Preparation method of self-cleaning cotton fabric based on light-induced polymer free radicals for degrading pollutants

A polymer and free radical technology, applied in the direction of plant fibers, can solve the problems of poor fiber feel, easy to fall off, difficult fiber surface uniform dispersion, etc., and achieve excellent mechanical properties and high fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Self-cleaning cotton fabric manufacturing method based on photopolymer free radical degradation pollutants:

[0034] Preparation of degradable pollutant cotton fabric:

[0035] 1) Add 15 g of sulfonated polyether ether ketone with a degree of sulfonation of 70.3% to 500 mL of deionized water, and heat to 50°C under ultrasonic environment to dissolve;

[0036] 2) Add 5g of polyvinyl alcohol to 500mL of deionized water, swell in cold water for 2h, then heat to 85°C and stir to dissolve;

[0037] 3) Add the dissolved sulfonated polyether ether ketone to the dissolved polyvinyl alcohol, heat to 70°C, add HCl to adjust the pH to 2.3, add 6wt% of the crosslinking agent glutaraldehyde after 5 minutes, and stir vigorously 5min, configure into 1L finishing solution, and cool to room temperature;

[0038] 4) Dip a square piece of cotton cloth in the cooled finishing solution, control the bath ratio to 1:20, immerse for 50 minutes and then roll the solution, one dip and one roll, the roll ...

Embodiment 2~ Embodiment 5

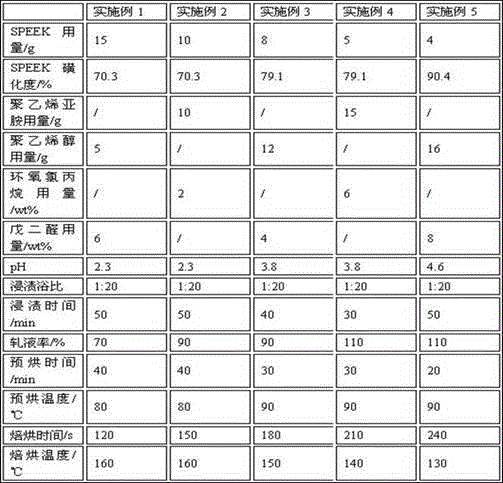

[0052] Change the amount of SPEEK and H donor per 1L of finishing solution, the sulfonation degree of SPEEK, pH value, the amount of crosslinking agent, immersion time, rolling rate, pre-baking temperature and time, baking temperature and time.

[0053]

[0054] Table 1. Process formula of each embodiment

[0055]

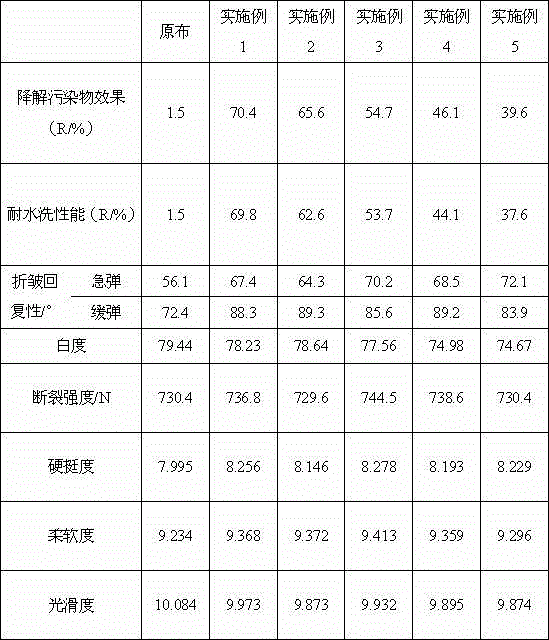

[0056] Table 2. Performance test of cotton fabric treated in each embodiment

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com