Lithium ion battery cathode active material and its preparation method

A negative electrode active material, lithium-ion battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., to achieve the effect of convenient operation, easy operation, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

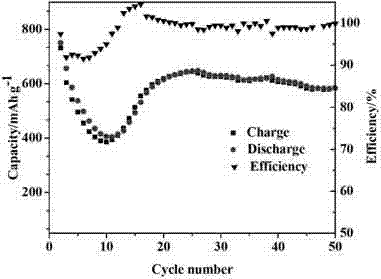

experiment example 1

[0027] Weigh 0.105g terephthalic acid, 0.375g cobalt nitrate hexahydrate (1:2 molar ratio), 30ml DMF, 20ml absolute ethanol and 10ml distilled water (3:2:1 volume ratio) PTFE-lined stainless steel reactor. The reaction kettle was placed in a programmable temperature-controlled oven, and after being kept at 110°C for 2.75 days, the temperature was lowered to room temperature at a rate of 3°C / h, filtered, and dried to obtain 0.182 g of cobalt terephthalate powder.

experiment example 2

[0029] Weigh 0.105g terephthalic acid, 0.375g cobalt nitrate hexahydrate (1:2 molar ratio), 30ml DMF, 20ml absolute ethanol and 10ml distilled water (1:1:1 volume ratio) PTFE-lined stainless steel reactor. The reaction kettle was placed in a programmable temperature-controlled oven, and after being kept at 130°C for 2.75 days, the temperature was lowered to room temperature at a rate of 3°C / h, filtered, and dried to obtain 0.181 g of cobalt terephthalate powder.

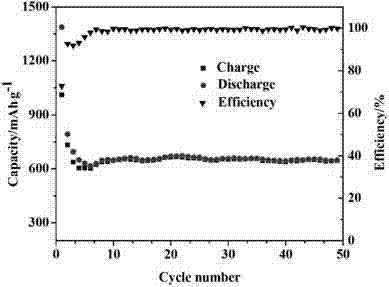

experiment example 3

[0031] Weigh 0.105g of terephthalic acid, 0.375g of cobalt nitrate hexahydrate (molar ratio 1:2), 20ml of DMF, 20ml of absolute ethanol and 20ml of distilled water (volume ratio of 1:1:1) in a 100mL belt at room temperature PTFE-lined stainless steel reactor. The reaction kettle was placed in a programmable temperature-controlled oven, and after being kept at 110°C for 2.75 days, the temperature was lowered to room temperature at a rate of 3°C / h, filtered, and dried to obtain 0.223 g of cobalt terephthalate powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com