Starch based composite packing as well as preparation method and application thereof

A composite filler and starch-based technology, which is applied in the field of papermaking, can solve the problems of increasing environmental pollution, affecting economy, and low retention rate, and achieves the effects of improving physical strength, reducing costs, and toughening retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

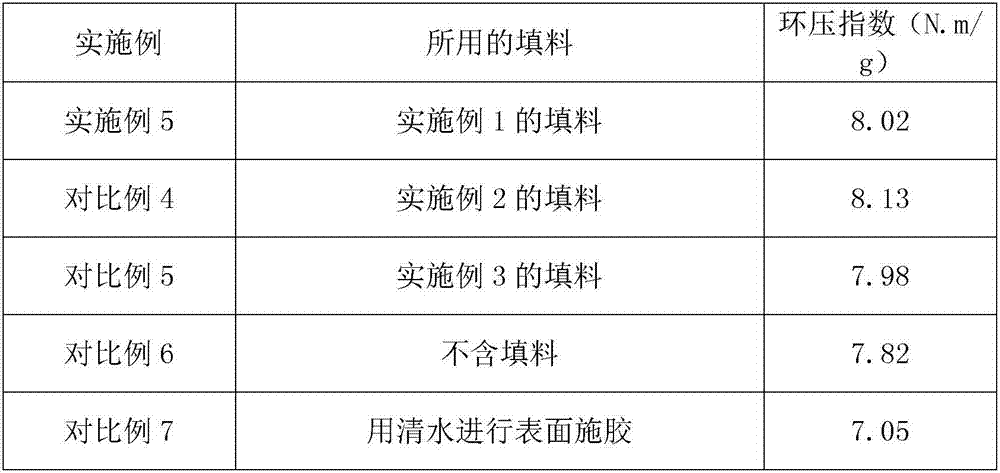

Examples

Embodiment 1

[0032] This example is a manufacturing example of the starch-based composite filler of the present invention.

[0033] A. Coating modification: 50g of raw corn starch, 200g of deionized water, 0.001g of EDTA-2Na, 1.50g of acrylamide, 0.20g of dimethyl diallyl ammonium chloride, and 0.02g of methylenebisacrylamide , add successively in the 300ml there-necked bottle that has been placed in the temperature-controlled water bath and band stirring and nitrogen-passing device, stir into a suspension, then adjust the pH value of the reaction system with dilute nitric acid (30%) to be 3.0~4.0, then Add 0.015 g of cerium ammonium nitrate, and then exhaust nitrogen and oxygen for 30 minutes, then raise the temperature to 50°C while stirring, and finish the reaction after stirring and reacting at 48-52°C for 5 hours.

[0034] B. Drying: Then filter the above-mentioned coated and modified powder suspension, then wash the filter cake with 400g distilled water and filter again, and repeat 8...

Embodiment 2

[0036] This example is another manufacturing example of the starch-based composite filler of the present invention.

[0037] A. Coating modification: 50g of tapioca raw starch, 200g of deionized water, 0.001g of sodium ethylenediaminetetramethylene phosphate (EDTMPS), 2.0g of acrylamide, and methacryloyloxyethyltrimethylammonium chloride 0.20g and 0.015g of methylenebisacrylamide were added in sequence to a 300ml three-neck flask which had been placed in a temperature-controlled water bath and equipped with a stirring and nitrogen device, and stirred to form a suspension, and then added 0.025g of ammonium cerium nitrate and Dissolve the mixed solution in 1 ml of 1N nitric acid, blow nitrogen and deoxygenate for 30 minutes, then raise the temperature to 40°C while stirring, react at 40-45°C for 6 hours, and then end the reaction.

[0038] B. Drying: Then filter the above-mentioned coated and modified powder suspension, then wash the filter cake with 350g distilled water and fil...

Embodiment 3

[0040] This example is another manufacturing example of the starch-based composite filler of the present invention.

[0041] A. Coating modification: 50g of plantain taro raw starch, 200g of deionized water, 0.001g of diethylenetriamine pentacarboxylate (DTPA), 1.5g of acrylamide, 0.1g of acrylic acid, acryloyloxyethyl trimethyl Ammonium chloride 0.12g, methylenebisacrylamide 0.015g, 4-hydroxybutyl vinyl ether 0.02, were added in sequence to a 300ml three-necked flask placed in a temperature-controlled water bath and equipped with a stirring and nitrogen ventilation device, and stirred to form Suspension, then add a mixed solution containing 0.02g of cerium ammonium nitrate dissolved in 1ml of 1.5N nitric acid, and then blow nitrogen and deoxygenate for 30min, then heat up to 38°C while stirring, and react at 35-40°C for 6h End the reaction.

[0042] B. Drying: Then filter the above-mentioned coated and modified powder suspension, then wash the filter cake with 300g distilled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com