Method for propylene preparation through methanol conversion

A technology for methanol conversion and propylene, applied in chemical instruments and methods, hydrocarbon production from oxygen-containing organic compounds, organic chemistry, etc., can solve the problems of poor catalyst stability and low propylene selectivity, improve catalyst stability, overcome catalyst The effect of poor stability and reduced degree of coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

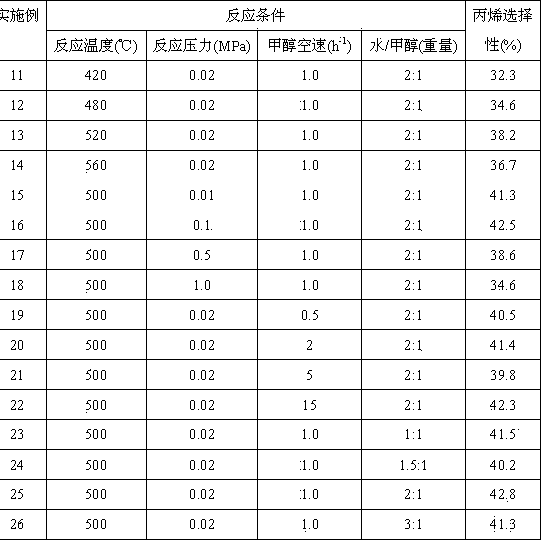

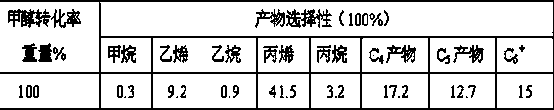

Examples

Embodiment 1

[0015] With tetrapropylammonium bromide as the template, aluminum nitrate as the aluminum source, and silica sol as the silicon source, the raw materials are first molarally mixed with SiO 2 / Al 2 o 3 =200;OH - / SiO 2 =0.3; R / SiO 2 =0.5;H 2 O / SiO 2 = 40 mixed in a ratio of 40, hydrolyzed completely at room temperature, put into a stainless steel reactor, controlled the growth direction of molecular sieve crystals under hydrothermal conditions, and crystallized at 100°C for 60 hours to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 200 and a shape index of 50.

[0016] Take by weighing 40 grams of NaZSM-5 molecular sieves prepared above, 25 grams of silica sol (SiO 2 40% by weight), mixed with water, extruded into a mold with a diameter of 1.5mm, dried in the air, placed in an oven at 80°C for 8 hours, baked in a muffle furnace at 600°C for 6 hours, and removed the template agent. It was exchanged three time...

Embodiment 2

[0019] Tetrapropylammonium hydroxide is used as a template, aluminum sulfate is used as an aluminum source, water glass is used as a silicon source, and raw materials are molar ratios of SiO 2 / Al 2 o 3 =500;OH - / SiO 2 =0.05; R / SiO 2 =1.5;H 2 O / SiO 2 = 10, using the method described in Example 1, crystallized at 80°C for 100 hours to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 500 and 3.

[0020] Take by weighing 30 grams of NaZSM-5 molecular sieves prepared above, 38 grams of silica sol (SiO 2 40% by weight) and 15 grams of alumina, mixed with water, extruded into a mold with a diameter of 1.5 mm, dried in the air, placed in an oven at 100 ° C for 5 hours, and roasted in a muffle furnace at 600 ° C for 4 hours. The template was removed, exchanged three times in 10% ammonium chloride solution at 85°C, dried and calcined in a muffle furnace at 500°C for 8 hours to obtain a HZSM-5 molecular sieve catalyst...

Embodiment 3

[0023] Tetraethylammonium chloride is used as a template, sodium aluminate is used as an aluminum source, and tetraethyl orthosilicate is used as a silicon source. The raw material is molar ratio of SiO 2 / Al 2 o 3 =800;OH - / SiO 2 =1.5; R / SiO 2 =0.02;H 2 O / SiO 2= 30, using the method described in Example 1, crystallized at 120 ° C for 50 hours, to obtain the molar ratio of silicon to aluminum SiO 2 / Al 2 o 3 NaZSM-5 molecular sieve with a shape index of 800 and a shape index of 10.

[0024] Take by weighing 10 grams of NaZSM-5 molecular sieves prepared above, 32 grams of silica sol (SiO 2 40% by weight) and 10 grams of aluminum phosphate, mixed with water, extruded into a mold with a diameter of 1.5 mm, dried in the air, placed in an oven at 120 ° C for 8 hours, and roasted in a muffle furnace at 500 ° C for 8 hours. The template agent was removed, exchanged three times in 10% ammonium nitrate solution at 80°C, dried and calcined in a muffle furnace at 600°C for 4 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com