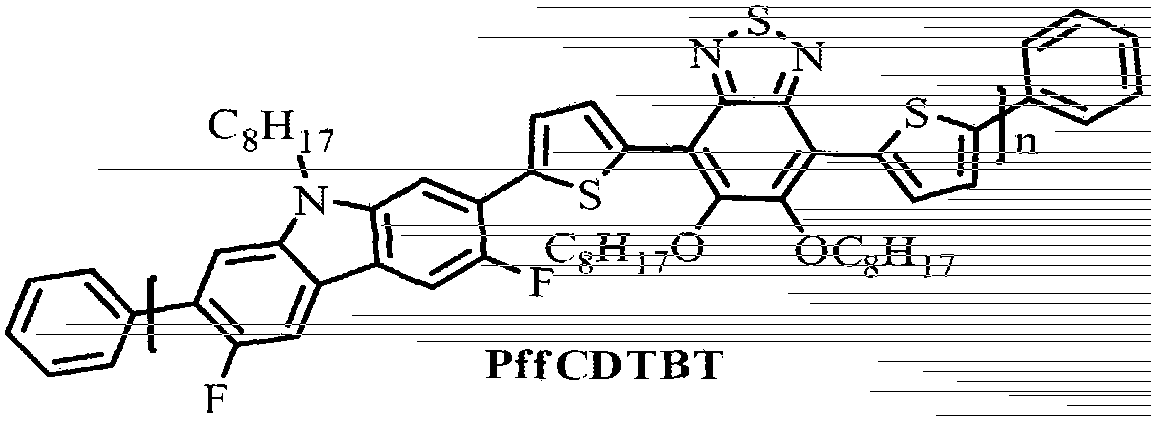

Preparation of novel fluorine-containing narrow band gap conjugated polymer material

A conjugated polymer, narrow bandgap technology, used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc., can solve problems such as rare materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

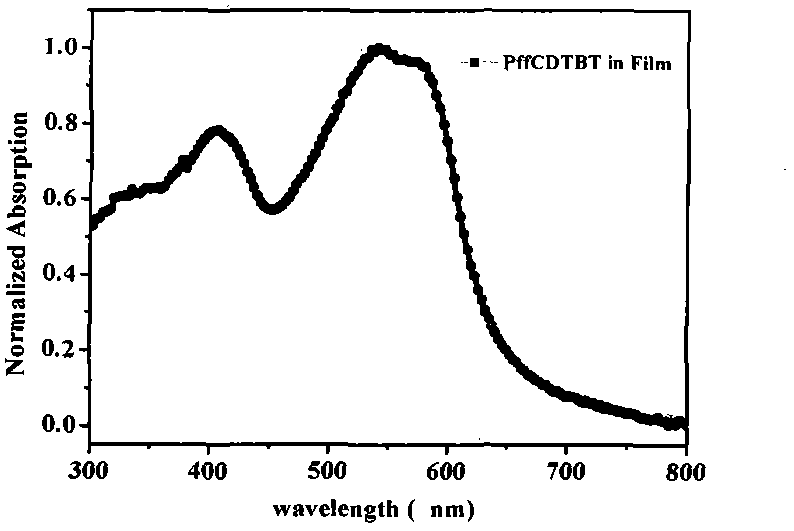

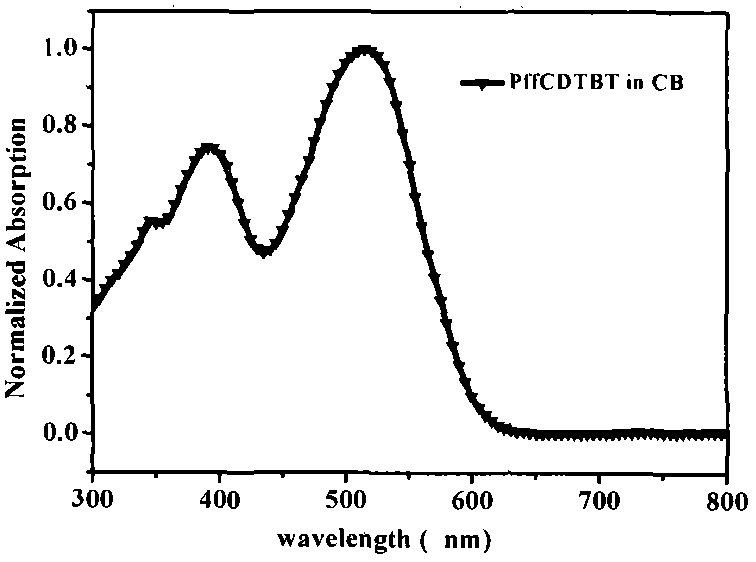

[0014] Example 1: Preparation of fluorine-containing conjugated polymers with the structure of Formula 1

[0015] 200.0 mg monomer M1, 158.78 mg M2, 45 mL THF, 15 mL toluene, 4 mL water, and 0.4 g NaHCO 3 In a 100ML slit-gate flask, add 3.6mg of Pd (PPh 3 ) 4 Before and after, the nitrogen gas was repeatedly filled and degassed, and then the system was stirred and refluxed for 72 hours under a nitrogen atmosphere. Then cool the system, add 10mg phenylboronic acid and 1.8mg Pd(PPh 3 ) 4 Raise the temperature and react for 4 hours, then cool down and add 100 μL of bromobenzene to raise the temperature and continue the reaction overnight to complete capping. After the system was cooled to room temperature, water and chlorobenzene were added; the organic layer was separated with a separatory funnel and washed three times with water. Then heat the organic phase to 100°C to dissolve part of the precipitated polymer, filter the organic phase and rotary evaporate the filtrate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com