Method for filling surface molecular layer defects of wide bandgap semiconductor adopting nano structure

A wide-bandgap semiconductor and nanostructure technology, applied in electrolytic capacitors, photovoltaic power generation, electrical components, etc., can solve problems such as low charge transfer recombination energy, low charge collection efficiency, and low activation energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

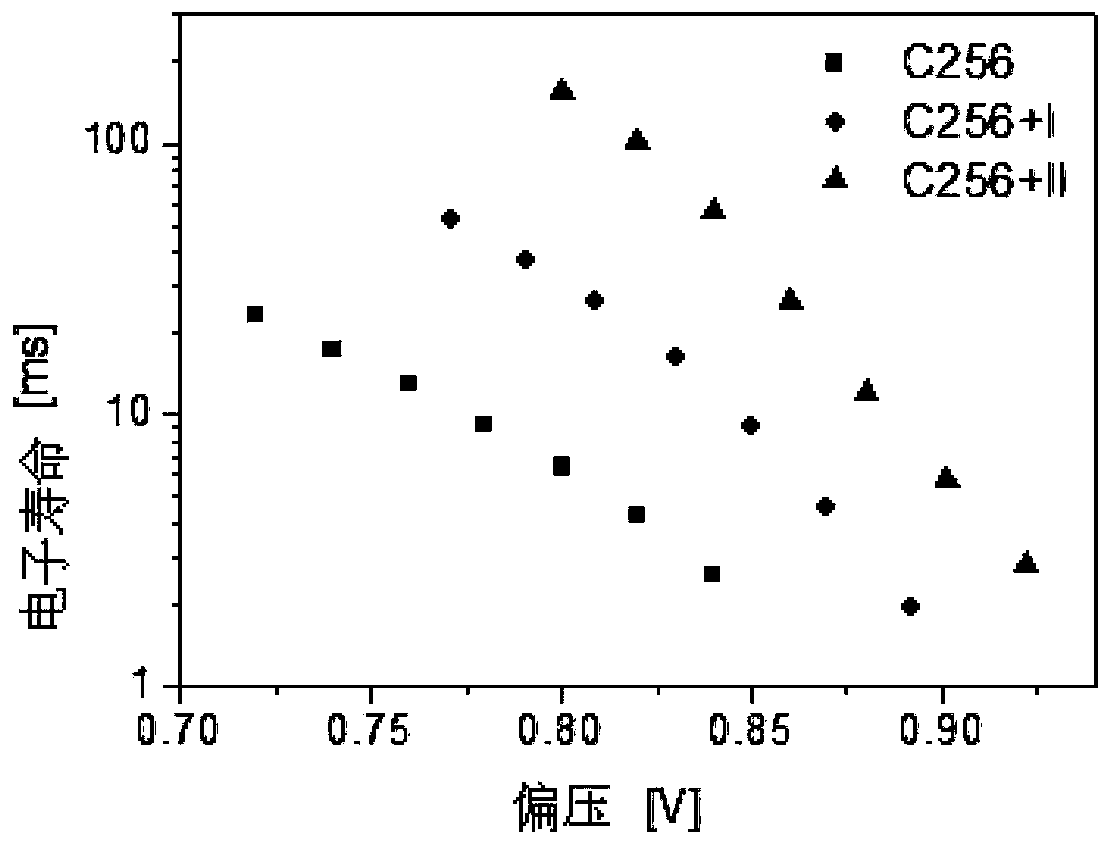

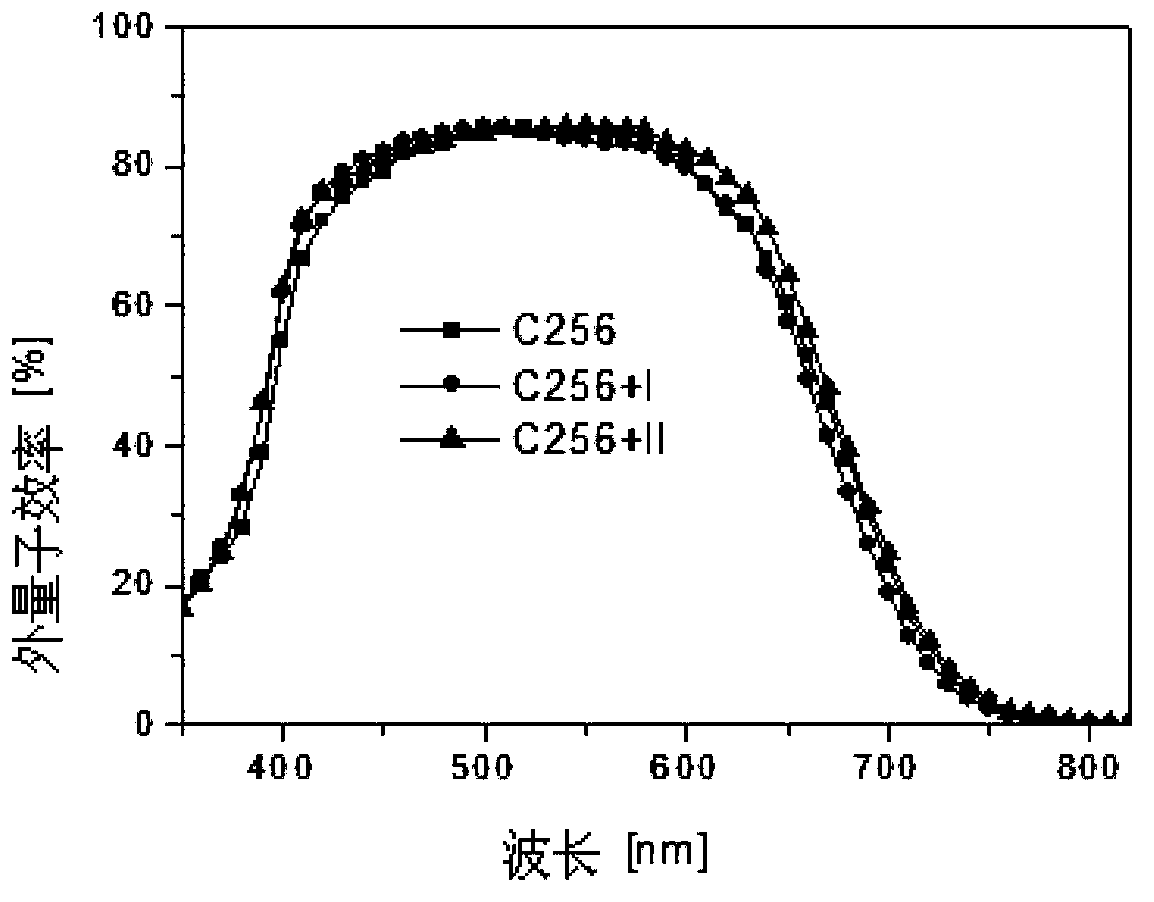

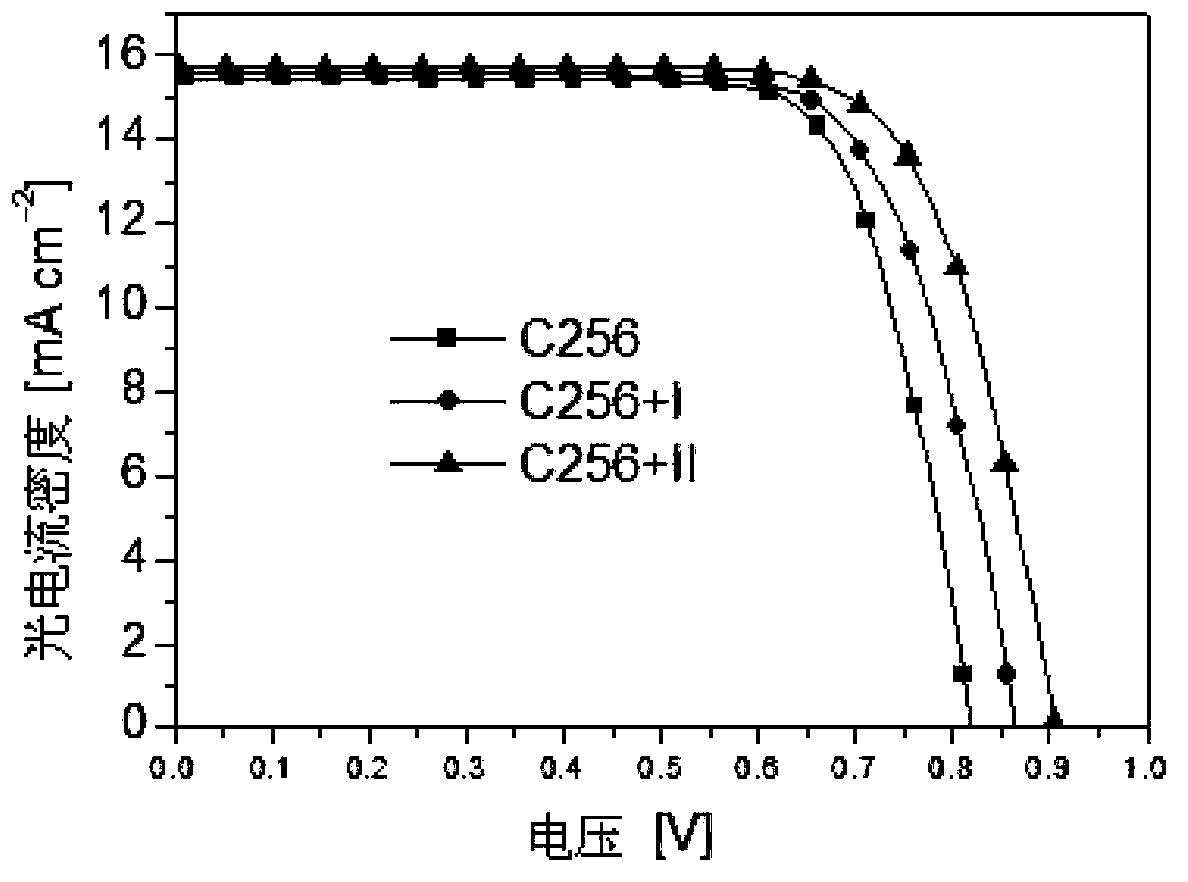

[0065] Soak the nanostructured titanium dioxide film electrode in the chlorobenzene solution containing 100 micromoles per liter of C256 dye for 12 hours for dyeing, then rinse with acetonitrile, and put the electrode into the solution containing 1 millimoles per liter of filler I or II was immersed in the acetonitrile solution for 5 minutes to fill the defects in the dye molecular layer.

[0066] The semiconductor electrode grafted with C256 dye and filler (I or II) was connected to the counter electrode covered with nano-platinum by using a 35-micron-thick thermal melting ring by means of heating and melting. The electrolyte is injected into the cavity between the two electrodes through the small hole on the counter electrode, and finally the small hole is heat-sealed with a hot-melt circular film and a cover glass to complete the preparation of the dye-sensitized solar cell. The electrolyte components are as follows: 0.25 moles per liter of tris(1,10-phenanthroline)cobalt(I...

Embodiment 2

[0069] Soak the nanostructured titanium dioxide film electrode in the chlorobenzene solution containing 100 micromoles per liter of C219 dye for 12 hours for dyeing, then rinse with acetonitrile, and put the electrode into the solution containing 1 millimoles per liter of filler I or II was immersed in the acetonitrile solution for 5 minutes to fill the defects in the dye molecular layer.

[0070] The semiconductor electrode grafted with C219 dye and filler (I or II) was connected to the counter electrode covered with nano-platinum by using a 35-micron thick thermal fusion ring by means of heating and melting. The electrolyte is injected into the cavity between the two electrodes through the small hole on the counter electrode, and finally the small hole is heat-sealed with a hot-melt circular film and a cover glass to complete the preparation of the dye-sensitized solar cell. The electrolyte components are as follows: 0.25 moles per liter of tris(1,10-phenanthroline)cobalt(II...

Embodiment 3

[0073] Soak the nanostructured titanium dioxide thin film electrode in the chlorobenzene solution containing 100 micromole per liter of C249 dye for 12 hours for dyeing, then rinse with acetonitrile, and put the electrode into the solution containing 1 millimole per liter of filler I or II was immersed in the acetonitrile solution for 5 minutes to fill the defects in the dye molecular layer.

[0074] The semiconductor electrode grafted with C249 dye and filler (I or II) was connected to the counter electrode covered with nano-platinum by using a 35-micron-thick thermal melting ring by means of heating and melting. The electrolyte is injected into the cavity between the two electrodes through the small hole on the counter electrode, and finally the small hole is heat-sealed with a hot-melt circular film and a cover glass to complete the preparation of the dye-sensitized solar cell. The electrolyte components are as follows: 0.25 moles per liter of tris(1,10-phenanthroline)cobal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com