Preparation method of methyl eugenol

A technology of eugenol methyl ether and eugenol, which is applied in the field of preparation of eugenol methyl ether, can solve the problems of low product purity, inability to balance yield and cost, etc., and achieve benefits to yield, reduce energy consumption, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The preparation method of a clove phenolin, including the following steps:

[0042] a. Match 8.4g of sodium hydroxide and 75g of water into about 10%concentration of alkali and add it to the reactor, stir down and add 24.6g clove phenol;

[0043] b. The reaction temperature is controlled at 20 ° C, and slowly dripped 22.8g of sulfate dihydrin under fierce stirring, about 1h drop;

[0044] c. After dripping, after the stirring reaction is 1h, the increase temperature to 40 ° C reacts 1h to decompose sulfuric acid dihydrin;

[0045] d. Subticiency, organic phase decompression distillation is the product.

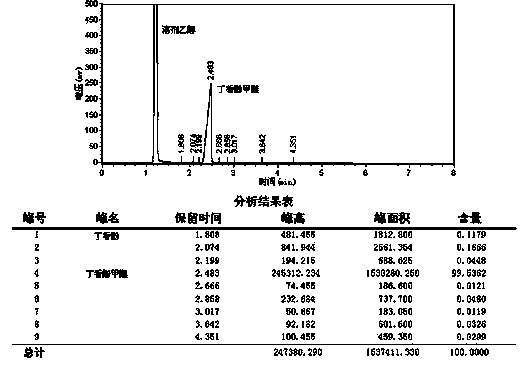

[0046] The product is 24.87g of colorless transparent liquid, and the yield is 93.0%, such as figure 1 The GC purity is 99.53%.

Embodiment 2

[0048] The preparation method of a clove phenolin, including the following steps:

[0049] a. Match 9.6g of sodium hydroxide and 90g of water into about 10%concentration of alkali solution and add the reactor, stir down and add 24.6g clove phenol;

[0050] b. The reaction temperature is controlled at 20 ° C, and slowly dripped 22.8g of sulfate dihydrin under fierce stirring, about 1h drop;

[0051] c. After dripping, after the stirring reaction is 1h, the increase temperature to 40 ° C reacts 1h to decompose sulfuric acid dihydrin;

[0052] d. Subticiency, organic phase decompression distillation is the product.

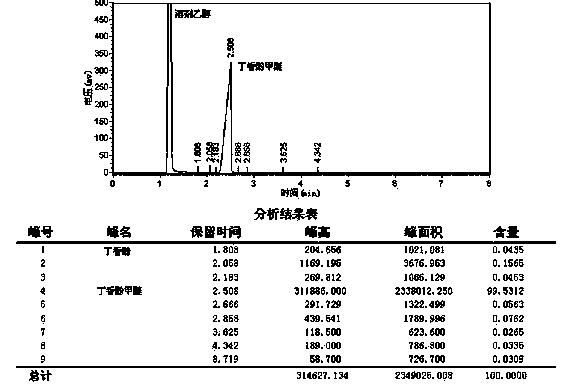

[0053] The product is 25.37g of colorless transparent liquid, and the yield is 94.9%, such as figure 2 The GC purity is 99.53%.

Embodiment 3

[0055] The preparation method of a clove phenolin, including the following steps:

[0056] a. Match 16.8g of sodium hydroxide and 150g of water into about 10%concentration of alkaline solution and add the reactor, stir down and add 49.2g clove phenol;

[0057] b. The reaction temperature is controlled at 20 ° C, and slowly dripped and add 45.6g of sulfate diacerne, about 1.5h dripping;

[0058] c. After dripping, after the stirring reaction is 1h, the increase temperature to 50 ° C reacts 1h to decompose sulfuric acid dihydrin;

[0059] d. Subticiency, organic phase decompression distillation is the product.

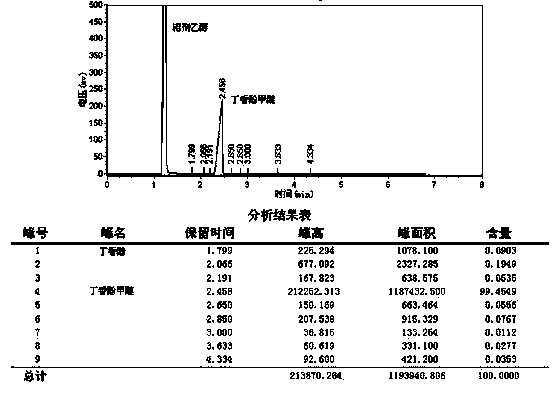

[0060] The product is colorless transparent liquid 49.1g, and the yield is 91.8%, such as image 3The GC purity is 99.45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com