Composite substrate with isolation layer and manufacturing method thereof

A composite substrate and manufacturing method technology, applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, crystal growth and other directions, can solve the problems of difficulty in forming a lattice structure, poor environmental protection, and complicated preparation methods for silicon SOI substrates, etc. Achieve the effect of improving performance and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

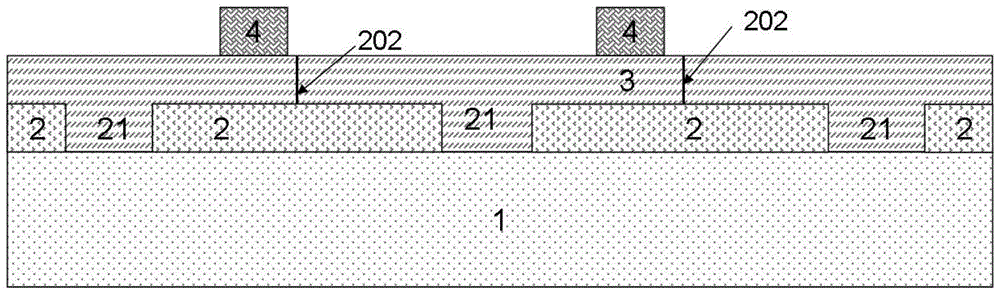

[0033] This embodiment provides a method for manufacturing a silicon SOI substrate with an insulating isolation layer, and its process flow is as follows Figure 1-7 shown, including:

[0034] 1) if figure 1 As shown, a 300nm thick SiO is formed on the surface of the silicon substrate 1 by thermal oxidation. 2 Thin film is used as the first sub-isolating layer 2, and then a plurality of openings 21 are formed in the first sub-isolating layer 2 by photolithography and etching processes, exposing the surface of the silicon substrate 1, and the plurality of openings 21 form a grating pattern, and its period is 4 microns, the width of the opening 21 is 1 micron;

[0035] 2) if figure 2 As shown, using the CVD lateral epitaxial growth technology, the silicon substrate 1 exposed at the opening 21 is used as a seed to prepare a silicon thin film as a seed layer 3, and the seed layer 3 starts epitaxial growth from the silicon substrate 1 at a plurality of openings 21, Then later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com