuum filtration, and the filter cake was dried at 105° C. until the mass was constant to obtain a pretreated talc powder.

[0038] B. Coating modification: 50g of the above-mentioned pretreated powder, 200g of deionized water, 1.50g of acrylamide, 0.20g of dimethyldiallylammonium chloride, and 0.10g of methylenebisacrylamide And sodium persulfate 0.02g, add in turn into a 300m...

Embodiment 2

[0041] This example is another manufacturing example of the special filler for composite papermaking of the present invention.

[0042] A. Pretreatment: In a 300ml beaker, sequentially add 60g of kaolin powder with a particle size of 800 mesh, 200g of absolute ethanol, and 0.18g of vinyltriethoxysilane, disperse by ultrasonic oscillation for 1 hour, and then transfer it into a temperature-controlled water bath In a 300ml three-necked flask with a stirring and reflux condensing device in a pot, the mixture was stirred and refluxed for 60 minutes at the boiling temperature of ethanol. After cooling down later, the suspension was subjected to vacuum filtration, and the filter cake was dried at 105° C. until the quality was constant, that is, a pretreated kaolin powder was obtained.

[0043] B. Coating modification: 50g of the above-mentioned pretreated powder, 200g of deionized water, 1.50g of acrylamide, 0.20g of dimethyldiallylammonium chloride, and 0.10g of methylenebisacrylam...

Embodiment 3

[0046] This example is another manufacturing example of the special filler for composite papermaking of the present invention.

[0047] A. Pretreatment: In a 300ml beaker, sequentially add 60g of talc powder with a particle size of 800 mesh, 200g of absolute ethanol, and 0.18g of vinyltriethoxysilane, disperse by ultrasonic oscillation for 1 hour, and then transfer it into the In a water bath and a 300ml three-neck flask with a stirring and reflux condensing device, under the control of the boiling temperature of ethanol, stir and reflux for 60 minutes. After cooling down later, the suspension was subjected to vacuum filtration, and the filter cake was dried at 105° C. until the mass was constant to obtain a pretreated talc powder.

[0048] B. Coating modification: 50g of the above-mentioned pretreated powder, 200g of deionized water, 1.5g of acrylic acid, 0.10g of methylenebisacrylamide and 0.015g of sodium persulfate were added in sequence In a water bath and a 300ml three-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com