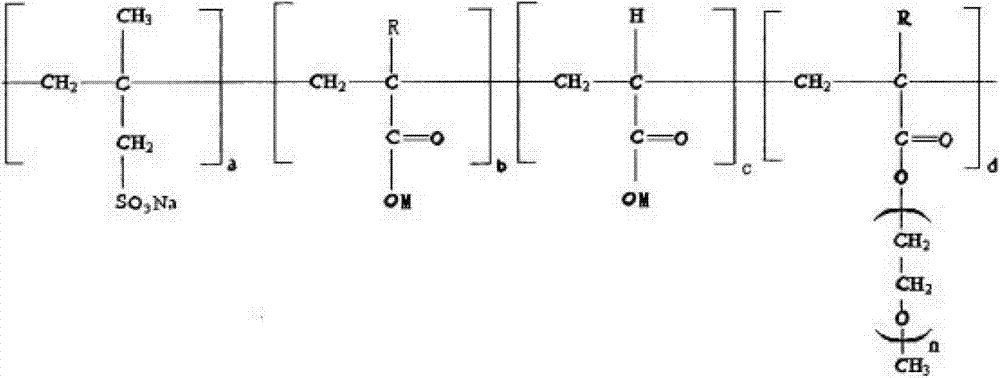

Carboxylate water reducing agent and preparation method thereof

A technology of water reducer and polycarboxylate, applied in the field of high performance polycarboxylate water reducer, can solve the problems of poor slump retention, low water reduction rate of products, complex production process of water reducer, etc., and achieve stable product performance , product adaptability, excellent performance and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

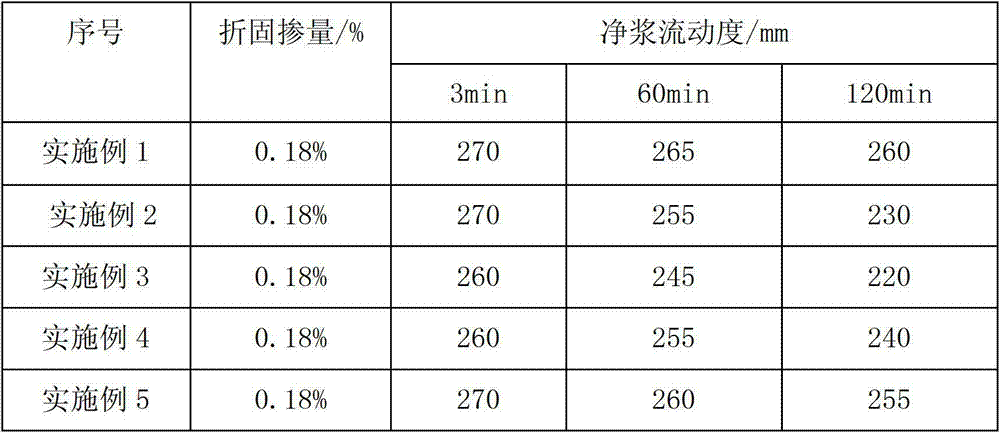

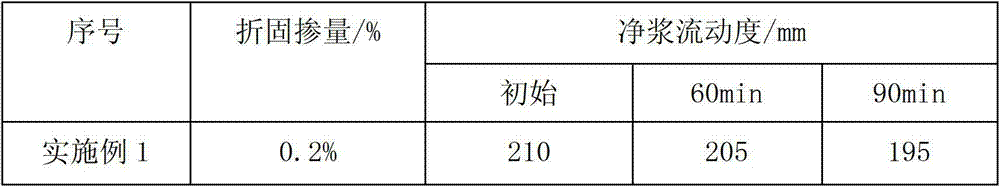

Embodiment 1

[0028] Put 150.00 parts of HPEG with a molecular weight of 2400 and 100 parts of water into a reaction container, raise the temperature, and stir at a temperature of 35±5°C to completely dissolve the reactants, add 1.5 parts of 30% hydrogen peroxide solution, and then drop into the container Solubilize the aqueous solution of 18.00 parts of acrylic acid + 4.94 parts of sodium methacrylate + 40 parts of water and the aqueous solution of 0.45 parts of Vc + 0.45 parts of mercaptopropionic acid + 60 parts of water. After completion, keep the temperature at 35±5°C and continue the reaction for 1 hour. After cooling, about 30% sodium hydroxide solution is added to adjust the pH to 6±1 to obtain the 45% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 2

[0030] Put 150.00 parts of TPEG with a molecular weight of 2400 and 100 parts of water into a reaction container, raise the temperature, and stir at a temperature of 35±5°C to completely dissolve the reactants, add 1.5 parts of 30% hydrogen peroxide solution, and then drop into the container Solubilize the aqueous solution of 13.50 parts of acrylic acid + 5.375 parts of methacrylic acid + 4.94 parts of sodium methacryl sulfonate + 40 parts of water and the aqueous solution of 0.45 parts of Vc + 0.45 parts of mercaptopropionic acid + 60 parts of water, control the dropping speed, respectively Dropping is completed at 3h and 3.5h, keep the temperature at 35±5°C, and continue the reaction for 1 hour. After cooling, about 30% sodium hydroxide solution is added to adjust the pH to 6±1 to obtain the 45% polycarboxylate high-performance concrete water reducer of the present invention.

Embodiment 3

[0032] Put 150.00 parts of TPEG with a molecular weight of 2400 and 100 parts of water into a reaction container, raise the temperature, and stir at a temperature of 35±5°C to completely dissolve the reactants, add 1.5 parts of 30% hydrogen peroxide solution, and then drop into the container Solubilize the aqueous solution of 13.50 parts of acrylic acid + 4.94 parts of sodium methacryl sulfonate + 40 parts of water and the aqueous solution of 0.45 parts of Vc + 0.45 parts of thioglycolic acid + 60 parts of water, control the dropping speed, and finish dropping in 3 hours and 3.5 hours respectively , keep the temperature at 35±5°C, and continue the reaction for 1 hour. After cooling, about 40% sodium hydroxide solution is added to adjust the pH to 6±1 to obtain the 45% polycarboxylate high-performance concrete water reducer of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com