A kind of technique of biodiesel transesterification reaction

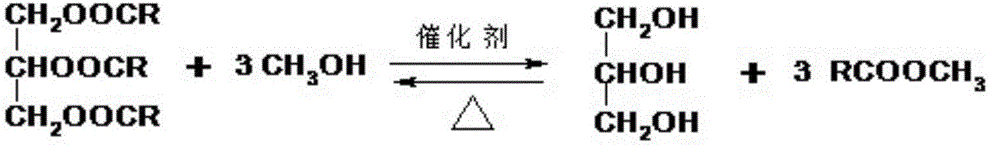

A technology of exchange reaction and diesel ester, which is applied in the field of fatty acid esters, can solve the problems of high energy consumption, low conversion rate, long reaction time, etc., and achieve the effect of full reaction, increased conversion rate and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

[0017] Take 100 kg of esterified waste oil (average molecular weight 900), 6 kg of anhydrous methanol, and 40 grams of sodium hydroxide; feed the waste oil, anhydrous methanol, and sodium hydroxide into the reactor, stir and heat, and the reactor gradually Pressurize to 0.8MPa, then the temperature rises to 150°C, react for 30 minutes, and finally obtain 99.506 kg of biodiesel through distillation.

Embodiment 2)

[0019] Take 100 kg of esterified waste oil (average molecular weight 900), 6 kg of anhydrous methanol, and 40 grams of sodium hydroxide; feed the waste oil, anhydrous methanol, and sodium hydroxide into the reactor, stir and heat, and the reactor gradually Pressurize to 0.85MPa, then the temperature rises to 155°C, react for 30 minutes, then distill and finally obtain 99.602 kg of biodiesel.

Embodiment 3)

[0021] Take 100 kg of esterified waste oil (average molecular weight 900), 6 kg of anhydrous methanol, and 40 grams of sodium hydroxide; feed the waste oil, anhydrous methanol, and sodium hydroxide into the reactor, stir and heat, and the reactor gradually Pressurize to 0.83MPa, then the temperature rises to 155°C, react for 30 minutes, and finally obtain 99.505 kg of biodiesel through distillation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com