Preparation method for 3-(2-isopropyl chloride) phosphate ester fire-retardant with high resistance to hydrolysis

A chloroisopropyl, hydrolysis-resistant technology, applied in the direction of phosphorus organic compounds, etc., can solve the problems of not mentioning the hydrolysis resistance of TCPP, the method of reducing the hydrolysis resistance of TCPP, and not mentioning it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] 2. Preparation of TCPP crude product:

[0034] According to the existing known process, add aluminum trichloride catalyst into phosphorus oxychloride, stir until the catalyst dissolves, then add propylene oxide dropwise at 65°C, keep the reaction temperature at 60-70°C, after adding propylene oxide dropwise, Continue the reaction at 80°C for 1.5 hours to obtain the crude product of TCPP.

Embodiment 1

[0041] 1) Add 500 grams of TCPP crude product and 50 grams of deionized water into a 1000-liter four-neck bottle equipped with a thermometer and a dropping funnel, stir and adjust the temperature to 0°C, and drop a hydrochloric acid solution with a concentration of 0.1N from the dropping funnel , after adjusting the pH to 5, control the temperature at 0°C, and continuously stir and hydrolyze for 90 minutes under acidic conditions to obtain the reaction liquid; Adjust the pH to 8 or 9 with sodium hydroxide solution, stir for half an hour, and then separate the upper alkaline water layer after standing for half an hour; Wash twice at 90°C, remove the water layer, vacuum distill and dehydrate, and filter to obtain TCPP with high hydrolysis resistance.

Embodiment 2-7

[0043] The implementation method is as in Example 1. After adding the materials, by adjusting different reaction temperatures in step 1), adjusting different pH values, and continuously stirring and hydrolyzing different reaction times, as in Example 1, each example of high hydrolysis-resistant TCPP is prepared.

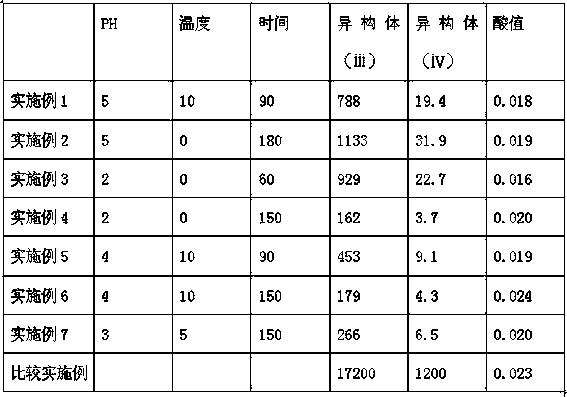

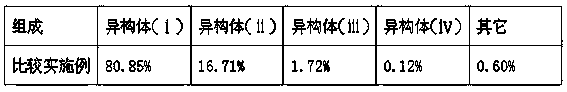

[0044] Table 2. Different preparation conditions and easily hydrolyzed isomer component content and acid value

[0045]

[0046] Note: The unit of isomer content is parts per million (ppm); the unit of acid value is milligrams of potassium hydroxide per gram (mgKOH / g).

[0047] It can be seen that the content of isomers (iii) and (iv) is greatly reduced by the method of the present invention.

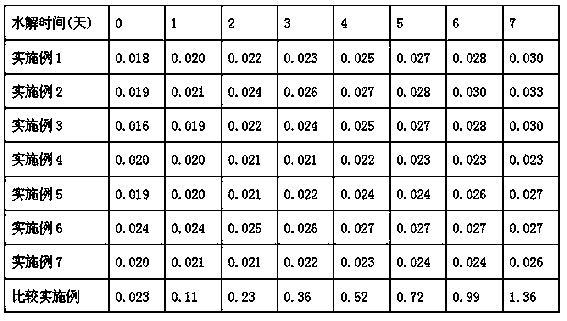

[0048] Table 3. TCPP hydrolysis resistance test data

[0049]

[0050] Note: The test data of hydrolysis resistance is the acid value, and the unit is milligram potassium hydroxide per gram (mgKOH / g).

[0051] It can be seen that the hydrolysis resistance of TCPP is gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com