Pistons with clearance paired energy-saving and environment-friendly piston rings

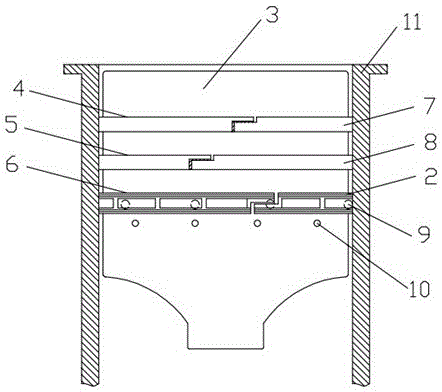

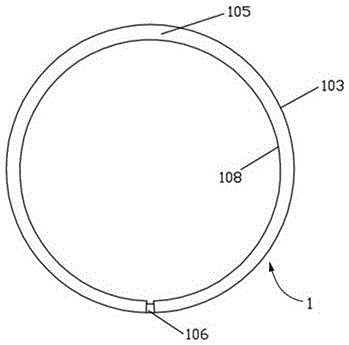

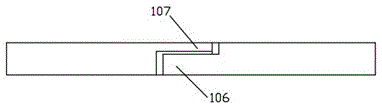

An energy-saving, environment-friendly, and installation-clearance technology, applied in pistons, engine components, machines/engines, etc., can solve the problems of inability to achieve sealing effect, decrease in internal combustion engine power performance, and decrease in cylinder compression pressure, avoiding pumping effects and reducing direct pressure. impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: The piston of the present invention is installed in the NQ160 engine of the No. 248 car fleet of No. 2 Bus Company of Chongqing Public Transport Group. Cylinder inner diameter 105+ , The outer diameter of the piston is 104.82 mm. Before installation, the car has been in a state of fuel consumption loss. The oil consumption is 0.7 liters of oil every 3-5 days. After installation, the oil consumption is 0.7 liters of oil every 20-23 days. The average fuel saving (compared with another new original engine replaced at the same time) is 12.47%, which greatly saves fuel and oil.

Embodiment 2

[0031] Example 2: The piston of the present invention was installed on the "X6130Z7" (excavator) produced by China National Heavy Duty Truck Hangzhou Diesel Engine Factory. The fuel consumption per hour before installation was 42.3 liters, and the fuel consumption per hour after installation was reduced to 30.46 liters, a drop of up to 28%, the engine power increased by 11.27%.

Embodiment 3

[0032] Example 3: The piston of the present invention was installed on 30 "Hengtong Front Newman" engines of the Second Bus Company of Chongqing Public Transport Group for trial use. The gas consumption was 47.3m per 100 kilometers before installation. 3 / Car, 41.7m per 100 kilometers after installation 3 / Car, the air-saving rate reaches 11.27%, the maximum air-saving rate is 14.28%, the power is increased by about half a gear, and the torque is increased by about one gear.

[0033] It can be seen that the piston of the present invention enables the fuel to be fully combusted at all times, greatly reduces fuel consumption and engine oil consumption, reduces emissions of harmful substances, greatly improves various mechanical performance indicators and economic indicators of internal combustion engines, and truly solves the problem of high power in the industry. The historical problems of diesel engines with high fuel consumption and high emissions have good promotion value and app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com