A kind of transparent composite plate and preparation method thereof

A composite sheet and transparent technology, applied in the field of materials, can solve the problems of high production cost, poor energy saving effect, laminated glass bubbles, etc., and achieve high production efficiency, good sound insulation performance, and good heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 Transparent composite sheet and its preparation method (1)

[0029] The glass in this embodiment is float glass with a thickness of 4 mm; the thermoplastic resin plate is polystyrene (PS) with a thickness of 3 mm; the film is EVA with a thickness of 0.76 mm.

[0030] (1) Pretreatment: Dry the PS board in an oven at 50°C for 100 minutes, then cool it down to room temperature naturally in the oven;

[0031] (2) Clean the ordinary glass, air dry it, and wipe it with a dust-free cloth;

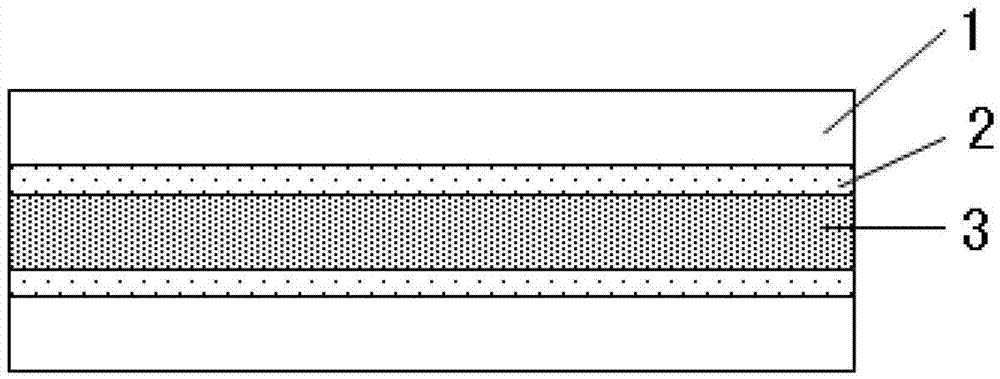

[0032] (3) Combine common glass, EVA film and PS board in a clean room, see figure 1 . Lamination conditions are: temperature 25°C, humidity <30%;

[0033] (4) After assembling, put the sample in a vacuum bag, and carry out composite molding in a glass vacuum heat-sealing folder. Process parameters: preheat at a low temperature of 50°C for 40 minutes, then heat at a high temperature of 75°C for 110 minutes, and a pressure of 0.092MPa;

[0034] (5) After composite molding, i...

Embodiment 2

[0036] Embodiment 2 transparent composite sheet and its preparation method (2)

[0037] The glass in this embodiment is ordinary float glass with a thickness of 3 mm, the thermoplastic resin plate is polycarbonate (PC), 2 mm; the film is EVA, 1.52 mm.

[0038] (1) Pretreatment: Dry the PC board in an oven at 70°C for 90 minutes, and naturally cool it to room temperature in the oven;

[0039] (2) Clean the ordinary glass, air dry it, and wipe it with a dust-free cloth;

[0040] (3) Combine ordinary glass, EVA film and PC board in a clean room. First place the glass flat, lay the film on the upper layer, place the thermoplastic resin plate on the film, and then lay the film on the upper layer of the thermoplastic resin plate. Finally, place the glass; the three-layer board needs to be laid flat, and the film needs to be laid flat. Lamination conditions are temperature 25°C, humidity <30%;

[0041] (4) After assembling, put the sample in a vacuum bag, and carry out composite m...

Embodiment 3

[0045] The glass in this embodiment is ordinary glass, 5 mm, the thermoplastic resin plate is organic glass (PMMA), 1.5 mm; the film is PU, 0.38 mm.

[0046] (1) Pretreatment: Dry the PMMA plate in an oven at 60°C for 100 minutes, and naturally cool it to room temperature in the oven;

[0047] (2) Clean the ordinary glass, air dry it, and wipe it with a dust-free cloth;

[0048](3) Combining ordinary glass, PU film and PMMA board in a clean room, the combination sequence is the same as in Example 2, and the combination conditions are temperature 25°C and humidity <30%;

[0049] (4) After assembling, put the sample in a vacuum bag, and carry out composite molding in a vacuum heat-sealing folder. Process parameters: preheat at a low temperature of 40°C for 30 minutes, then heat at a high temperature of 80°C for 80 minutes, and a pressure of 0.095MPa;

[0050] (5) After composite molding, cool to 60°C in the laminating machine and take it out.

[0051] The light transmittance o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com