Load-type dearsenic agent and preparation method

A load-type, arsenic-removing technology, which is applied in chemical instruments and methods, and other chemical processes, can solve the problems that it is difficult to further improve the adsorption capacity and arsenic removal rate of the arsenic-removing agent, uneven distribution of pores and pore sizes, and small specific surface area. , to achieve enhanced adsorption, uniform dispersion of pores and pore sizes, and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

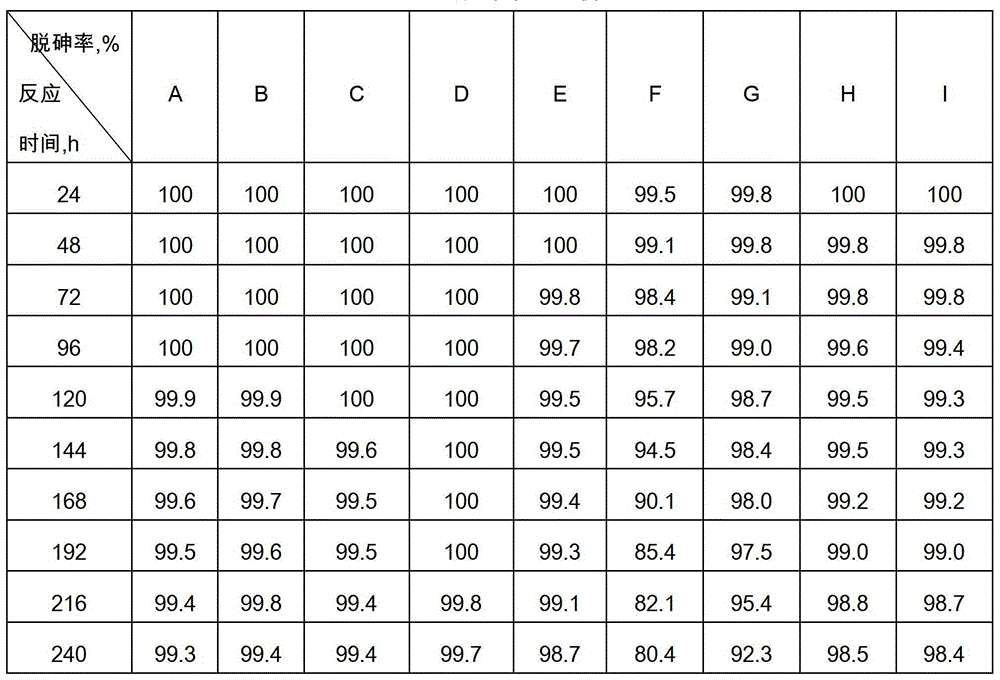

Embodiment 1

[0030] The load-type arsenic removal agent described in this example is composed of a carrier and an active component, the carrier is a wood activated carbon carrier, the active component is copper oxide, and the copper oxide is in the total weight of the load-type arsenic removal agent The mass fraction is 10wt%.

[0031] The preparation method of the loaded arsenic removal agent described in this embodiment comprises the following steps:

[0032](1) Pretreatment of the activated carbon carrier: at 50°C, impregnate the activated carbon carrier with a nitric acid solution with a mass concentration of 5% for 2 hours, and control the mass ratio of the nitric acid solution to the activated carbon carrier to be 3:1, and then Drying at 120°C for 8 hours, and roasting at 300°C for 2 hours under the protection of nitrogen to obtain the pretreated activated carbon carrier;

[0033] (2) Preparation of loaded arsenic removal agent:

[0034] a. Weigh 39.5g of basic copper carbonate, 37...

Embodiment 2

[0037] The load-type arsenic removal agent described in this embodiment is composed of a carrier and an active component, the carrier is coal-based activated carbon carrier, the active component is copper oxide, and the total weight of the copper oxide in the load-type arsenic removal agent The mass fraction in is 11wt%.

[0038] The preparation method of the loaded arsenic removal agent described in this embodiment comprises the following steps:

[0039] (1) Pretreatment of the activated carbon carrier: at 25°C, the activated carbon carrier was impregnated with a nitric acid solution with a mass concentration of 5% for 3 hours, and the mass ratio of the nitric acid solution to the activated carbon carrier was controlled to be 3:1, and then Drying at 110°C for 9 hours, and roasting at 200°C for 3 hours under the protection of nitrogen to obtain the pretreated activated carbon carrier;

[0040] (2) Preparation of loaded arsenic removal agent:

[0041] a. Weigh 40g of copper s...

Embodiment 3

[0044] The load-type arsenic removal agent described in this embodiment is composed of a carrier and an active component, the carrier is coal-based activated carbon carrier, the active component is copper oxide, and the total weight of the copper oxide in the load-type arsenic removal agent The mass fraction in is 12wt%.

[0045] The preparation method of the loaded arsenic removal agent described in this embodiment comprises the following steps:

[0046] (1) Pretreatment of the activated carbon carrier: at 20°C, the activated carbon carrier was impregnated with a nitric acid solution with a mass concentration of 5% for 5 hours, and the mass ratio of the acid solution to the activated carbon carrier was controlled to be 3:1, and then Dry at 120°C for 8 hours, and roast at 500°C for 1 hour under the protection of nitrogen to obtain the pretreated activated carbon carrier;

[0047] (2) Preparation of loaded arsenic removal agent:

[0048] a. Weigh 104g of copper nitrate and ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com