Coating solution for forming polyimide film, liquid crystal alignment agent, polyimide film, liquid crystal alignment film, and liquid crystal display element

A polyimide film, polyimide technology, applied in coatings, instruments, optics, etc., can solve problems such as poor printing, inability to freely use diamine components, and burn-in

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0140] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in more detail, explanation of this invention is not limited to these Examples.

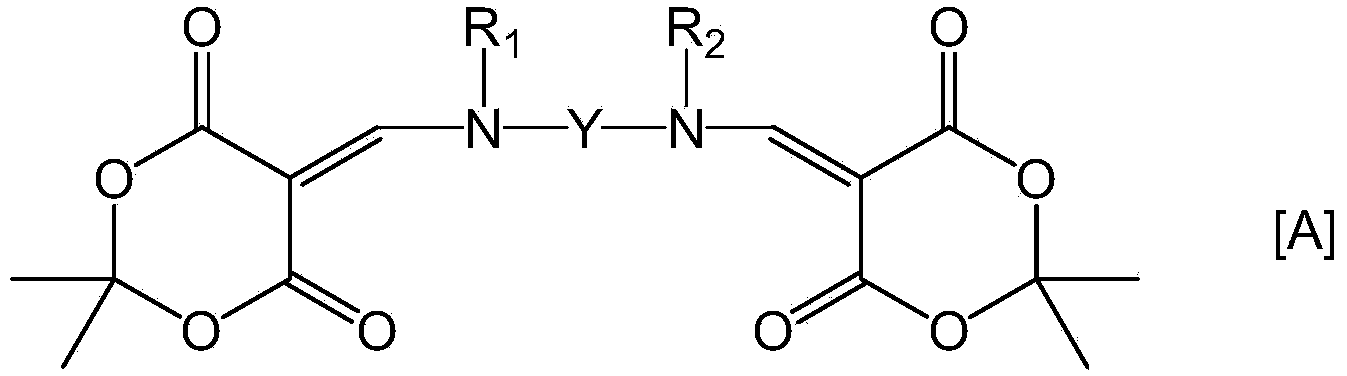

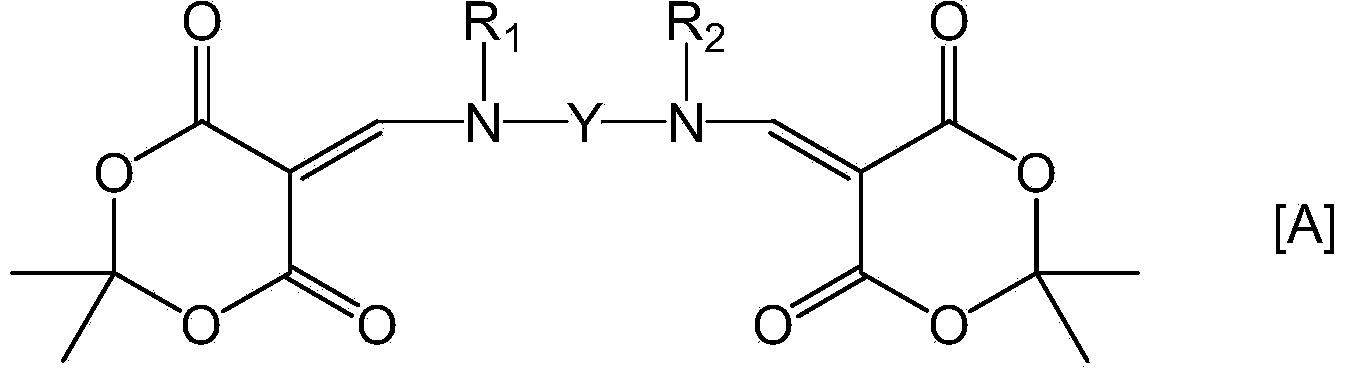

[0141] [Synthesis of bifunctional compound represented by the above formula [A]]

Synthetic example 1

[0143] The compound 5,5'-(1,4-phenylenebis(azanediyl))bis(methane-1-yl-1-ylidene)bis(2,2-dimethylene) represented by the following formula [4] Synthesis of 1,3-dioxane-4,6-dione)

[0144] [chem 22]

[0145]

[0146] Michaelis' acid [1] (14.7 g, 102 mmol) and trimethyl orthoformate [2] (147 g) were added to a 300 mL four-necked flask, and heated to reflux for 1 hour. Thereafter, p-phenylenediamine [3] (5.09, 46 mmol) was added, followed by heating to reflux for 2 hours. After completion of the reaction, the reaction solution was cooled to room temperature, and the precipitated solid was filtered, washed with hexane, and then dried to obtain 15.8 g of compound [4] (yield 82%).

[0147] 1 H-NMR (400MHz, DMSO-d6, δppm): 11.29(2H,d), 8.56(2H,d), 7.64(4H,s), 1.68(12H,s).

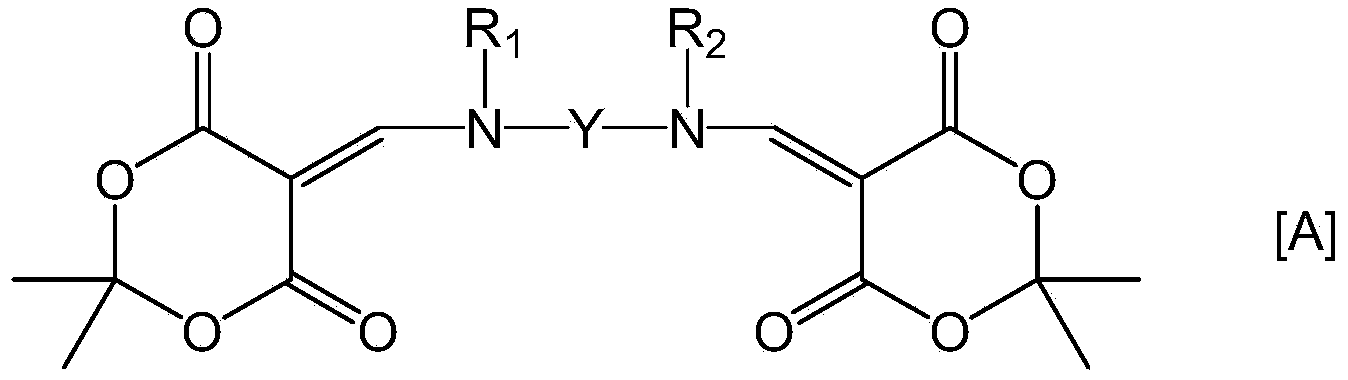

Synthetic example 2

[0149] The compound 5,5'-(1,3-phenylenebis(azanediyl))bis(methane-1-yl-1-ylidene)bis(2,2-dimethylene) represented by the following formula [6] Synthesis of 1,3-dioxane-4,6-dione)

[0150] [chem 23]

[0151]

[0152] Michaelis' acid [1] (14.R, 102 mmol) and trimethyl orthoformate [2] (1479) were added to a 300 mL four-neck flask, and heated to reflux for 1 hour. Then, m-phenylenediamine [5] (5.09, 46 mmol) was added, followed by heating to reflux for another 2 hours. After completion of the reaction, the reaction solution was cooled to room temperature, and the precipitated solid was filtered, washed with hexane, and then dried to obtain 14.1 g of compound [6] (yield 72%).

[0153] 1 H-NMR (400MHz, DMSO-d6, δppm): 11.28(2H,s), 8.74(2H,s), 7.98(1H,s), 7.44(3H,s), 1.68(12H,s).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com