Silicon/aligned carbon nanotube composite negative electrode material for lithium ion battery and preparation method thereof

A technology of oriented carbon nanotubes and lithium-ion batteries, applied in battery electrodes, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problem that the structural skeleton is not easy to design and control, and limit the performance improvement of composite negative electrode materials Space, low performance of lithium-ion battery anode materials and other issues, to achieve excellent conductivity, fast lithium-ion mobility, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

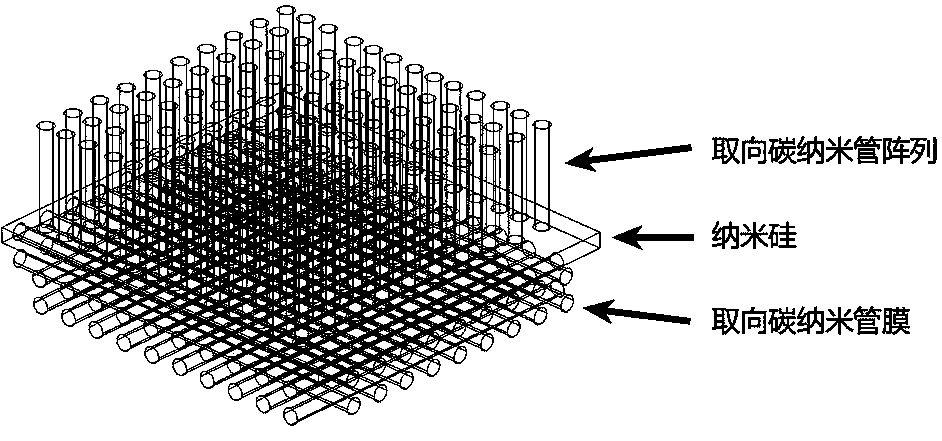

Image

Examples

Embodiment 1

[0028] Catalyst layer deposited by electron beam evaporation process on silicon substrate with structure of Al 2 o 3 / Fe. Among them, Al 2 o 3 The thickness is 5 nm, and the Fe thickness is 1.2 nm. Using chemical vapor deposition method, ethylene is used as carbon source, hydrogen is used as reducing gas, and argon is used as carrier gas to synthesize aligned carbon nanotube arrays on silicon substrate with catalyst. The flow rate of ethylene was 90 sccm, the flow rate of argon gas was 400 sccm, the flow rate of hydrogen gas was 30 sccm, the growth temperature was 740 ℃, and the growth time was 10 min. From the array of aligned carbon nanotubes, the film can be directly drawn to obtain a monolayer of single-oriented carbon nanotubes, and 20 layers of aligned carbon nanotubes with a thickness of about 400 nm can be obtained by stacking 20 layers in sequence. Nano-silicon was prepared by electron beam evaporation with a deposition rate of 0.8 ? / s, and a 100 nm-thick nano-si...

Embodiment 2

[0030] Catalyst layer deposited by electron beam evaporation process on silicon substrate with structure of Al 2 o 3 / Fe. Among them, Al 2 o 3 The thickness is 5 nm, and the Fe thickness is 1.2 nm. Using chemical vapor deposition method, ethylene is used as carbon source, hydrogen is used as reducing gas, and argon is used as carrier gas to synthesize aligned carbon nanotube arrays on silicon substrate with catalyst. The flow rate of ethylene was 90 sccm, the flow rate of argon gas was 400 sccm, the flow rate of hydrogen gas was 30 sccm, the growth temperature was 740 ℃, and the growth time was 10 min. From the array of aligned carbon nanotubes, the film can be directly drawn to obtain a monolayer of single-oriented carbon nanotubes, and 8 layers of aligned carbon nanotubes with a thickness of about 160 nm can be obtained by stacking 8 layers in sequence. Nano-silicon was prepared by electron beam evaporation with a deposition rate of 0.8 ? / s, and a 100 nm-thick nano-sili...

Embodiment 3

[0032] Catalyst layer deposited by electron beam evaporation process on silicon substrate with structure of Al 2 o 3 / Fe. Among them, Al 2 o 3 The thickness is 5 nm, and the Fe thickness is 1.2 nm. Using chemical vapor deposition method, ethylene is used as carbon source, hydrogen is used as reducing gas, and argon is used as carrier gas to synthesize aligned carbon nanotube arrays on silicon substrate with catalyst. The flow rate of ethylene was 90 sccm, the flow rate of argon gas was 400 sccm, the flow rate of hydrogen gas was 30 sccm, the growth temperature was 740 ℃, and the growth time was 10 min. From the array of aligned carbon nanotubes, the film can be directly drawn to obtain a monolayer of single-oriented carbon nanotubes, and 8 layers of aligned carbon nanotubes with a thickness of about 160 nm can be obtained by stacking 8 layers in sequence. Nano-silicon was prepared by electron beam evaporation with a deposition rate of 0.8 ? / s, and a 400 nm-thick nano-sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com