Degradable environmental-friendly mulching film and preparation method thereof

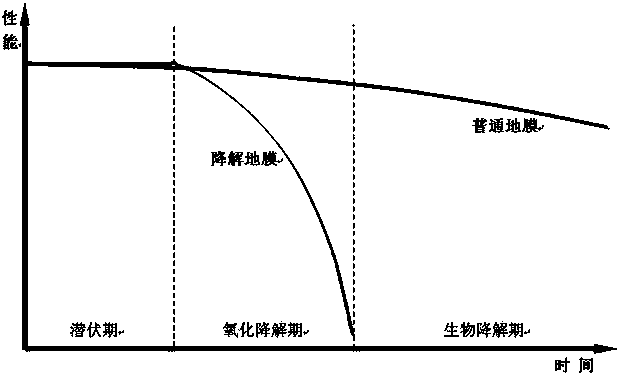

A mulching and environmental protection technology, applied in plant protection cover, climate change adaptation, etc., can solve the problems of complex processing, high cost, poor time control of degradation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

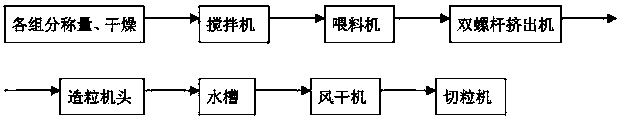

Method used

Image

Examples

Embodiment 1

[0051] Example 1 Preparation of common type environmental protection plastic film

[0052] 1.1 Components and dosage of photothermal biodegradable multi-component composition (percentage by weight)

[0053] TiO 2 30

[0057] Antioxidant 246 20

[0058] GW944 1

[0059] N-Lauroyl Glutamic Acid 3

[0060] In the above formula, TiO 2 For the anatase crystal structure, TiO 2 Perform coating. The chemical name of antioxidant 246 is 2,4,6-tri-tert-butylphenol. GW944 is a hindered amine light stabilizer, the chemical name is poly-{[6-[(1,1,3,3-tetramethylbutyl)-imino]-1,3,5-triazine-2,4 -Diyl][2-(2,2,6,6-tetramethyl-4-piperidinyl)-nitrilo]-hexamethylene-[4-(2,2,6,6-tetramethyl Base-4-piperidinyl)-nitrilo]}.

[0061] 1.2 Ordinary degradable masterbatch

[0062] The various components described in 1.1 are weighed according to the weight percentage of each component, an...

Embodiment 2

[0068] Example 2 Preparation of slow-speed environmental protection film

[0069] 2.1 Components and dosage (percentage by weight) of photothermal biodegradable multi-component composition - slow type

[0071] Calcium stearate 5

[0072] Zinc stearate 5

[0073] Antioxidant 264 20

[0074] GW944 20

[0075] In the above formula, the chemical name of antioxidant 264 is 2,6-di-tert-butyl-4-methylphenol.

[0076] 2.2 Slow degradable masterbatch

[0077] The various components described in 2.1 are weighed according to the weight percentage of each component, and each component is dried separately, and then put into a shear mixer, and the components are physically fused and chemically reacted by using high shear force. Add the mixed material to low-melting low-density polyethylene (such as ExxonMobil LD654 in the United States, with a melting point of 96) in a proportion of 5%. o In C), add a twin-screw granulator to make a slow degradable mast...

Embodiment 3

[0083] Example 3 Rapid environmental protection film

[0084] 3.1 Components and dosage of photothermal biodegradable multi-component composition (weight percent)

[0085] TiO 2 30

[0086] Cobalt stearate 40

[0087] Antioxidant BHA 10

[0088] N-Lauroyl Glutamic Acid 20

[0089] In the above formula, TiO2 has an anatase crystal structure, and organic matter is used as the coating material of TiO2, such as polyethylene glycol and triethanolamine. The chemical name of the antioxidant BHA is tert-butylhydroxyanisole.

[0090] 3.2 Rapid Degradable Masterbatch

[0091] The various components described in 3.1 are weighed according to the weight percentage of each component, and each component is dried separately, and then put into a shear mixer, and the components are physically fused and chemically reacted by using high shear force. Add the mixed material to low-melting low-density polyethylene (such as Exxon Mobil LD654 in the United States, with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com