Motor reversing driving reciprocating pump

A technology of reciprocating pumps and reversing belts, which is applied in the direction of machines/engines, pumps, piston pumps, etc., and can solve the problems of high stroke times, displacement, large discharge pressure fluctuations, and short service life of wearing parts in reciprocating pumps and reciprocating compressors. problem, to achieve the effect of improving work efficiency, stable transmission and large bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

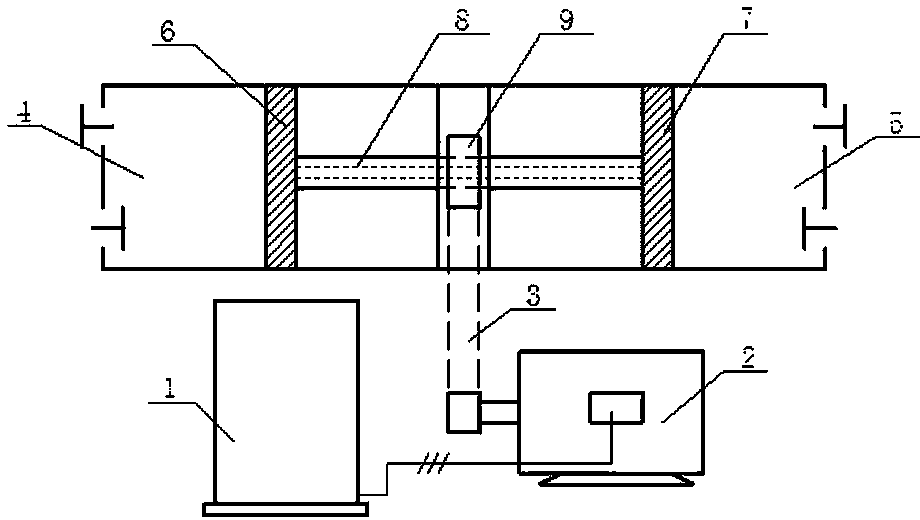

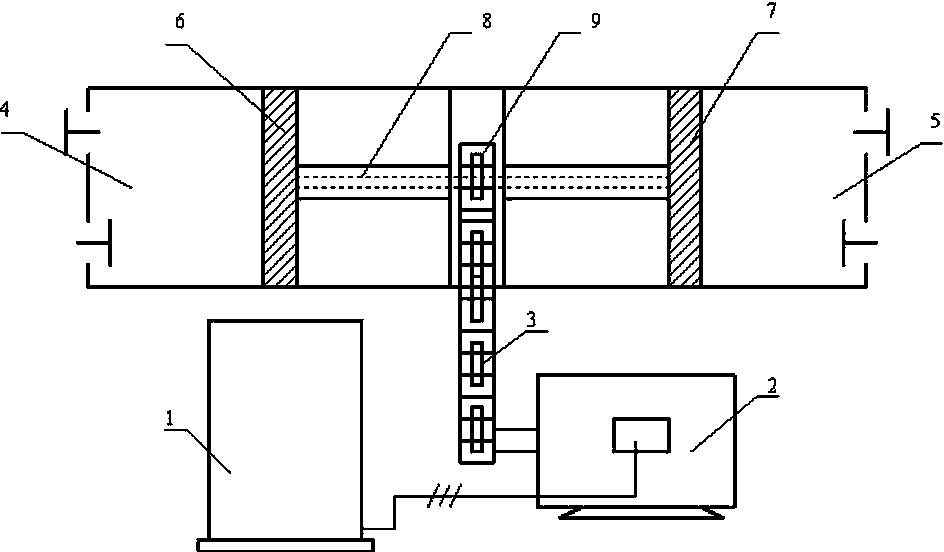

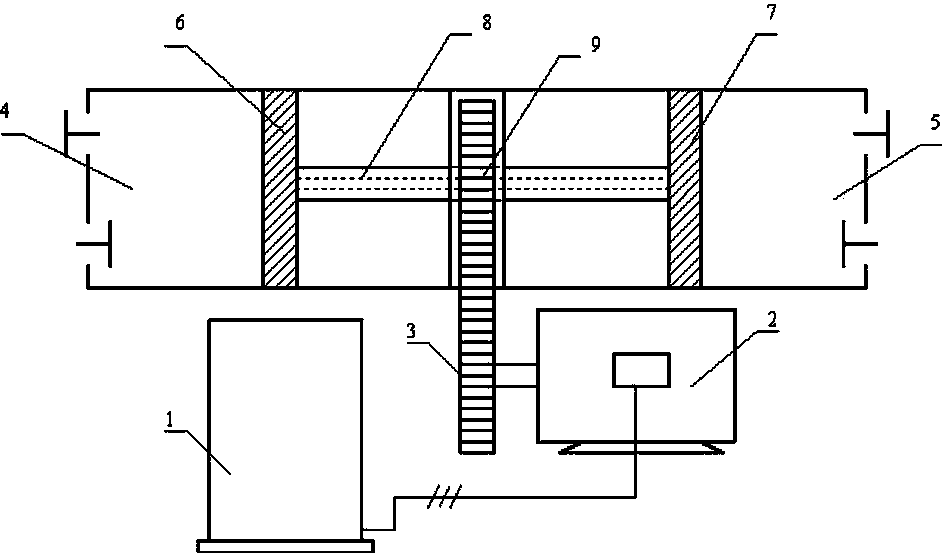

[0030] In order to further disclose the technical solutions of the present invention, the following will be described in detail through examples in conjunction with the accompanying drawings:

[0031] a. Motor reversing belt drive reciprocating pump,

[0032] like figure 1 , the control system of the motor control cabinet 1 makes the motor 2 rotate forward, drives the nut type pulley 9 to rotate through the belt 3, and the nut type pulley 9 rotates to push the screw type piston rod 8 to run from left to right, and the right end of the screw type piston rod 8 The right piston 7 compresses and discharges the fluid in the right piston cylinder 5, while the left piston 6 on the left side of the screw type piston rod 8 sucks the fluid into the left piston cylinder 4: when the right piston 7 reaches the rightmost side of the right piston cylinder 5, the piston The position sensor sends a signal to the motor control cabinet 1, and the motor control system reverses the motor 2, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com