Preparation method for organic material decomposition agent

A technology of organic materials and decomposing agents, applied in the direction of organic fertilizers, etc., can solve the problems of poor adaptability of strains, low degree of industrialization, and unstable effects, and achieve the effects of stimulating growth and development, high spore count content, and advanced and scientific preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

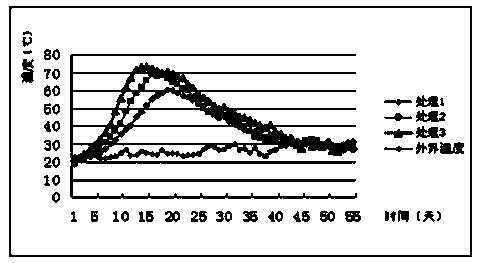

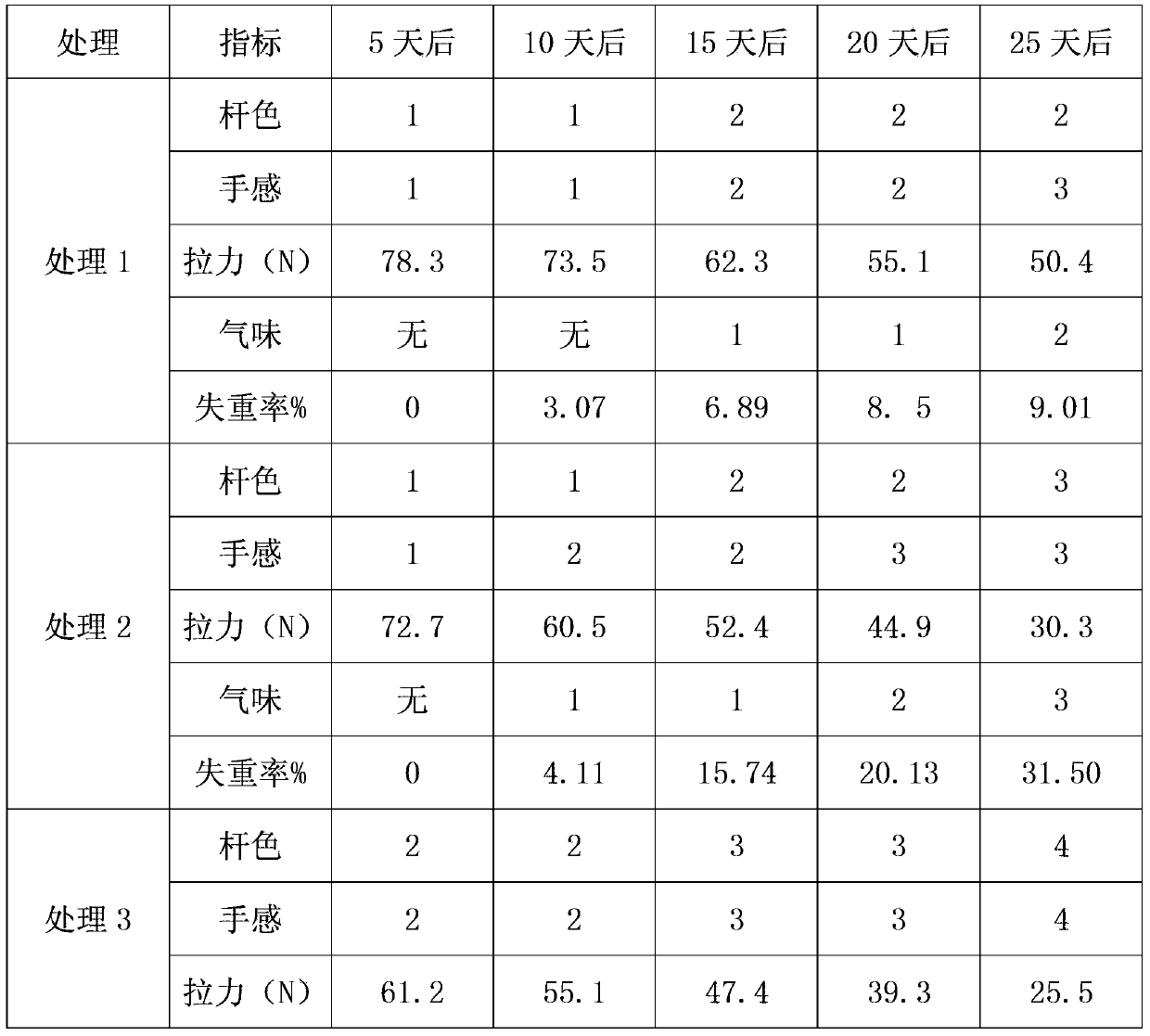

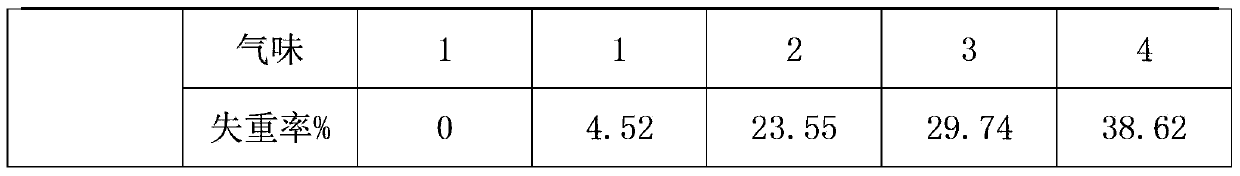

Image

Examples

Embodiment

[0037] Preparation of Bacillus subtilis:

[0038] (1) Inoculate the prepared eggplant-shaped bottle with the Bacillus subtilis strains preserved in the laboratory in a sterile environment, cultivate it at 31-32°C for 31-35 hours, check for no bacteria and keep it as a fermenter vaccination;

[0039] (2) Preparation of fermentation medium: The medium materials in the fermentation tank are prepared according to the ratio of 20g of glucose, 15g of peptone, 5g of sodium chloride, 0.5g of beef extract and 20g of agar per liter of water, so that they are dissolved in water and sent to into the fermenter;

[0040] (3) Inoculation: Inoculate several bacteria-free eggplant-shaped bottles obtained in the process of step (1), and inoculate 3 eggplant-shaped bottle strains per cubic medium, and insert them into the sterilized fermenter through aseptic operation middle;

[0041] (4) Fermentation culture: Stir and cultivate the fermenter at a temperature of 29-34°C and a rotation speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com