Culture medium and preparation method of culture medium

A technology for cultivation substrate and papermaking industry, applied in the field of preparation of the cultivation substrate, can solve problems such as rising price and small quantity, and achieve the effects of small engineering quantity, low price and good social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

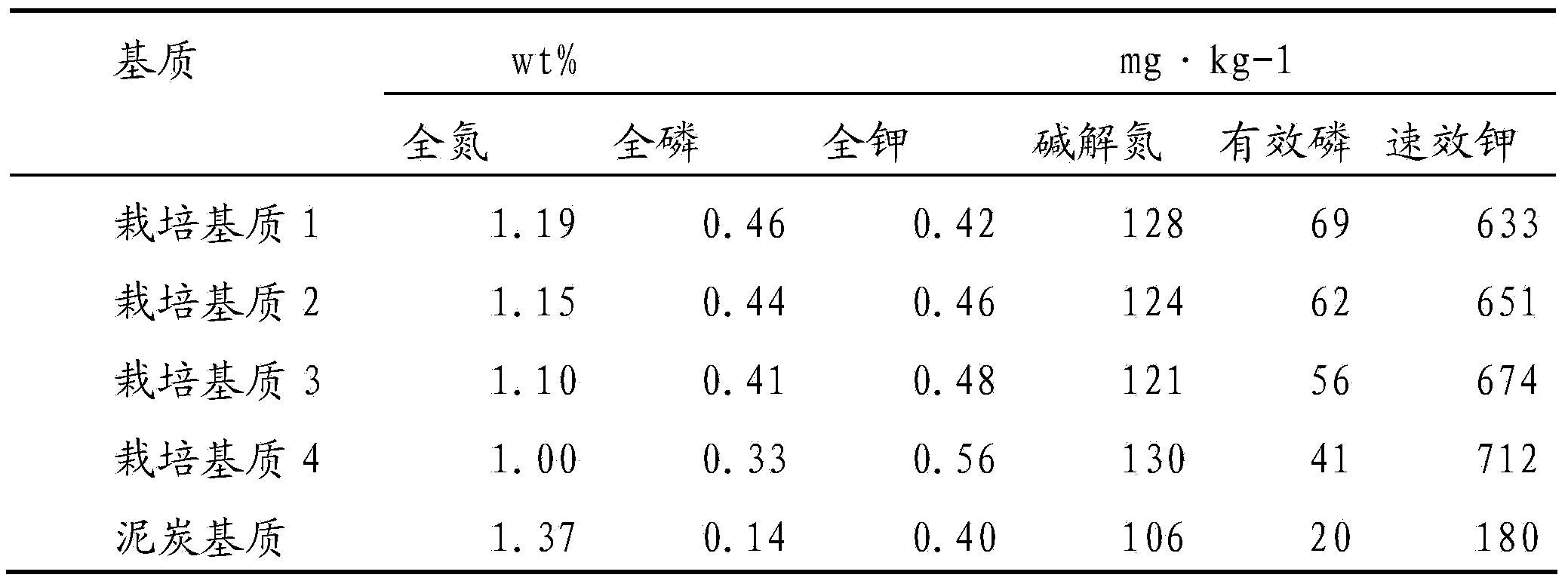

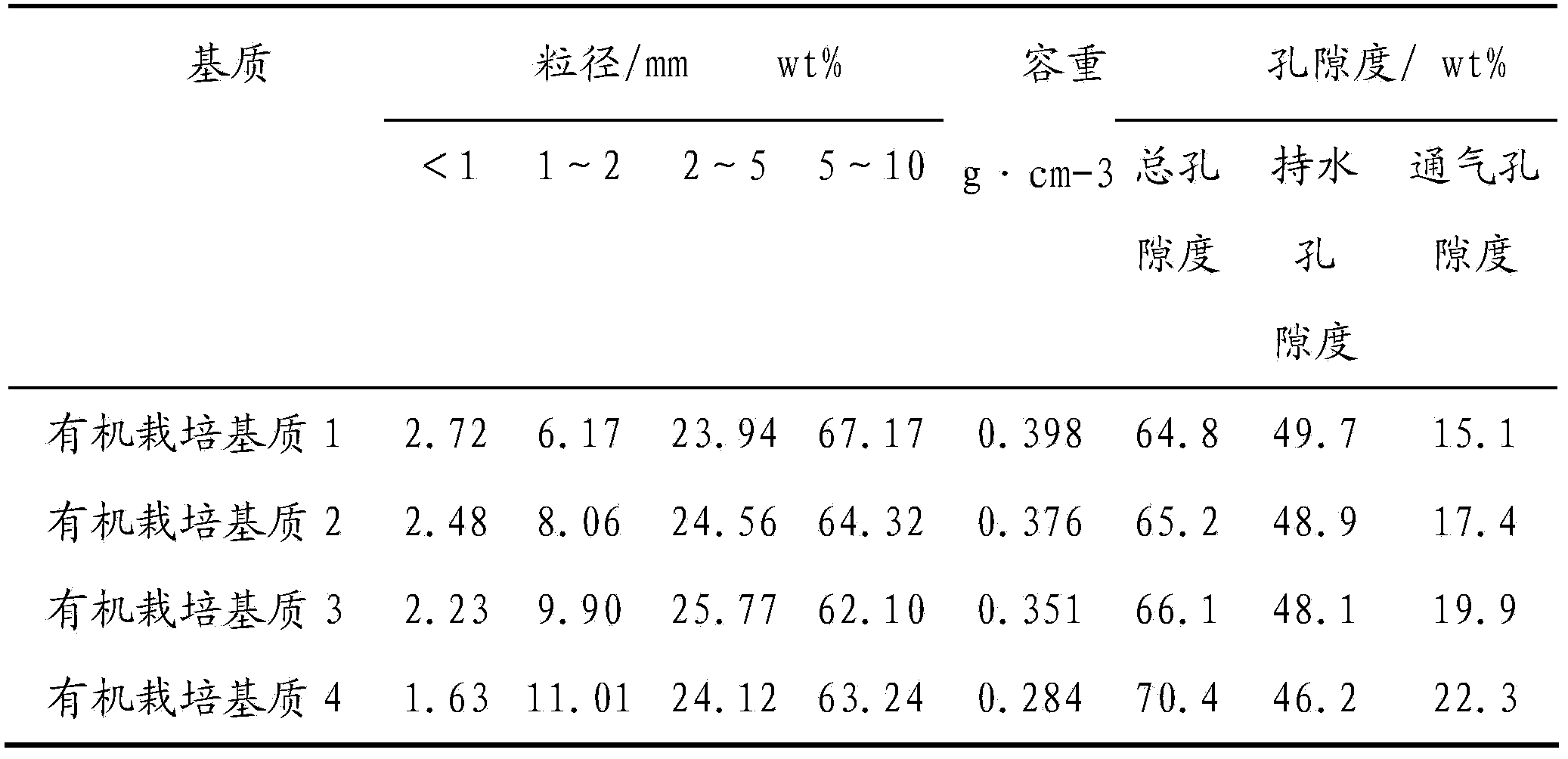

Examples

Embodiment 1

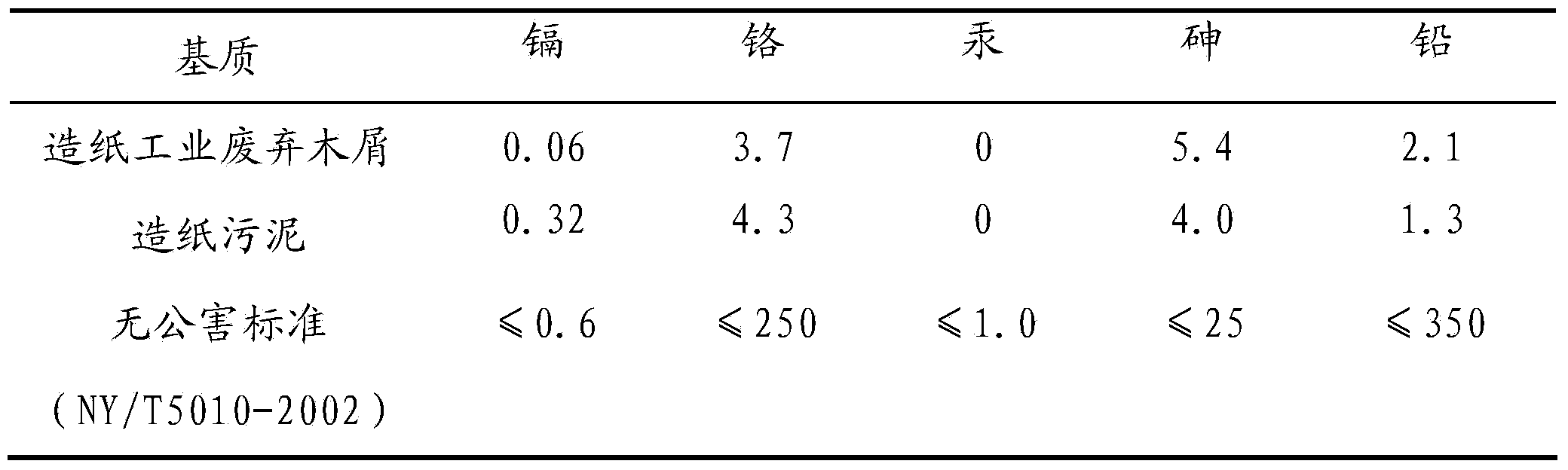

[0016] (1) Fermentation treatment steps of paper industry waste sawdust: Add 2kg of urea to each cubic meter of paper industry waste sawdust after sieving, add superphosphate to adjust pH to 8, add 0.25wt% of Bacillus subtilis , and adjust the moisture to a moisture content of 70wt%. After mixing evenly, turn over and ferment regularly. After the temperature rises to 60°C, keep it for 7 days, and cool it down in the air for later use.

[0017] (2) The composting treatment of papermaking sludge includes the following steps: firstly treat the papermaking sludge to a moisture content of 55wt%, and then undergo a static pile-type aerobic composting treatment under ventilated conditions, dry it in the air, and crush it for later use.

[0018] (3) Mix the waste sawdust, perlite, and sand from the papermaking industry after fermentation treatment obtained in step (1) and the composted papermaking sludge obtained in step (2) at a ratio of 2:2:1:5 to obtain a cultivation substrate 1. ...

Embodiment 2

[0020] (1) Fermentation treatment steps of paper industry waste sawdust: Add 1.5kg of urea to each cubic meter of paper industry waste sawdust after sieving, add superphosphate to adjust pH to 7, add 0.2wt% subtilis spores Bacillus, and adjust the moisture to a moisture content of 60wt%. After mixing evenly, turn over and ferment regularly. After the temperature rises to 60°C, keep it for 7 days, and then cool it down in the sun for later use.

[0021] (2) The composting treatment of papermaking sludge includes the following steps: firstly treat the papermaking sludge to a moisture content of 50wt%, and then undergo a static pile-type aerobic composting treatment under ventilated conditions, dry it in the air, and crush it for later use.

[0022] (3) Mix the waste sawdust, perlite, and sand from the papermaking industry after fermentation treatment obtained in step (1) and the composted papermaking sludge obtained in step (2) at a ratio of 3:3:2:6 to obtain a cultivation substr...

Embodiment 3

[0024] (1) Fermentation treatment steps of paper industry waste sawdust: Add 1.5kg of urea to each cubic meter of paper industry waste sawdust after sieving, add superphosphate to adjust pH to 7, add 0.15wt% subtilis spores Bacillus, and adjust the moisture to a moisture content of 55wt%. After mixing evenly, turn over and ferment regularly. After the temperature rises to 60°C, keep it for 6 days, and cool it down in the sun for later use.

[0025] (2) The composting treatment of papermaking sludge includes the following steps: first, the papermaking sludge is treated to a moisture content of 45wt%, and then it is subjected to static pile-type aerobic composting under ventilated conditions, air-dried, crushed and then used for later use.

[0026] (3) Mix the fermented waste sawdust, perlite, and sand from the papermaking industry obtained in step (1) and the composted papermaking sludge obtained in step (2) at a ratio of 2.5:2.5:1:5.5 to obtain a cultivation substrate 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com