Cane trash-based composite filler, preparation method thereof and paper comprising composite filler

A technology of composite filler and bagasse, which is applied in the field of papermaking, can solve problems such as unsatisfactory results, and achieve the effects of improving the retention rate of the wire part, the retention rate of toughening, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

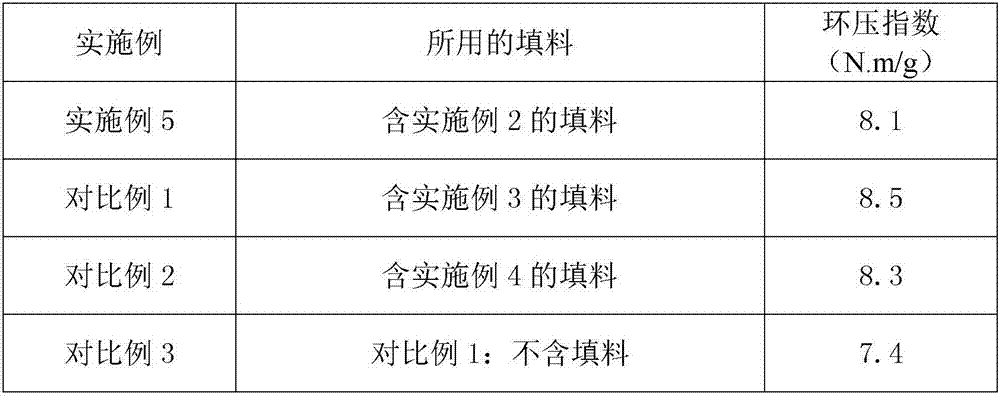

Examples

Embodiment 1

[0035] This example is the manufacturing embodiment of the bagasse grinding of the present invention.

[0036] The air-dried bagasse is crushed with a hammer crusher. Under the action of the air flow in the crushing room, the crushed matter is discharged through a sieve (screen mesh diameter 4mm), and the crushed matter is then classified by the secondary air damper when it is fully opened. The type impact mill crushes the coarsely broken and sieved bagasse, and collects bagasse powder particles smaller than 60 mesh.

Embodiment 2

[0038] This example is a manufacturing example of the bagasse-based composite filler of the present invention.

[0039] A. Coating modification:

[0040] With 50g of the bagasse powder particles of the above-mentioned embodiment 1, 200g of deionized water, 0.001g of EDTA-2Na, 1.50g of acrylamide, 0.20g of dimethyldiallylammonium chloride, and 0.02g of methylenebisacrylamide, Sequentially add to the 300ml there-necked flask which has been placed in a temperature-controlled water bath with a stirring and nitrogen device, stir to form a suspension, then use dilute nitric acid (30%) to adjust the pH value of the reaction system to 3.0-4.0, and then add nitric acid 0.015 g of cerium amine, and then bubbling nitrogen and deoxygenating for 30 minutes, then heating up to 50°C while stirring, stirring and reacting at 48-52°C for 5 hours, and then ending the reaction.

[0041] B. Drying:

[0042] Then, the above-mentioned coated and modified powder suspension was filtered, and then th...

Embodiment 3

[0044] This example is another manufacturing example of the bagasse-based composite filler of the present invention.

[0045] A. Coating modification:

[0046] 50 g of the bagasse powder particles of the above-mentioned embodiment 1, 200 g of deionized water, 0.001 g of sodium ethylenediamine tetramethylene phosphate (EDTMPS), 2.0 g of acrylamide, and 0.20 g of methacryloyloxyethyltrimethylammonium chloride g, 0.015g of methylenebisacrylamide, added to a 300ml three-necked flask which has been placed in a temperature-controlled water bath and equipped with a stirring and nitrogen device, stirred into a suspension, and then added 0.025g of cerium ammonium nitrate and dissolved The mixed solution in 1 ml of 1N nitric acid was then pumped with nitrogen and oxygen for 30 minutes, then the temperature was raised to 40°C while stirring, and the reaction was terminated after stirring at 40-45°C for 6 hours.

[0047] B. Drying:

[0048] Then, the above-mentioned coated and modified ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com