Flexible packaging material with oxygen adsorption function based on natural gallic acid, preparation method for the packaging material and application of the packaging material

A gallic acid and flexible packaging technology, applied in the field of packaging materials, can solve the problems of small contact area, low oxygen absorption efficiency, accidental ingestion, etc., and achieve the effects of increasing the contact area, assisting in regulating the oxygen absorption reaction rate, and improving the oxygen absorption efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described through the following specific embodiments and application examples. The following specific descriptions are for the convenience of understanding the present invention, and are not intended to limit the protection scope of the present invention.

[0022] 1 raw material

[0023] Commodity KBOPP film; LD100AC type LDPE resin; F280 type polypropylene resin; 18-0.3 type EVA resin; EVA emulsion type BJ707, solid content 55%; polyurethane adhesive; polyacrylic acid type adhesive.

[0024] 1 Preparation of food contact layer (inner layer)

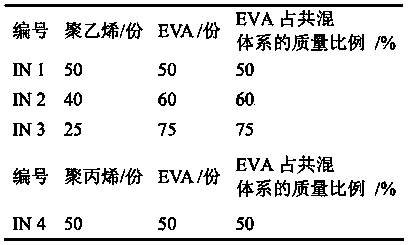

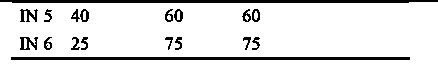

[0025] The composition of the food contact layer of the oxygen-absorbing film is shown in Table 1; EVA and polyethylene (or polypropylene) resins are mixed mechanically, and then melt-blended on a twin-screw extruder at 145-180°C (see Table 2 for polyethylene), Then it is prepared into modified polyethylene or polypropylene film. For polypropylene resin processing at 170-210°C.

[0026] Ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

| Oxygen permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com