High temperature resistant toughening retarder

A technology of high temperature resistance and retarder, used in drilling compositions, chemical instruments and methods, etc., can solve the problems of lack of toughening effect, high dosage sensitivity, loss of retardation effect, etc., and achieve thickening time Adjustable, good settlement stability, good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The relevant parameters in the preparation process of high temperature resistant toughening retarder are as follows:

[0024] Sepiolite mesh number (mesh): 300

[0025] Nitric acid concentration (mol / L): 0.4

[0026] Sepiolite acid activation stirring speed (r / min): 120

[0027] Sepiolite acid activation time (h): 3

[0028] Sepiolite roasting temperature (°C): 110

[0029] Seafoolite roasting time (h): 2

[0031] Mass of boric acid (g): 88

[0032] Mass of sepiolite for adsorption (g): 25

[0033] Volume of boric acid-borax solution for adsorption (mL): 450

[0034] Adsorption time (h): 2

[0035] Spray drying temperature (°C): 150

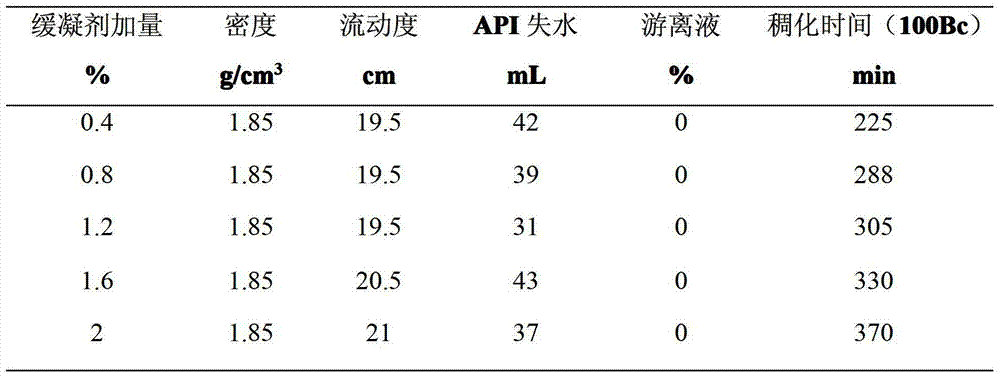

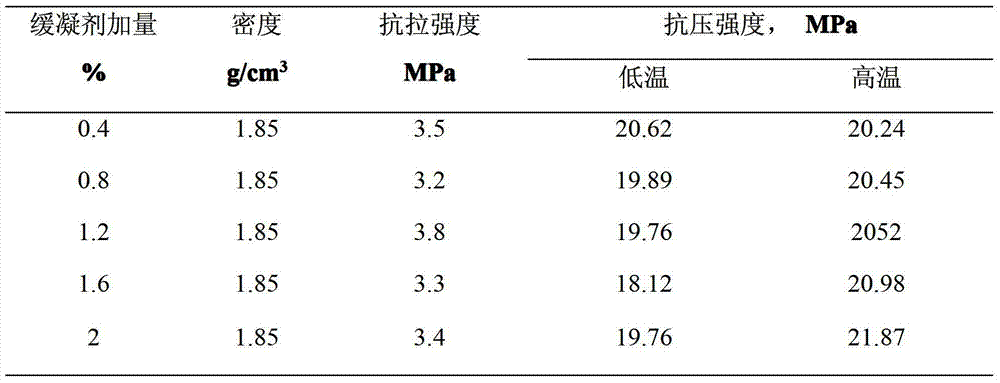

[0036] Preparation of cement slurry for well cementing: Weigh 100 parts by weight of oil well cement, 40 parts by weight of quartz sand, 3 parts by weight of hydroxyethyl cellulose dry mix into dry powder, measure 61 parts of water, 0.4 to 2 parts by weight of high temperature resistant toughening retar...

Embodiment 2

[0040] The relevant parameters in the preparation process of high temperature resistant toughening retarder are as follows:

[0041] Sepiolite mesh number (mesh): 500

[0042] Nitric acid concentration (mol / L): 1.5

[0043] Sepiolite acid activation stirring speed (r / min): 120

[0044] Sepiolite acid activation time (h): 3.5

[0045] Sepiolite roasting temperature (°C): 115

[0046] Seafoolite roasting time (h): 2

[0048] Mass of boric acid (g): 70

[0049] Mass of sepiolite for adsorption (g): 26

[0050] Volume of boric acid-borax solution for adsorption (mL): 500

[0051] Adsorption time (h): 2

[0052] Spray drying temperature (°C): 180

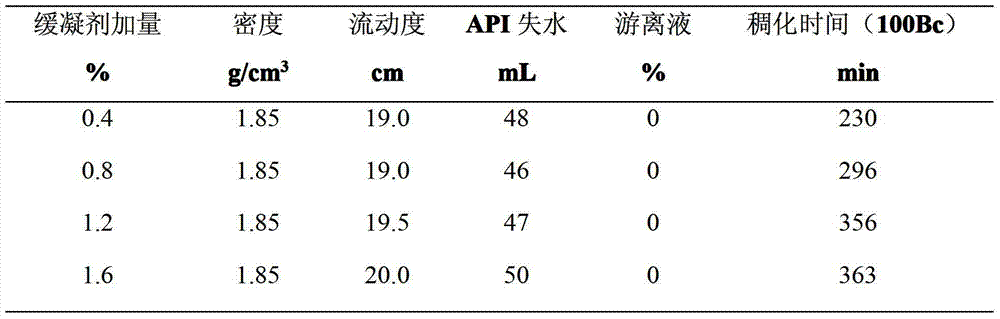

[0053] Preparation of cement slurry for well cementing: Weigh 100 parts by weight of oil well cement, 40 parts by weight of slag, 2.5 parts by weight of hydroxyethyl cellulose and dry mix it into a dry powder, measure 60 parts of water, and 0.4 to 2.5 parts by weight of high temperature resistant toug...

Embodiment 3

[0057] The relevant parameters in the preparation process of high temperature resistant toughening retarder are as follows:

[0058] Sepiolite mesh number (mesh): 800

[0059] Nitric acid concentration (mol / L): 0.6

[0060] Sepiolite acid activation stirring speed (r / min): 130

[0061] Sepiolite acid activation time (h): 5

[0062] Sepiolite roasting temperature (°C): 140

[0063]Seafoolite roasting time (h): 2.5

[0064] Borax mass (g): 36

[0065] Mass of boric acid (g): 64

[0066] Mass of sepiolite for adsorption (g): 28

[0067] Volume of boric acid-borax solution for adsorption (mL): 550

[0068] Adsorption time (h): 2.5

[0069] Spray drying temperature (°C): 200

[0070] Preparation of cement slurry for well cementing: Weigh 100 parts by weight of oil well cement, 30 parts by weight of fly ash, 1.5 parts by weight of hydroxyethyl cellulose dry mix into dry powder, measure 60 parts of water, 0.4 to 2.5 parts by weight of high temperature resistant toughening sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com