Method for treating high-salt organic wastewater by activating peroxymonosulfate with magnetic copper oxide

A technology of organic waste water and monosulfate, which is used in oxidation water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., to achieve the effect of simple synthesis route, good reusability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

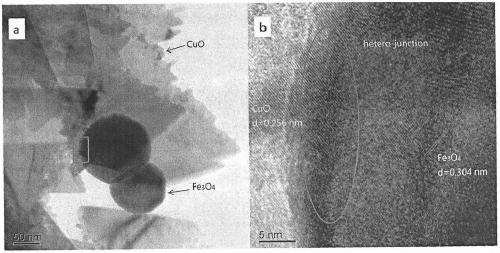

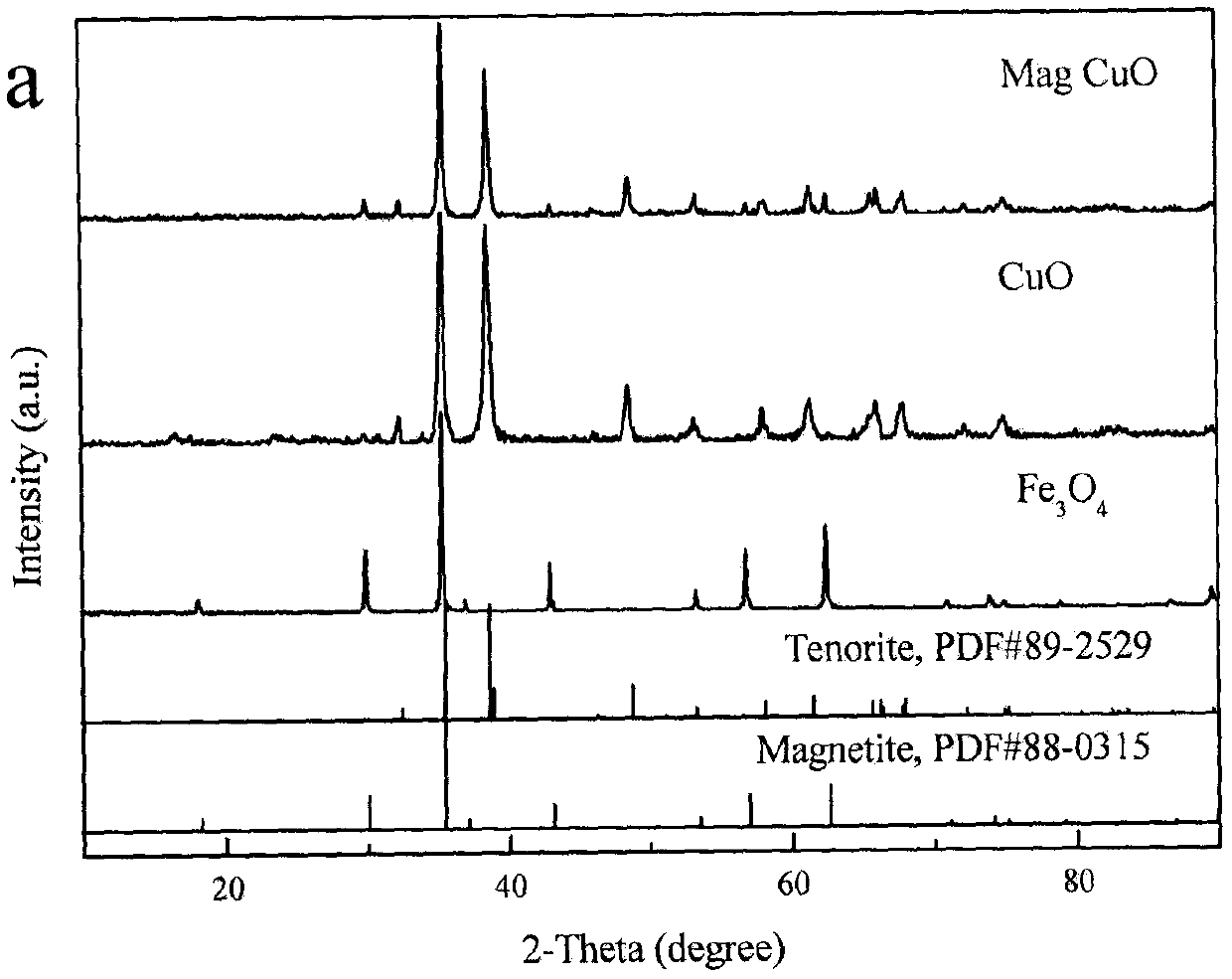

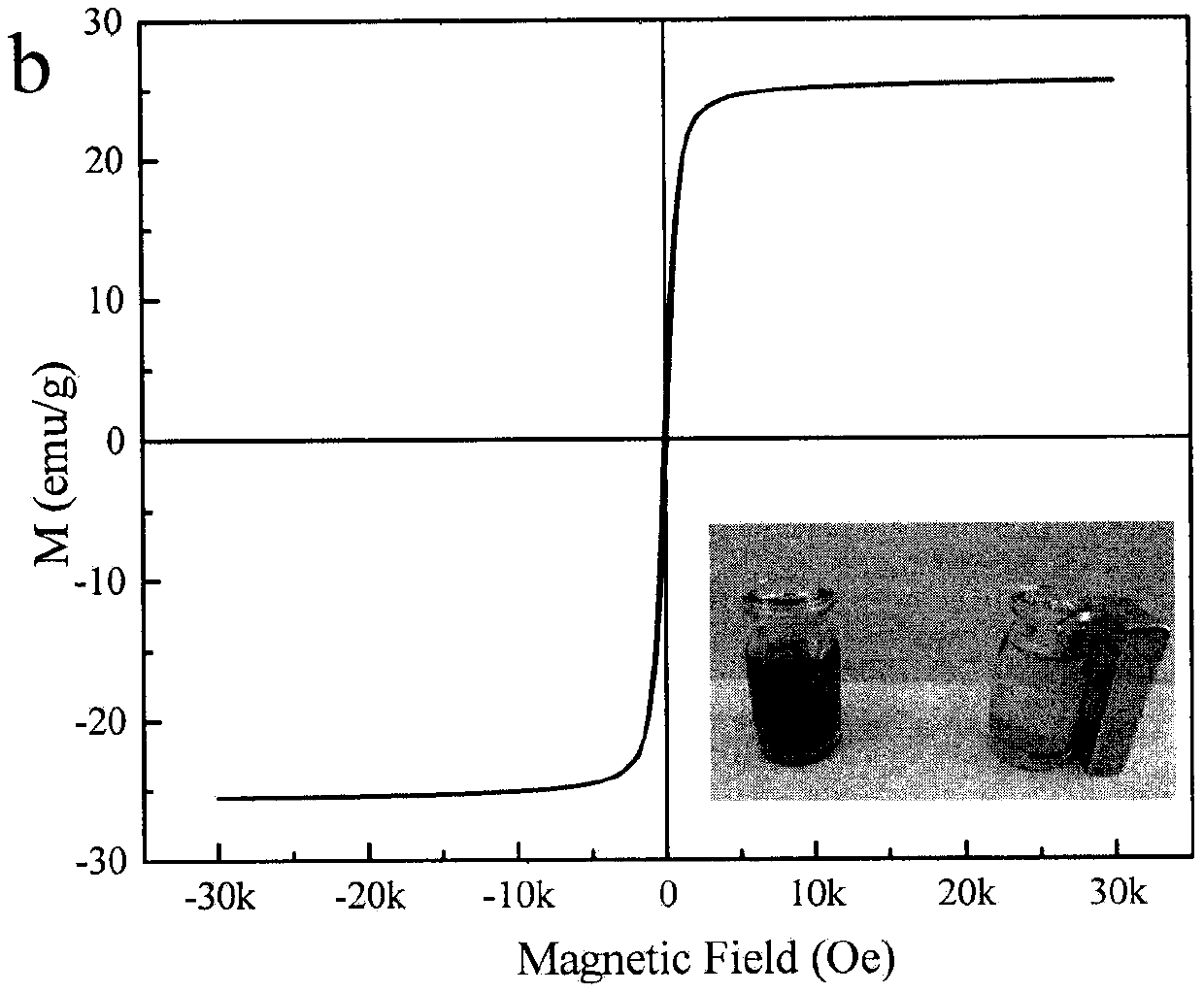

Embodiment 1

[0034] Weigh 9.0815g of copper acetate and 1.1577g of nanometer iron ferric oxide and dissolve them in 200mL of deionized water, stir continuously, add 0.1mL of 1-mercaptoglycerol as a dispersant, and ultrasonically 30min to form a uniformly dispersed solution; keep stirring Add 50mL of sodium hydroxide solution (4mol / L) dropwise to the above solution to form a brown suspension, and keep stirring for 1 hour, then leave it to stand for 2 hours to age to form a black solid precipitate; then separate with a permanent magnet, and use After repeated washing with water, ethanol and distilled water, the magnetic copper oxide nanosheets are obtained by drying in an oven not higher than 80°C. For use, add 2 mM peroxymonosulfate to a solution containing 0.1 mM Acid Orange 7 and 0.2 M Na 2 SO 4 In the high-salt dye wastewater, adjust the pH to neutral, then add 0.1g / L magnetic copper oxide material, keep stirring, the degradation rate of Acid Orange 7 reaches 95.81% within 30min, as F...

Embodiment 2

[0036] 2mM persulfate was added to 0.1mM methylene blue, 0.1mM rhodamine B and 0.09mM atrazine high salt (0.2M Na 2 SO 4 ) in organic wastewater, adjust the pH to neutral, then add 0.1g / L magnetic copper oxide material, keep stirring constantly, the degradation rates of methylene blue, rhodamine B and atrazine after 30min are 74.57%, 100% respectively and 100%, such as Figure 5 As shown, the method in the present invention exhibits high efficiency removal ability for various organic pollutants.

Embodiment 3

[0038] Add 2mM persulfate to the high-salt dye wastewater containing 0.1mM Acid Orange 7 and different concentrations of inorganic salts, then add 0.1g / L magnetic copper oxide, keep stirring, Acid Orange 7 within 30min The degradation rate and degradation rate constant are as follows, no matter in single salt or multiple mixed brines, the removal rate of acid orange 7 by the method of the present invention is more than 80%, showing that the method is applicable to the removal of organic matter in various inorganic salt wastewater .

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com