Titanium powder coated with oxygen impurity adsorbent and preparation method of titanium powder

An adsorbent and impurity technology, which is applied in the field of titanium powder coated with oxygen impurity adsorbent and its preparation, can solve the problems of insufficient oxygen impurity adsorption capacity, low activity, uneven dispersion, etc., and achieves small size, high activity and impurities. Low content and good dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] 1. Hydrodehydrogenation Ti-6Al-4V powder is selected as the raw material, the purity is 98.5%, and the particle size is -200 mesh. Weigh the powder with a mass of 50g and pour it into a conical fluidized bed reactor. The material of the fluidized bed is high-purity quartz. The plate is a quartz sintered plate, the diameter of the cylindrical casing is 60mm, and the diameter of the air inlet and air outlet is 8mm.

[0050] 2. Connect the raw material container heating system, gas control system, fluidized bed reactor, heating system and tail gas treatment device through silicone tubes, check the air tightness, and pass high-purity argon to discharge the air in the entire system at a gas velocity of 0.5 L / min, exhaust time is 60min.

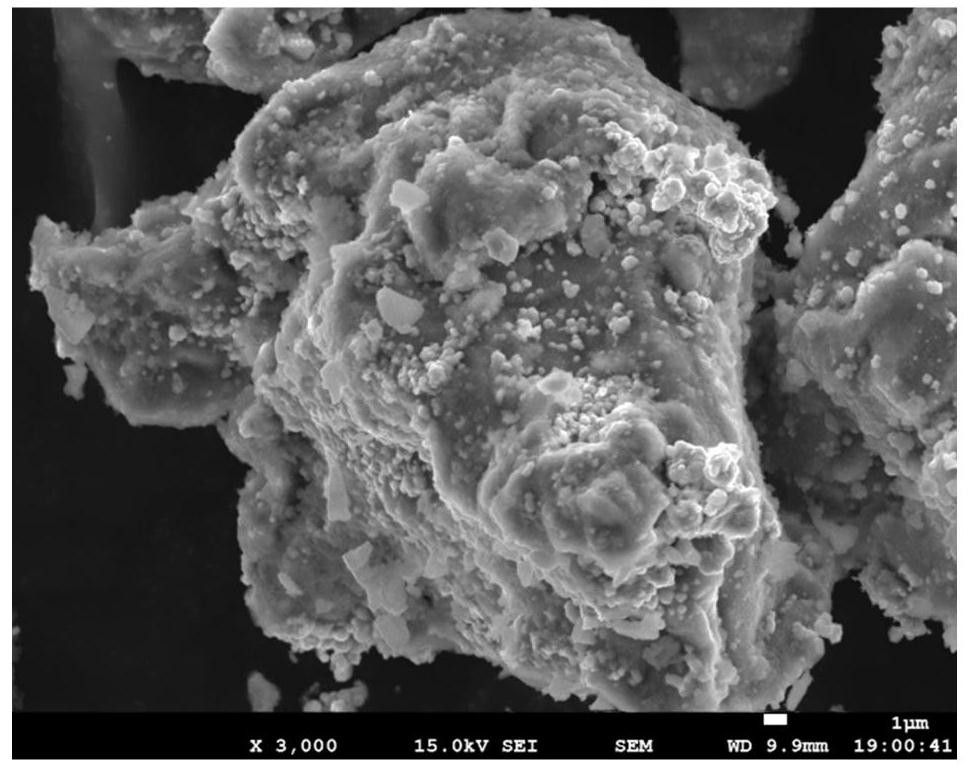

[0051] 3. Start the heating system of the fluidized bed reactor in step 1). After the temperature is raised to 900° C., the powder raw material is added to the fluidized bed reactor, and 0.3 L / min of boron trichloride gas, 0.6 L / min of hyd...

Embodiment 2

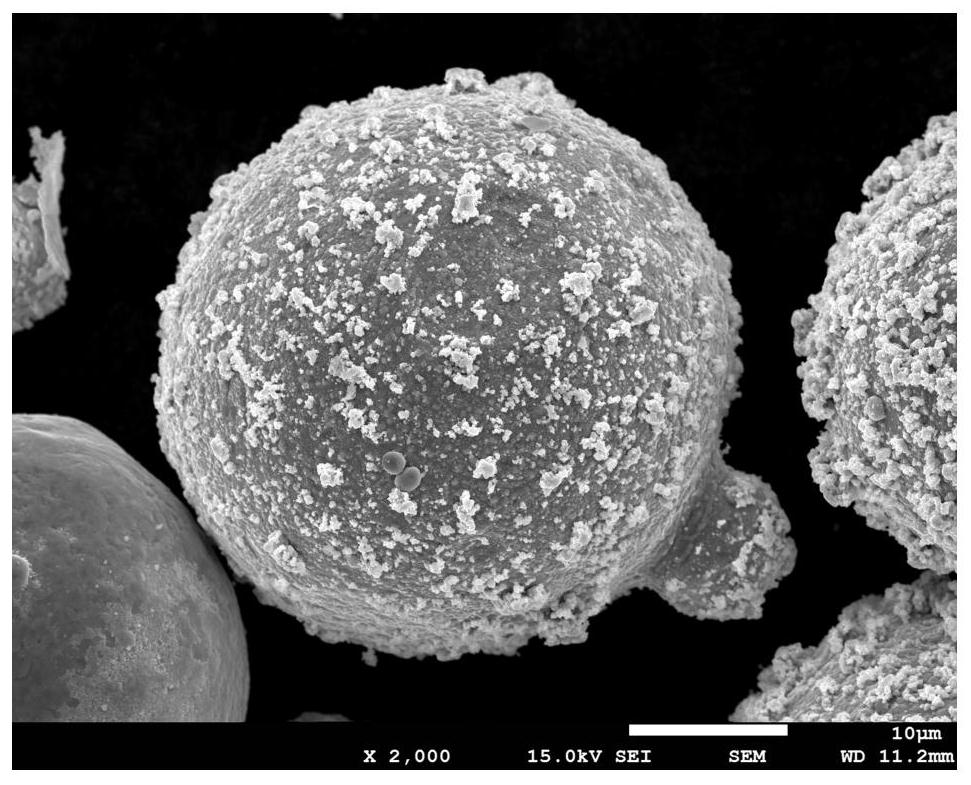

[0056] The difference between Example 2 and Example 1 is that the titanium powder raw material is changed from irregular hydrogenated dehydrogenation Ti-6Al-4V powder to spherical gas atomized Ti powder, and the reaction stage is loaded with high-purity lanthanum trichloride. The gas velocity of argon gas, boron trichloride gas, and hydrogen gas are 1L / min, 0.6L / min, and 1.5L / min respectively. The preset temperature of the heating system of the container containing lanthanum chloride is 1100°C. The chemical vapor deposition temperature From 900°C to 950°C, the reaction time increased from 60min to 90min.

[0057] figure 2 For LaB in embodiment 2 6 The SEM image of the coated spherical atomized titanium powder, the change of the powder matrix will not affect the coated LaB 6 The introduction of oxygen impurity adsorbent, but with the increase of reaction temperature and coating time, the powder coated LaB 6 The particle size is 500nm-600nm, but it will not have a significan...

Embodiment 3

[0059] The raw material of this embodiment 3 is Ti-Ni alloy powder, and the gas velocity of high-purity argon gas, boron trichloride gas and hydrogen gas loaded with lanthanum trichloride in the reaction stage are 1L / min, 0.6L / min, 1.5L / min, respectively. min, the preset temperature of the heating system of the container containing lanthanum chloride is 1000°C, the chemical vapor deposition temperature is 1150°C, and the reaction time is 120min.

[0060] Obtained LaB 6 SEM image of coated Ti-Ni alloy powder and figure 1 Similarly, changes in the powder matrix do not affect coated LaB 6 The introduction of oxygen impurity adsorbent, but with the increase of reaction temperature and coating time, the powder coated LaB 6 The particle size is 800nm-900nm, but it will not have a significant impact on coating uniformity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com