Dynamic testing device and method for ablation rate of material

A dynamic testing and testing device technology, applied in material excitation analysis, electrical excitation analysis, etc., can solve the problem that the anti-interference ability of the laser receiver, the stability of the bench and the feeding accuracy are quite high and cannot be well characterized. The problem of measuring the ablation material line, lack of dynamic ablation experiments, etc., achieves the effect of easy control of the test temperature, good safety, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

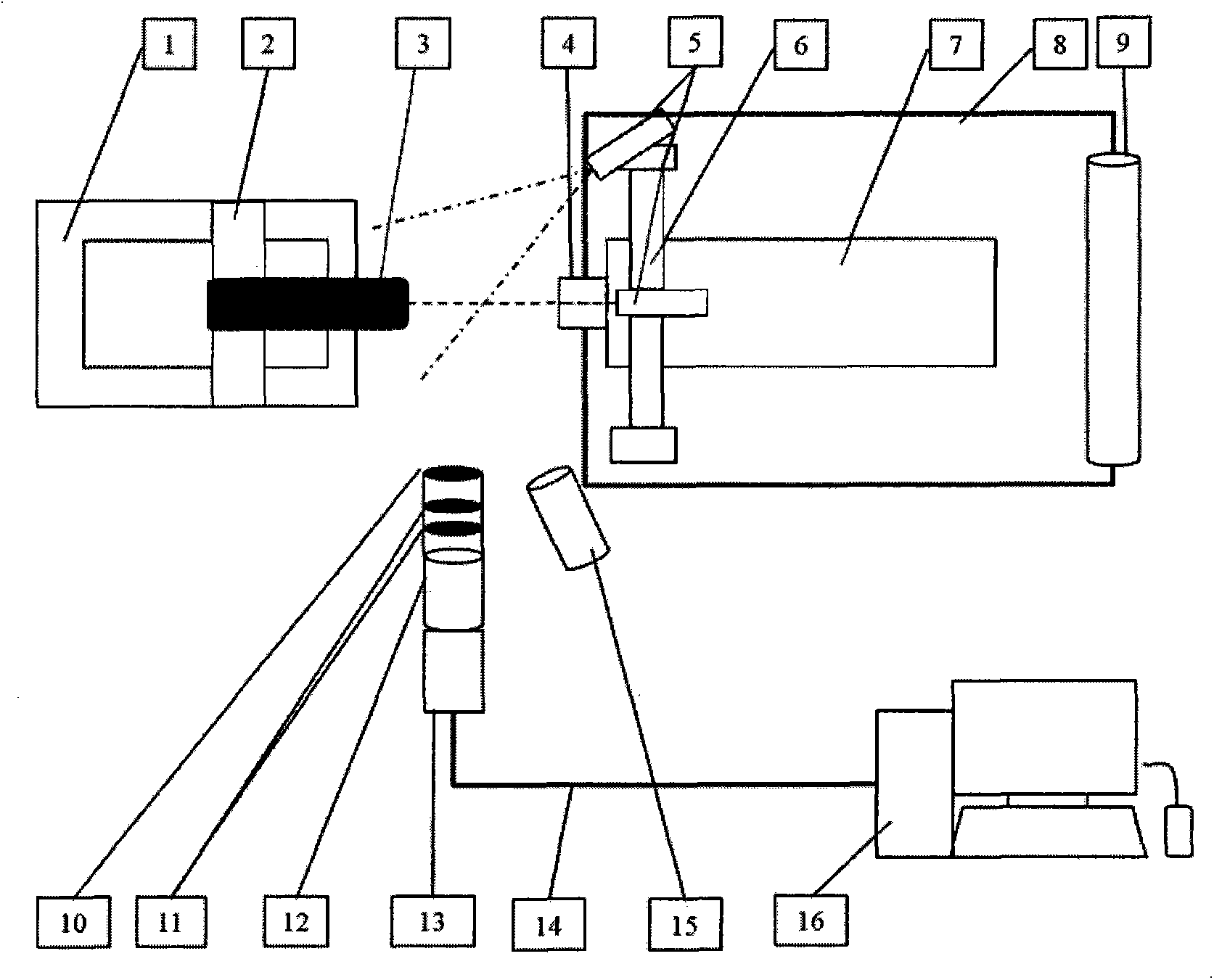

[0025] This embodiment is a dynamic test device for ablation rate of materials, mainly comprising: a horizontal moving platform 1; a vise 2 is fixed on the horizontal moving platform 1 with bolts; the ablation material 3 to be tested is clamped by the vise 2; A positioning bracket 6 is installed at a certain distance from the horizontal mobile platform 1; the U-shaped clamp on the positioning bracket 6 clamps the arc heating spray gun 7; The two inline lasers 5 can form a positioning cross-structure laser on the axial end face of the ablation material 3 to be measured; the nozzle of the arc heating spray gun 7 is threaded to connect the water cooling jacket 4; the water cooling jacket 4 passes through the water pipe 8 and the circulation The water tank 9 is connected; the nozzle of the arc heating spray gun 7 faces the ablation material 3 to be tested at a certain distance; a CCD camera 13 is installed on one side of the ablation material to be measured and the axis of the arc ...

Embodiment 2

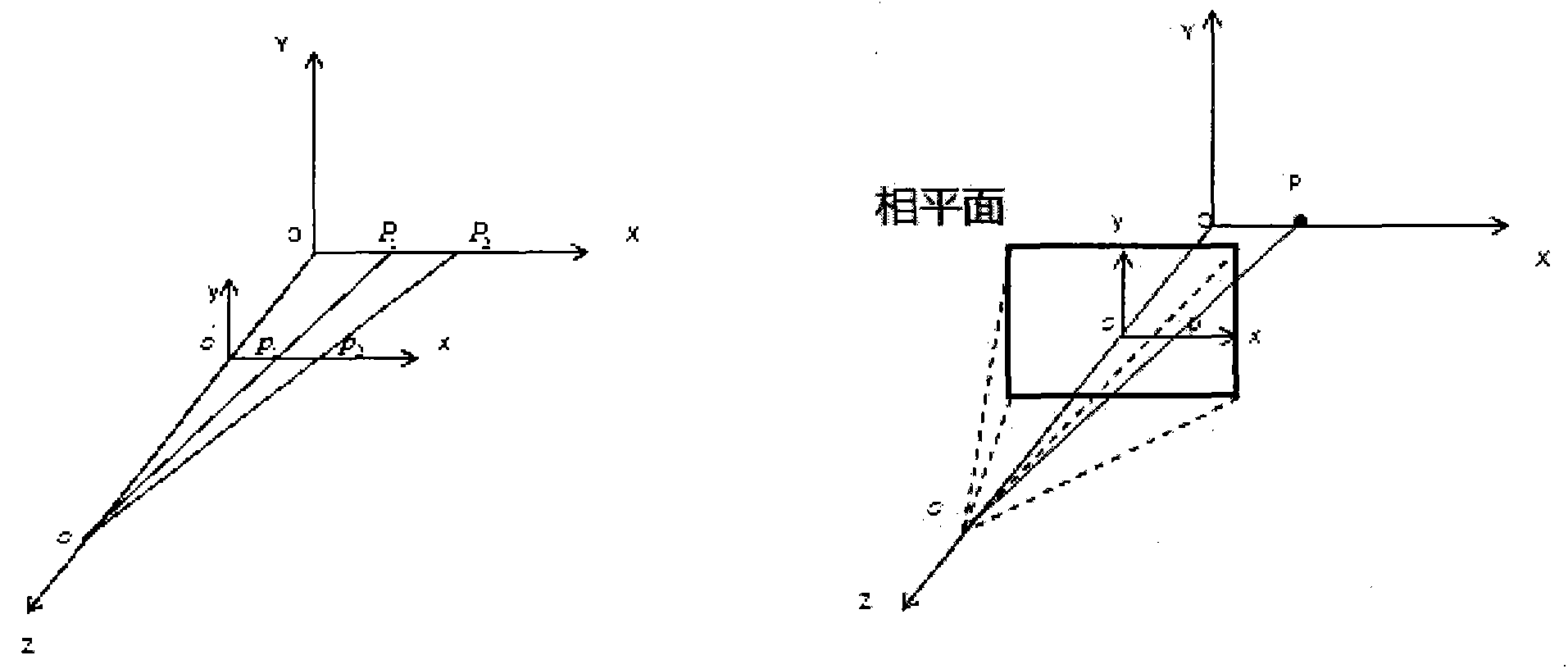

[0030] The principle of image processing:

[0031] The central axis of the ablation material to be tested is the same as the direction of flame injection, which is set as the X axis, the vertical direction is established as the Y axis, and the direction perpendicular to the XOY plane is set as the Z axis, as figure 1 As shown; the camera is placed on the Z axis so that the phase plane of the camera is parallel to the X axis, which is convenient for image processing; the filter group is installed in front of the lens of the CCD camera with various focal lengths; a 405nm filter is installed on the Z axis and the Y axis direction For the Ziguang inline laser emitter, the laser projection planes are respectively located in the XOZ and XOY planes, so that the two laser beams form a positioning cross-structure laser on the end surface of the ablation material to be tested; the two laser emitters actually emit two A fan-shaped area, the intersection line of which is located on the X-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com